Method for measuring type II crack stress intensity factor threshold value of metal material

A stress intensity factor, metal material technology, used in the application of repetitive force/pulsation force to test the strength of materials, measuring devices, analyzing materials, etc., to achieve accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

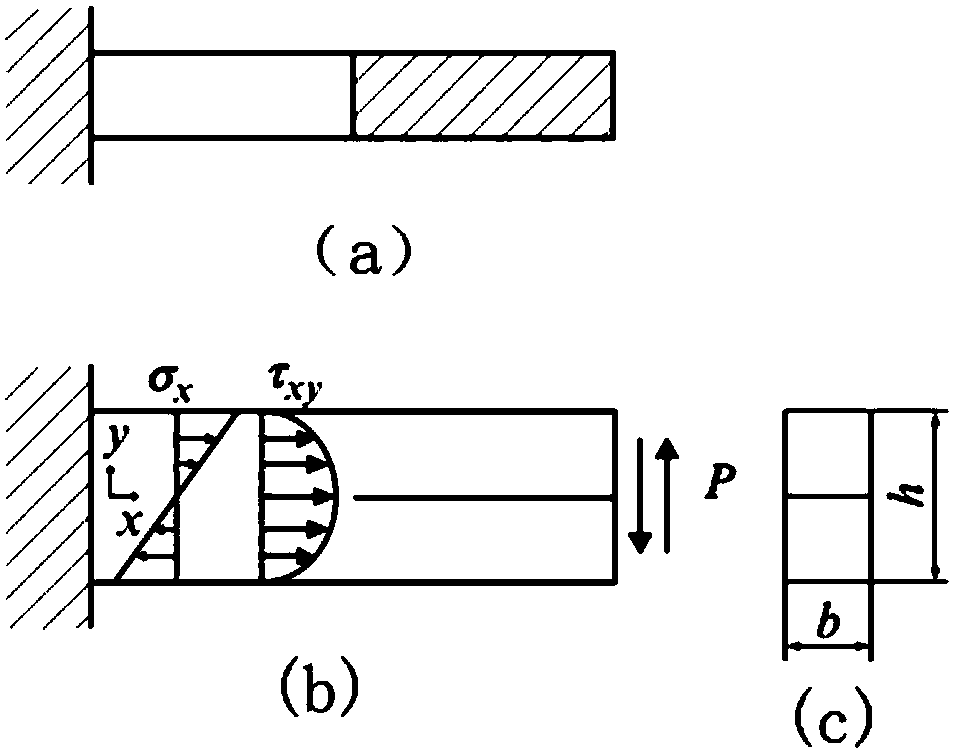

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The invention proposes a test method for the threshold value of the stress intensity factor of the type II crack. details as follows:

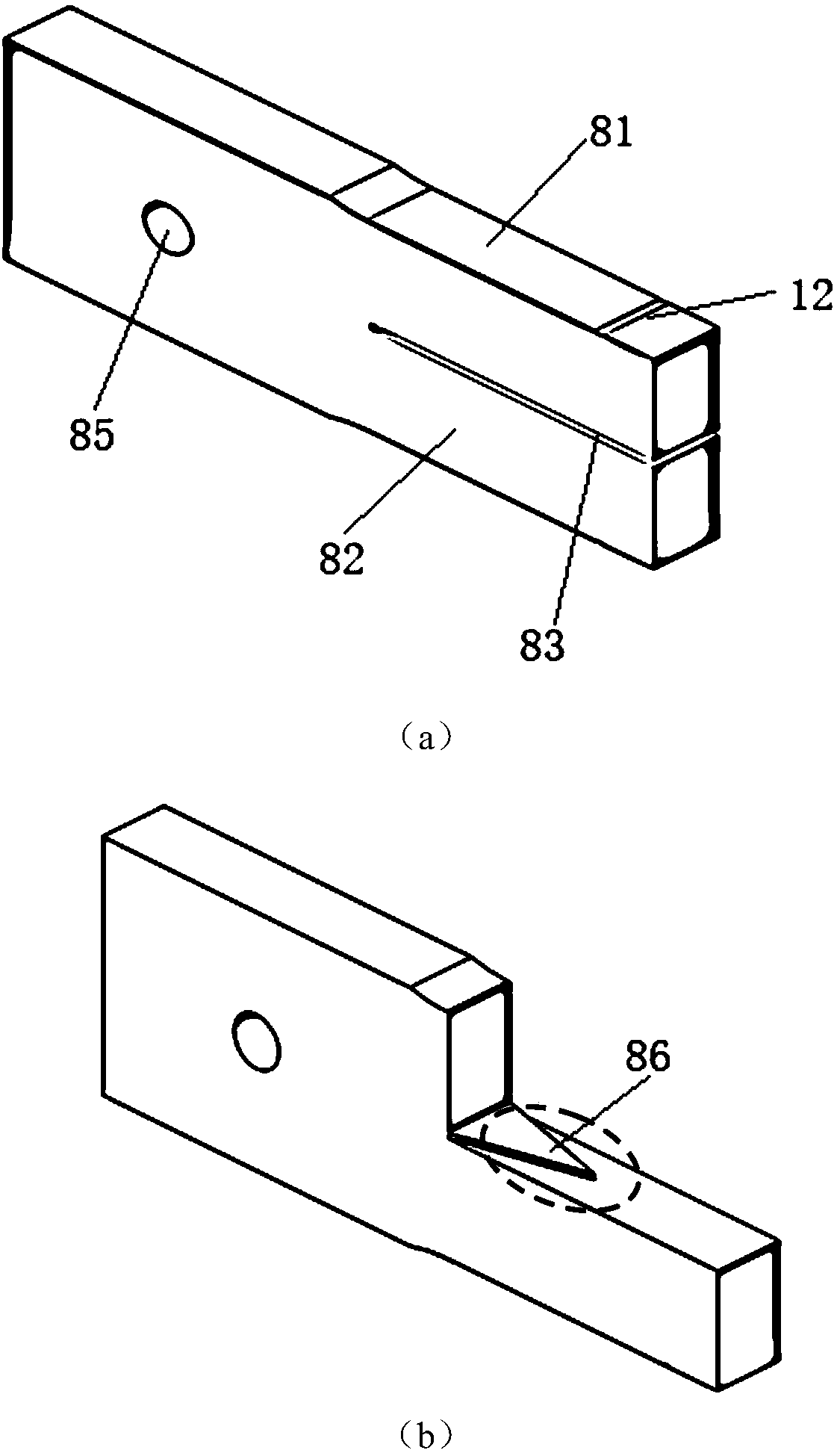

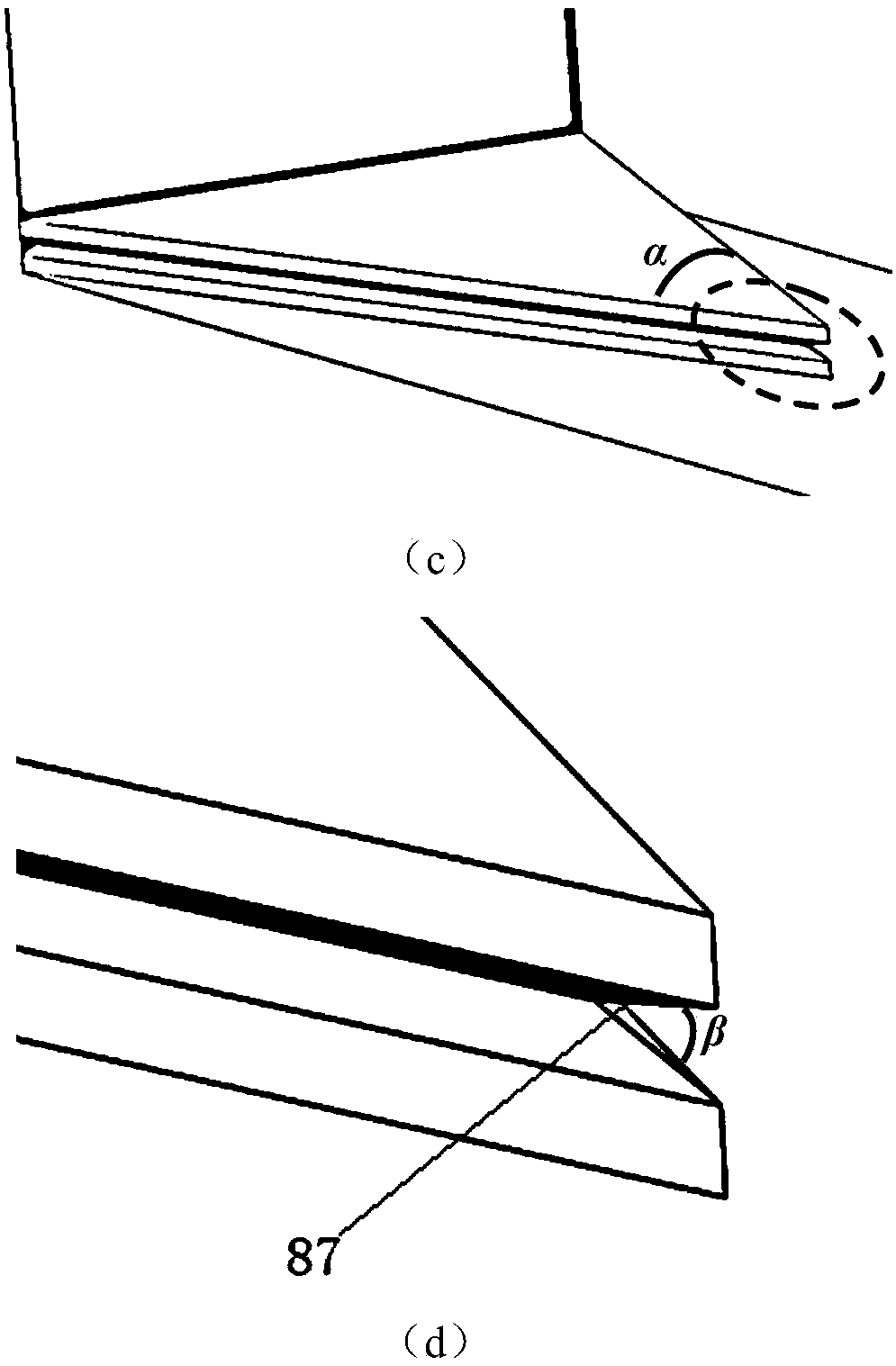

[0028] Sample design: such as figure 2 As shown, the sample 8 is in the shape of a cuboid, the left end is fixed by the sample fixing mechanism, and the right end is provided with a horizontal gap 83 extending from the right end to the center. There is a triangular crack initiation and expansion part 86 with the tip facing the right end face, and a V-shaped notch 87 is provided on the vertical edge at the tip, and the support rod 10 is inserted into the gap 83 .

[0029] Corresponding positions on the lower surface of the upper clamping part 1 , the upper surface of the upper cantilever 81 , the upper surface of the lower clamping part 2 and the lower surface of the lower cantilever 82 are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com