Two-way hydraulic expansion pipe fracture simulation experimental device and experimental method

A simulated experimental device, two-way hydraulic technology, applied in the direction of measuring device, applying stable tension/pressure to test material strength, instruments, etc., can solve the problems of difficult preparation, high risk and high cost of pipeline fracture test specimens, and achieve The effects of reducing work risk, facilitating access, and reducing size errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

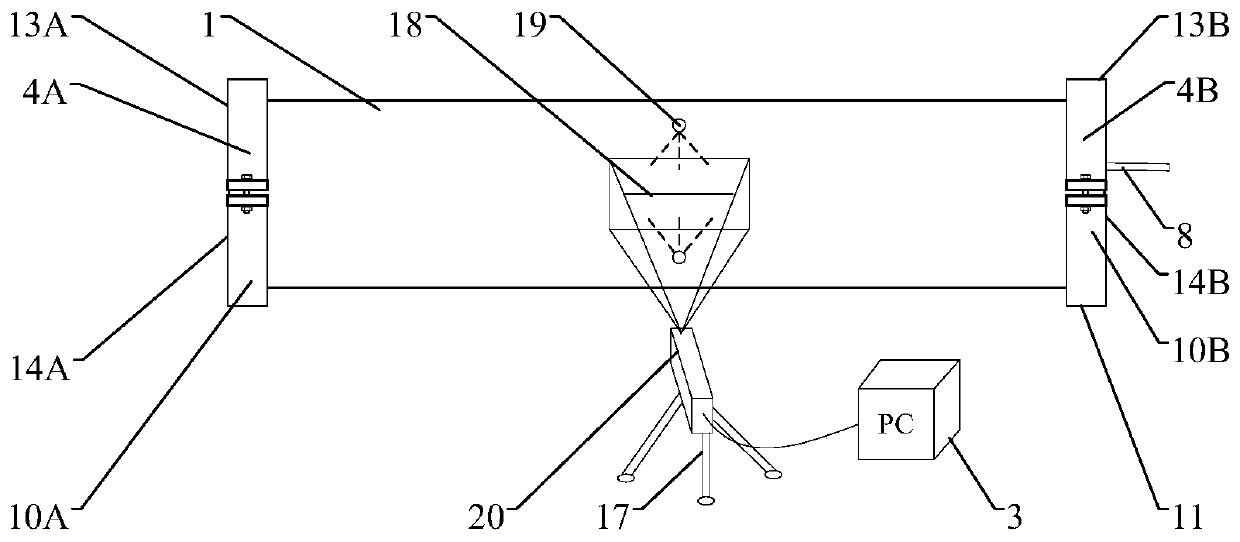

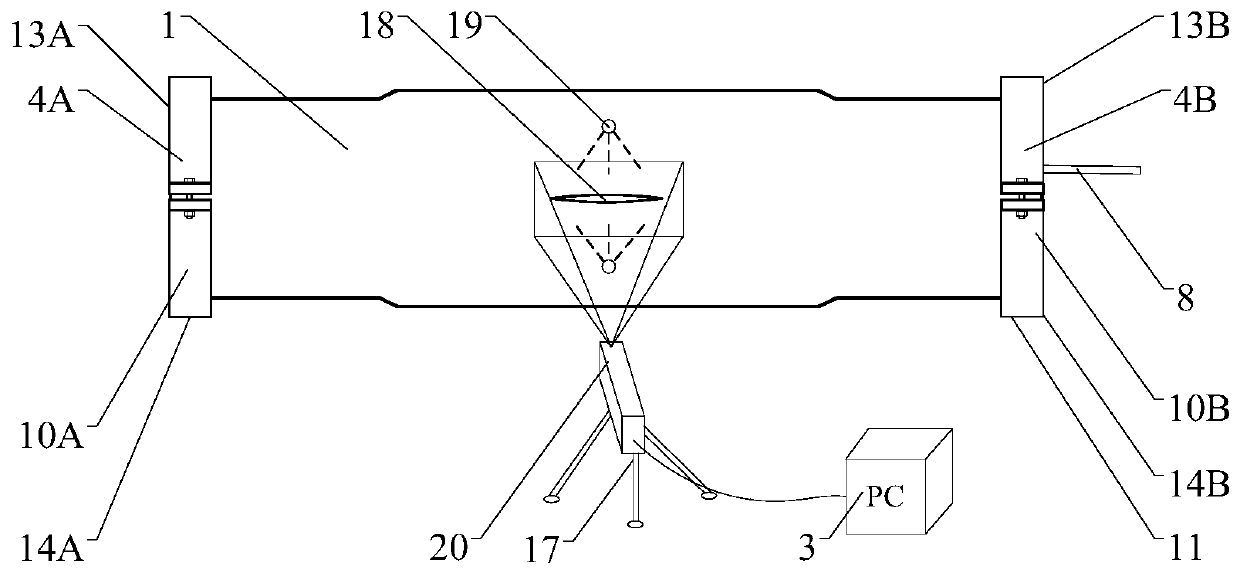

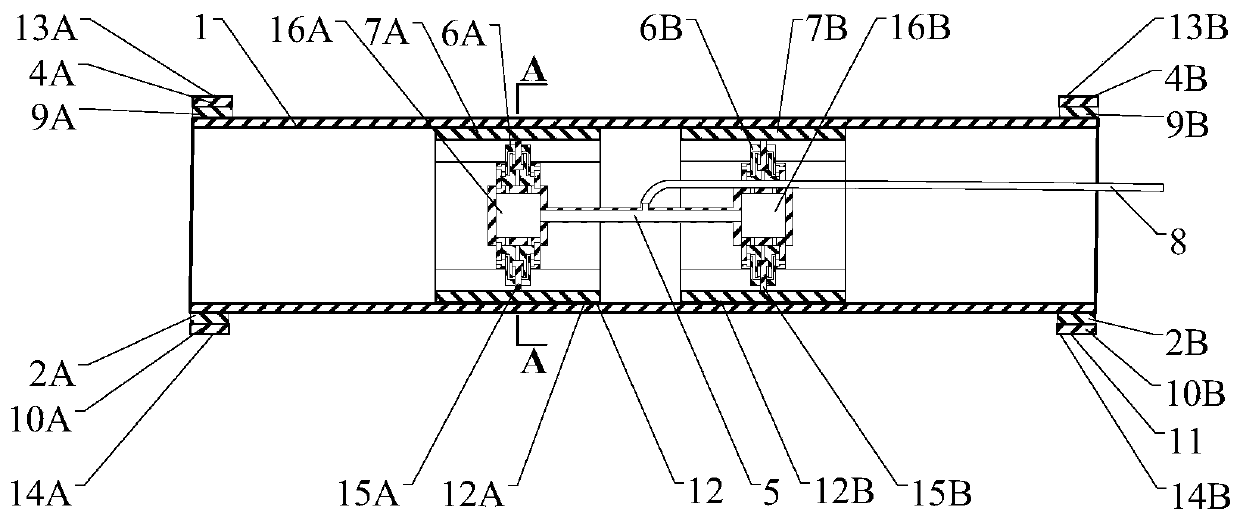

[0018] Such as Figure 1 to Figure 5 As shown, the bidirectional hydraulic expansion pipe fracture simulation experiment device includes: pipe support system 11, pipe expansion system 12, oil inlet pipe 8, and DIC test system 17; the side wall of the experimental pipe section 1 is provided with axial penetration prefabricated cracks 18. The prefabricated crack 18 is symmetrical about the axial middle plane of the test pipe section 1; the pipe support system 11 supports both ends of the test pipe section 1; The support system 12 provides hydraulic power; the pipeline expansion system 12 expands the experimental pipe section 1, and the prefabricated crack 18 expands bidirectionally; the DIC test system 17 observes the fracture process of the experimental pipe section 1 in real time.

[0019] The pipe support system 11 includes: upper left collar 13A, lower left collar 14A, upper right collar 13B, lower right collar 14B; The outer part is the upper left rubber ring 9A, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com