Pneumatic radial impact blanking machine

A feeding machine and cutting technology, which is applied in the field of low energy consumption, near-net and high-efficiency precision molding, can solve the problems of poor cutting section quality, low material utilization rate, and low production efficiency, and achieves adjustable frequency, high frequency, and guaranteed section. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

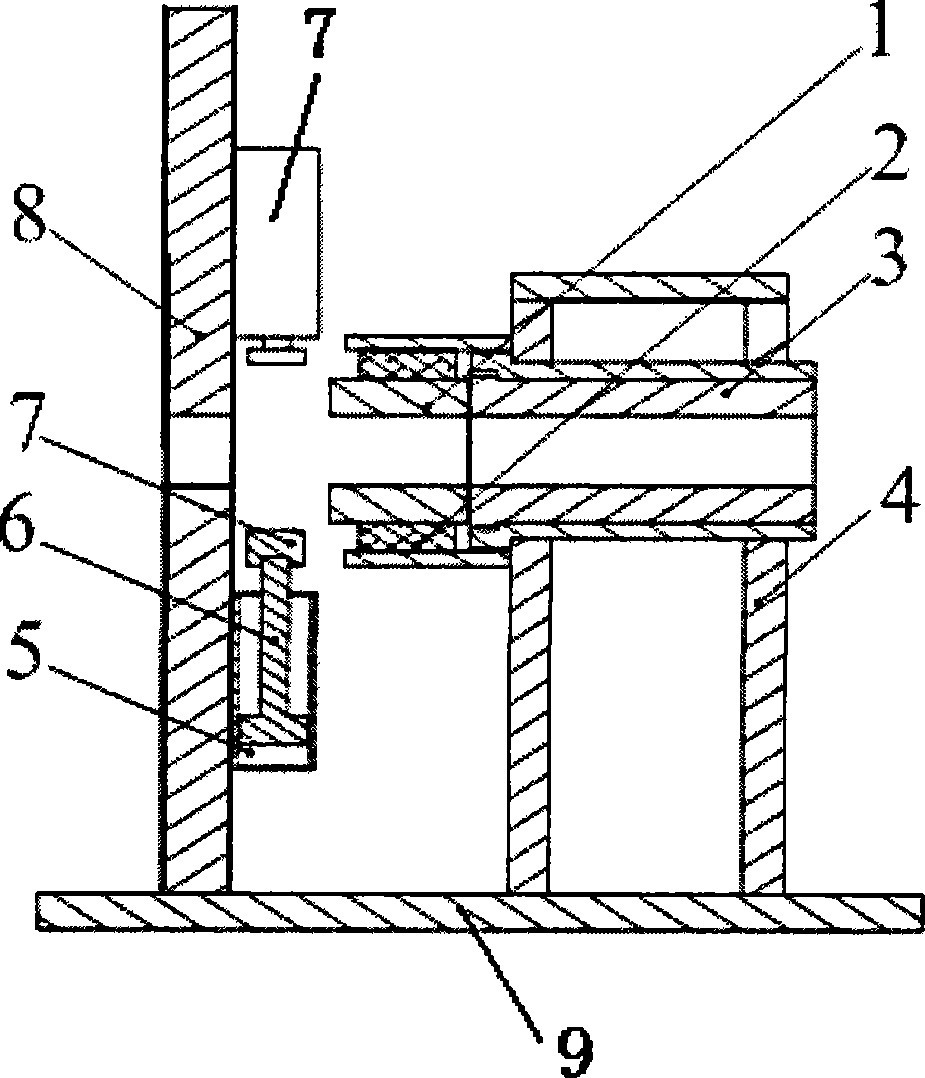

[0015] Referring to the accompanying drawings, the pneumatic radial impact blanking machine of the present invention comprises a base 9, on which a bar stock fixing device and a frame 8 are arranged, and the bar stock fixing device mainly consists of a blanking sleeve 1, a bar stock fixing sleeve 3. The elastic cushion cover 2 and the bar stock fixing bracket 4 are formed. The bar stock fixing cover 3 is connected with the bar stock support 4 through a transition fit, and one end of the blanking sleeve 1 forms a fit with the bar stock fixing bracket 4 through the elastic cushion cover 2;

[0016] 7 impact cylinders 5 are evenly arranged on the frame 8 along the radial direction of the bar. The impact cylinder 5 has a piston 6, and a blanking mold 7 is installed on the piston 6. The working contour curve of the blanking mold 7 adopts a cycloid;

[0017] During the blanking process, one end of the bar is installed in the inner hole of the bar fixing sleeve 3, and the other end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com