Catalyst roasting - plastic dual-purpose rotary kiln

A phosphoric acid catalyst and roasting technology, which is applied in physical/chemical process catalysts, rotary drum furnaces, organic chemistry, etc., can solve the problems of large crushing loss, rising bed pressure drop, and easy crushing of particles, so as to improve the conversion rate of olefins, The effect of improving the operating life and improving the yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] The present invention is used in the dual-purpose rotary kiln (kiln body length 29m, interior warp r bs =φ2.0m) implementation. The kiln shell is tilted by 2.5%, and the inner wall of the shell has 120° folding boards, each piece is 0.4m long and (1 / 8) wide.r bs ; Set along the circumference of 24°, 15 pieces in each group; Adjacent lifting boards are staggered by 12°. The roasting kiln used is an external heating type, and the fuel is bituminous coal; it consists of a preheating section, a roasting section, and a cooling section; the inner wall of the kiln is equipped with a temperature measuring element to measure the temperature of each section.

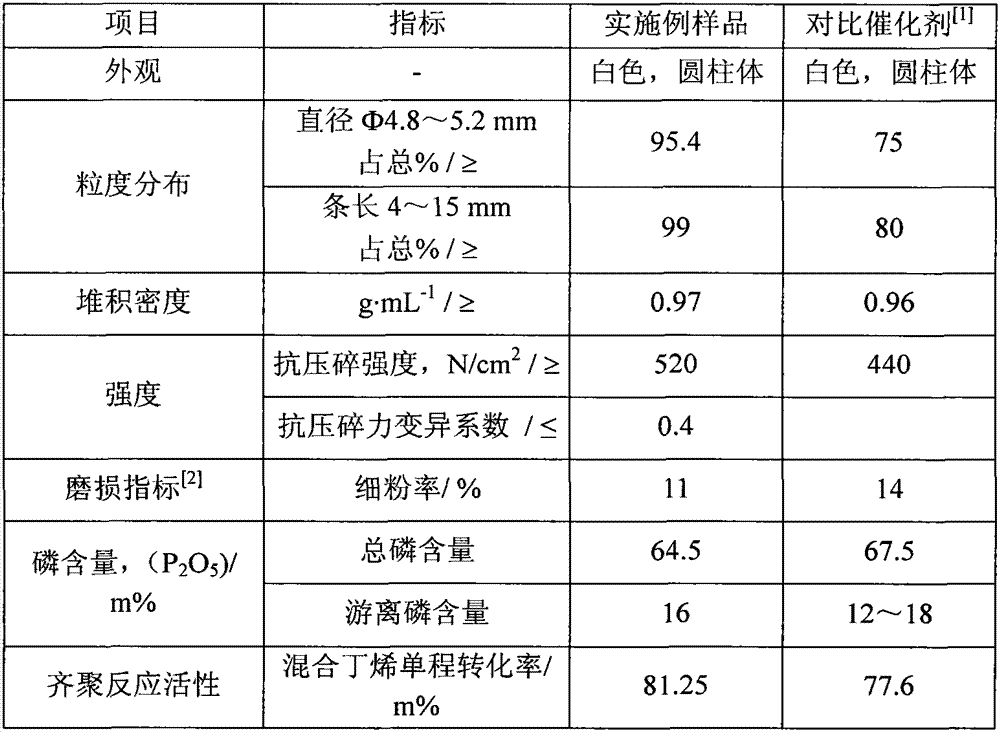

[0041] The precursor sent by the conveyor belt from the drying process is continuously added to the kiln body from the kiln head. The rotation speed of the kiln body is 0.25r / min. Heating and cooling, the total residence time of the material in the roasting kiln is 2.5h. The catalyst particles leaving the roasting kiln f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com