One-way driving semi-cracked pipeline fracture simulation experimental device and experimental method

A simulated experimental device and driving technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult, dangerous, and large errors in the preparation of test pieces for pipeline fracture experiments, and achieve reduced work risks, convenient acquisition, and The effect of reducing size error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

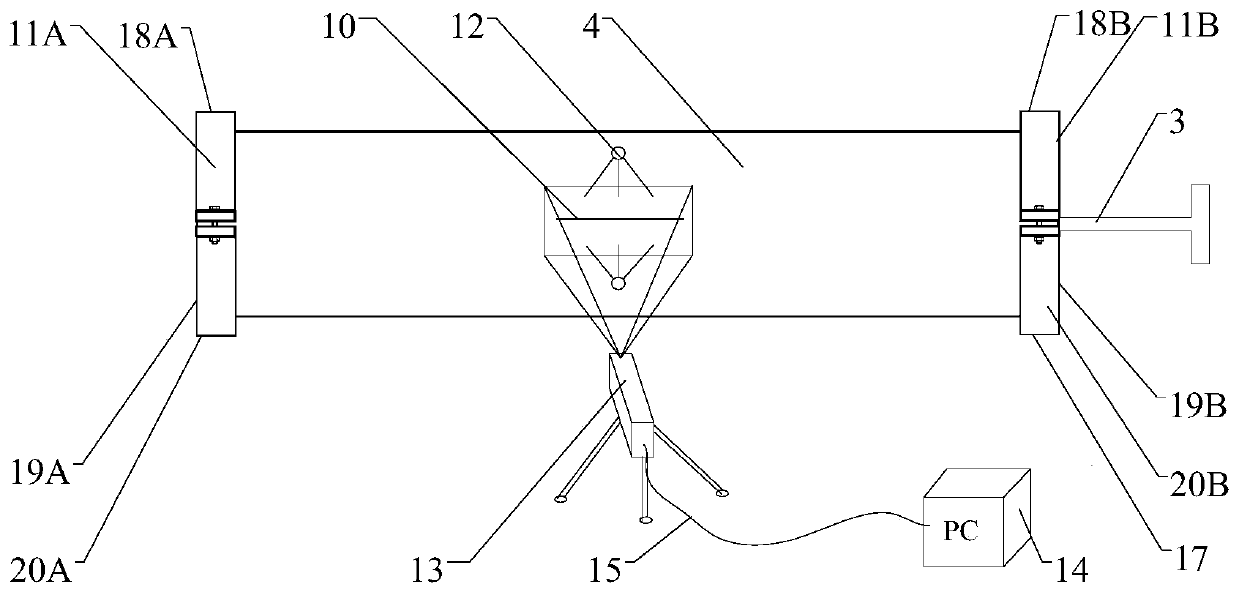

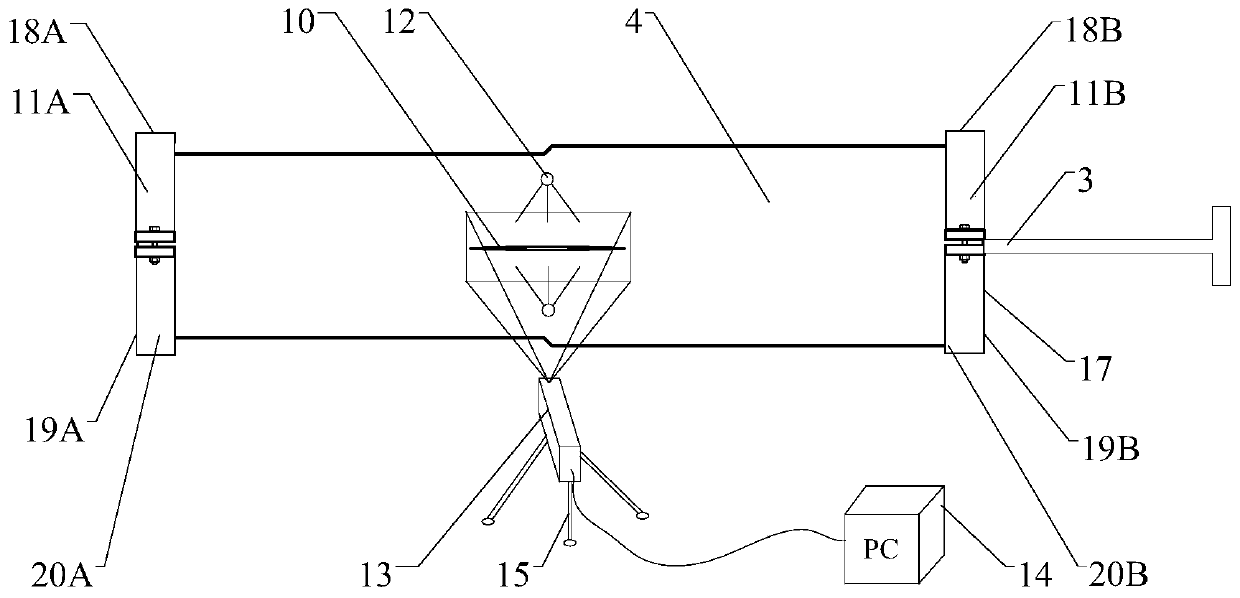

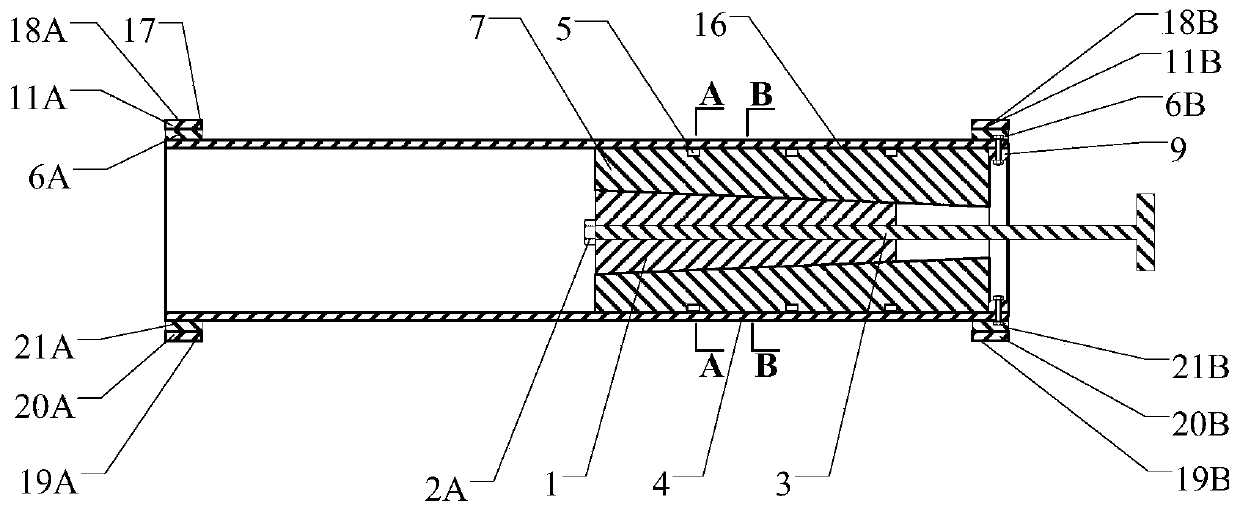

[0027] Such as Figure 1 to Figure 7 As shown, the unidirectional hydraulically driven half-crack pipeline fracture simulation experimental device includes: pipeline support system 17, pipeline expansion system 16, tie rod 3, DIC test system 15; the side wall of experimental pipe section 4 is provided with axial penetration prefabricated Crack 10, pre-crack 10 is symmetric about the axial midplane of the experimental pipe section 4; the pipe support system 17 supports both ends of the experimental pipe section 4; the inner end surface of the pipe expansion system 16 coincides with the axial midplane of the experimental pipe section 4 ; The pipeline expansion system 16 is pulled by the tie rod 3 to expand the sidewall of the experimental pipe section 4, causing the experimental pipe section 4 to fracture; the DIC testing system 15 conducts real-time observation of the fracture process of the experimental pipe section 4.

[0028] Pipe support system 17, including: left upper clamp r...

Embodiment 2

[0038] Such as Figure 8 As shown, the difference between the second embodiment and the first embodiment is that the eight sector blocks 7 are combined to form a cylindrical body with a tapered through hole on the inner wall. The inward end of the tapered through hole has a smaller diameter and the outward end has a larger diameter. Conical block 1 passes through the conical through hole along the central axis, the length of the conical block 1 is less than the length of the conical through hole; the conical block 1 is a truncated cone, the inner end surface is a small diameter end; the conical block 1 and the cone The shape of the through holes are matched with each other; the tie rod 3 passes through the conical block 1 along the central axis, and the tie rod 3 is fixed on the conical block 1 through the first fixing nut 2A and the second fixing nut 2B. The outer end of the tie rod 3 is connected with the hydraulic device. The hydraulic device pulls the pipeline expansion syst...

Embodiment 3

[0041] Such as Figure 9 to Figure 12 As shown, the difference between the unidirectional motor-driven half-crack pipeline fracture simulation experimental device and the second embodiment is that the screw 23 is used instead of the tie rod 3, and the electric motor 22 is used as the power device; the screw 23 and the tapered block 1 rely on threads connection.

[0042] Experimental methods for pipe fracture simulation experiments, such as Figure 11 to Figure 12 As shown, the above-mentioned unidirectional motor-driven half-crack pipeline fracture simulation experimental device is different from the second embodiment in that: during the experiment, the motor 22 provides power to control the screw 23 to rotate around the axial direction, and then the wire The bar 23 converts the rotational movement into the axial rotation movement of the cone block 1 and the linear movement to the left along the axial direction. At the same time, the sector block 7 slowly expands radially outward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com