Large-scale composite material wind-power blade and preparation method thereof

A composite material and wind power blade technology, which is applied in wind power generation, wind turbine components, mechanical equipment, etc., can solve the problems of poor quality stability, long preparation period and high cost, reduce the emission of styrene gas, and solve the problem of infiltration performance. Poor, cost-avoiding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

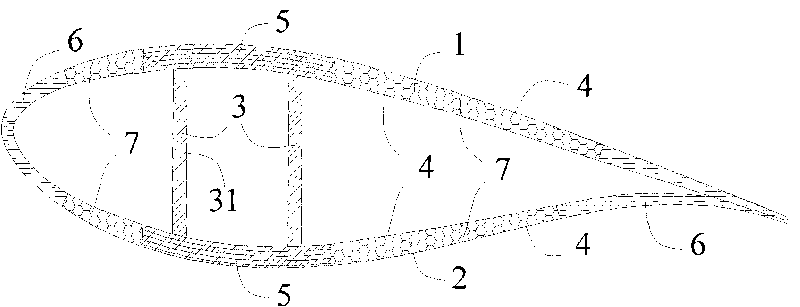

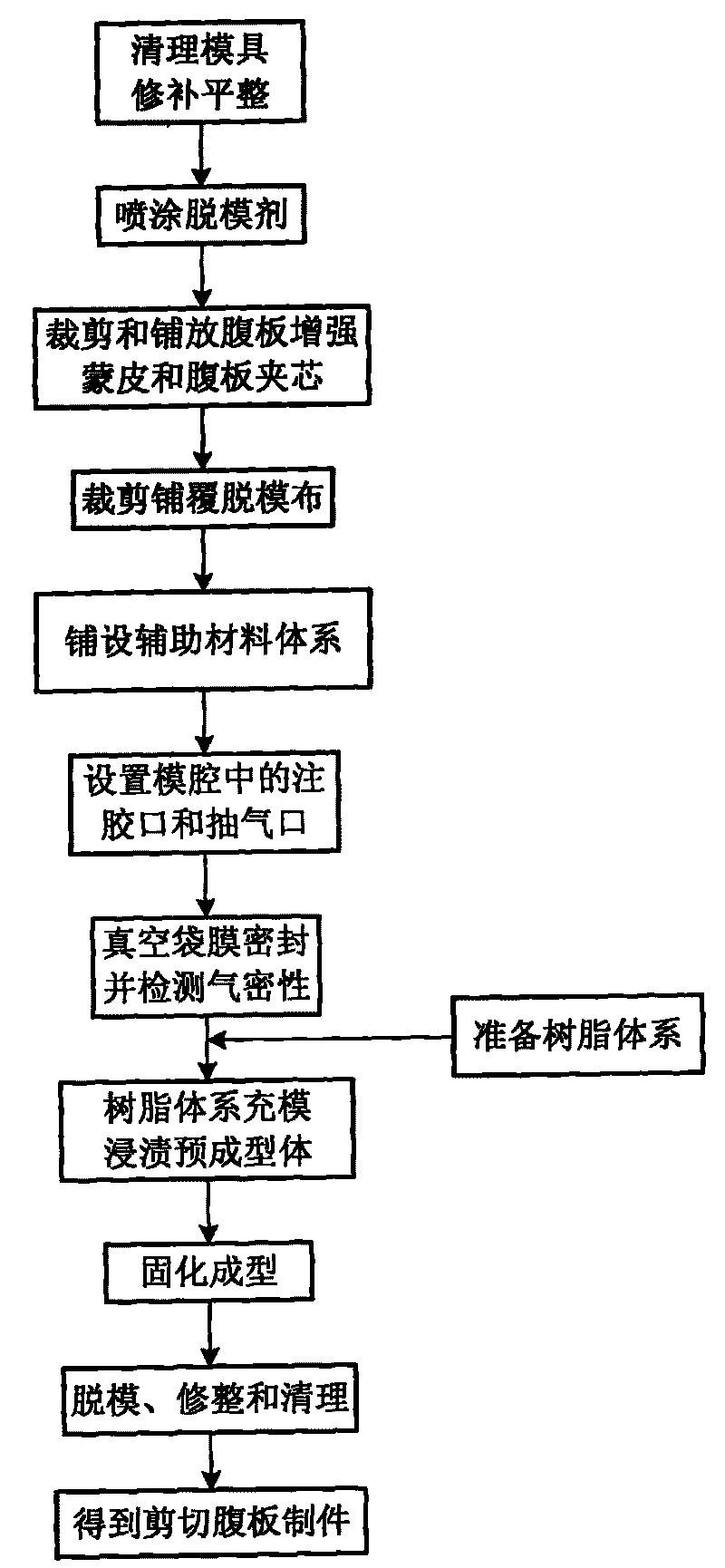

[0036] a kind of like figure 1 and figure 2 The large-scale composite material wind power blade of the present invention shown includes a suction side shell 1, a pressure side shell 2 and a shear web 3 fixed between the two shells, a suction side shell 1, a pressure side shell 2 Both are sandwich-type composite components with skin 4 covering the core material. The bases of the suction side shell 1 and the pressure side shell 2 are epoxy resin systems. The reinforcement material of the skin 4 is glass fiber. The core material includes The main load-bearing beam 5 of the blade, the flange reinforcement 6 at the edge of the blade for reinforcement, and the filling material 7 filled between the main load-bearing beam 5 and the flange reinforcement 6, the filling material 7 includes Balsa wood and PVC foam. Both the main bearing beam 5 and the flange reinforcement 6 are made of carbon fiber / glass fiber hybrid as reinforcement materials. The shear web 3 is also a sandwich stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com