Card clothing for textile machine

A textile machine and card clothing technology, applied in textiles and papermaking, deburring devices, fiber processing, etc., can solve the problems of clogged and narrowed areas, impurity removal, and impurity wedges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

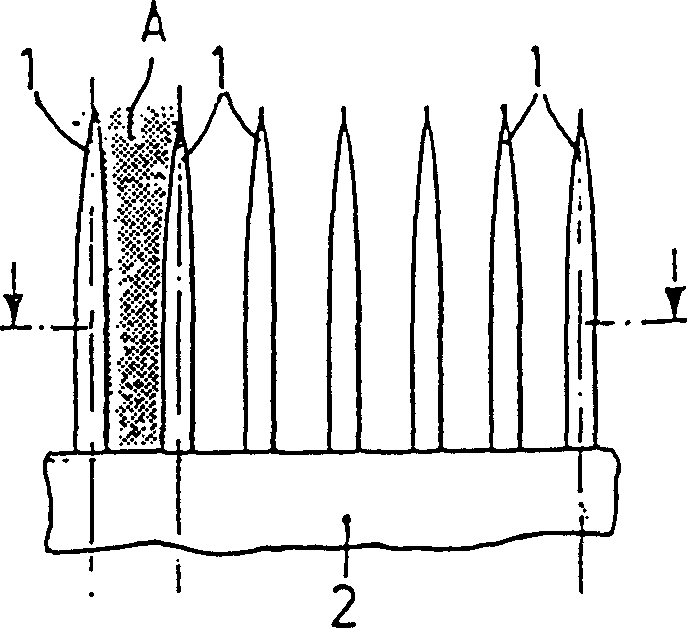

[0020] exist figure 1 In , a row of needles 1 is shown, which is fastened between two cover plates 2 while forming a needle strip.

[0021] The needles 1 are arranged between two cover plates 2, these needles are parallel to each other and have a certain distance apart, so just leave a free passage area A between every two needles 1, through this free passage, the comb to be combed bar in Figure 2 to Figure 6 Move in the direction of the arrow 3 drawn on it.

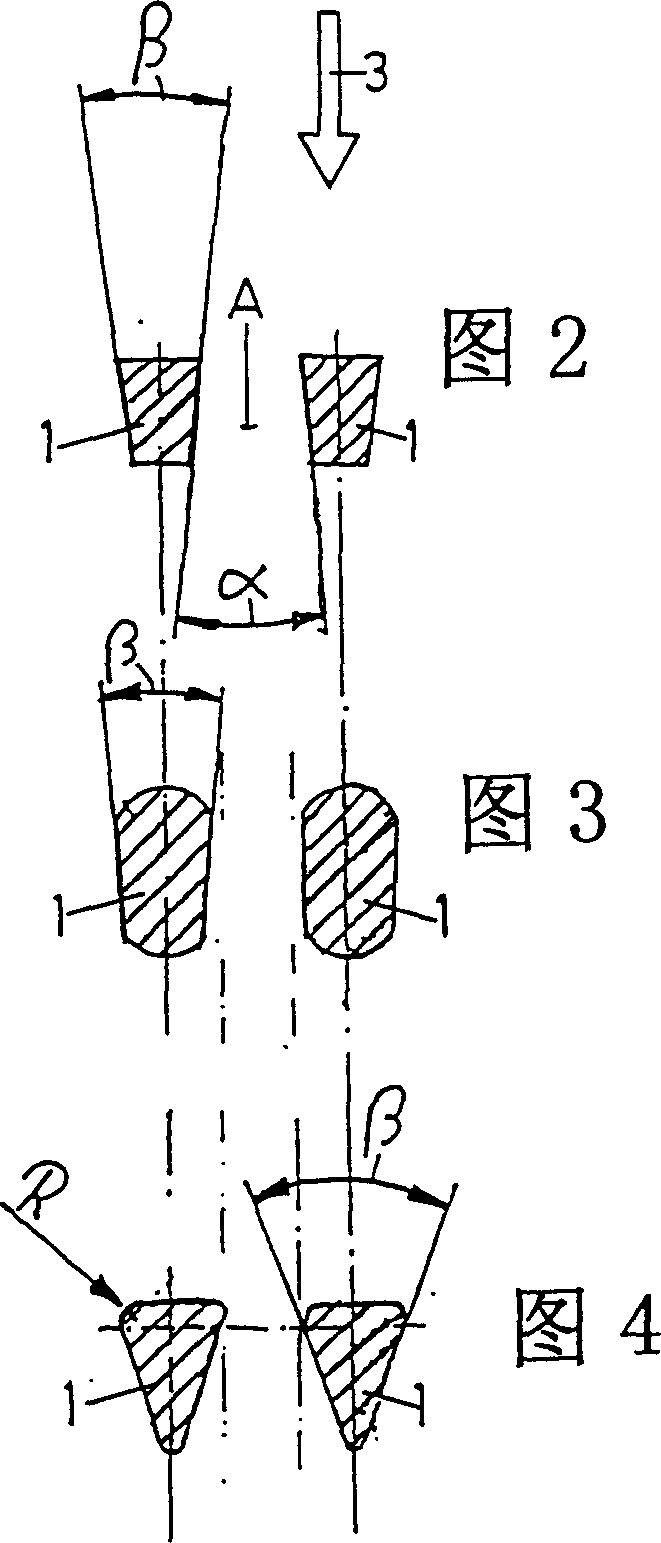

[0022] In the embodiment of FIG. 2 , the needles 1 have a completely trapezoidal cross-section, so that the free passage area A expands steadily at an angle α between the needles 1 in the direction of movement of the sliver (arrow 3 ).

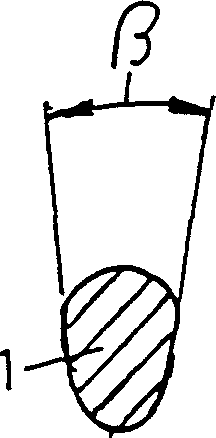

[0023] In the exemplary embodiment of FIG. 3 , the needles likewise have a trapezoidal basic shape, however, their ends are rounded and the needles taper accordingly at an angle β in the direction of movement (arrow 3 ).

[0024] In the embodiment of FIG. 4 , the cross-section of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com