Preparation method for crosslinkable high voltage-resistant high-energy density polyvinylidene fluoride (PVDF) plastic film

A polyvinylidene fluoride and plastic film technology, which is applied in the field of preparation of cross-linkable, high-voltage, high-energy-storage polyvinylidene fluoride plastic films, can solve problems such as difficulty in film drawing at low temperature, and achieves simple and controllable methods and low cost. Low, human and environmental friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment includes the following steps:

[0023] Step 1. Add poly(vinylidene fluoride-chlorotrifluoroethylene) P(VDF-CTFE) into the three-necked flask, the molar composition is VDF / CTFE=80:20, and add solvent at the same time, poly(vinylidene fluoride-trifluoroethylene) The mass ratio of chlorofluoroethylene) P(VDF-CTFE) to solvent is 3:100. After the poly(vinylidene fluoride-trifluorochloroethylene)P(VDF-CTFE) is fully dissolved, add the catalyst, and the catalyst and poly(vinylidene fluoride) Cl atom molar ratio is 1:1 in vinyl fluoride-trifluorochloroethylene) P (VDF-CTFE), and continues stirring reaction at 50 ℃ for 24 hours;

[0024] The solvent is N-methylpyrrolidone;

[0025] Described catalyzer is triethylamine;

[0026]Step 2, pour the solution finally obtained in step 1 into a beaker filled with hydrochloric acid of PH=3, the volume ratio of hydrochloric acid to the solution obtained in step 1 is 5:1, after stirring for 1 hour, the polymer is precipita...

Embodiment 2

[0033] This embodiment includes the following steps:

[0034] Step 1. Add poly(vinylidene fluoride-chlorotrifluoroethylene) P(VDF-CTFE) into the three-necked flask, the molar composition is VDF / CTFE=80:20, and add solvent at the same time, poly(vinylidene fluoride-trifluoroethylene) The mass ratio of chlorofluoroethylene) P(VDF-CTFE) to solvent is 3:100. After the poly(vinylidene fluoride-trifluorochloroethylene)P(VDF-CTFE) is fully dissolved, add the catalyst, and the catalyst and poly(vinylidene fluoride) Cl atom molar ratio is 1:1 in vinyl fluoride-trifluorochloroethylene) P (VDF-CTFE), and continues stirring reaction at 50 ℃ for 24 hours;

[0035] The solvent is N-methylpyrrolidone;

[0036] Described catalyzer is triethylamine;

[0037] Step 2, pour the solution finally obtained in step 1 into a beaker filled with hydrochloric acid of PH=3, the volume ratio of hydrochloric acid to the solution obtained in step 1 is 6:1, after stirring for 1 hour, the polymer is precipit...

Embodiment 3

[0043] This embodiment includes the following steps:

[0044] Step 1. Add poly(vinylidene fluoride-chlorotrifluoroethylene) P(VDF-CTFE) into the three-necked flask, the molar composition is VDF / CTFE=80:20, and add solvent at the same time, poly(vinylidene fluoride-trifluoroethylene) The mass ratio of chlorofluoroethylene) P(VDF-CTFE) to solvent is 3:100. After the poly(vinylidene fluoride-trifluorochloroethylene)P(VDF-CTFE) is fully dissolved, add the catalyst, and the catalyst and poly(vinylidene fluoride) Cl atom molar ratio is 1:1 in vinyl fluoride-trifluorochloroethylene) P (VDF-CTFE), and continues stirring reaction at 50 ℃ for 24 hours;

[0045] The solvent is N-methylpyrrolidone;

[0046] Described catalyzer is triethylamine;

[0047] Step 2, pour the solution finally obtained in step 1 into a beaker filled with hydrochloric acid of PH=3, the volume ratio of hydrochloric acid to the solution obtained in step 1 is 4:1, after stirring for 1 hour, the polymer is precipit...

PUM

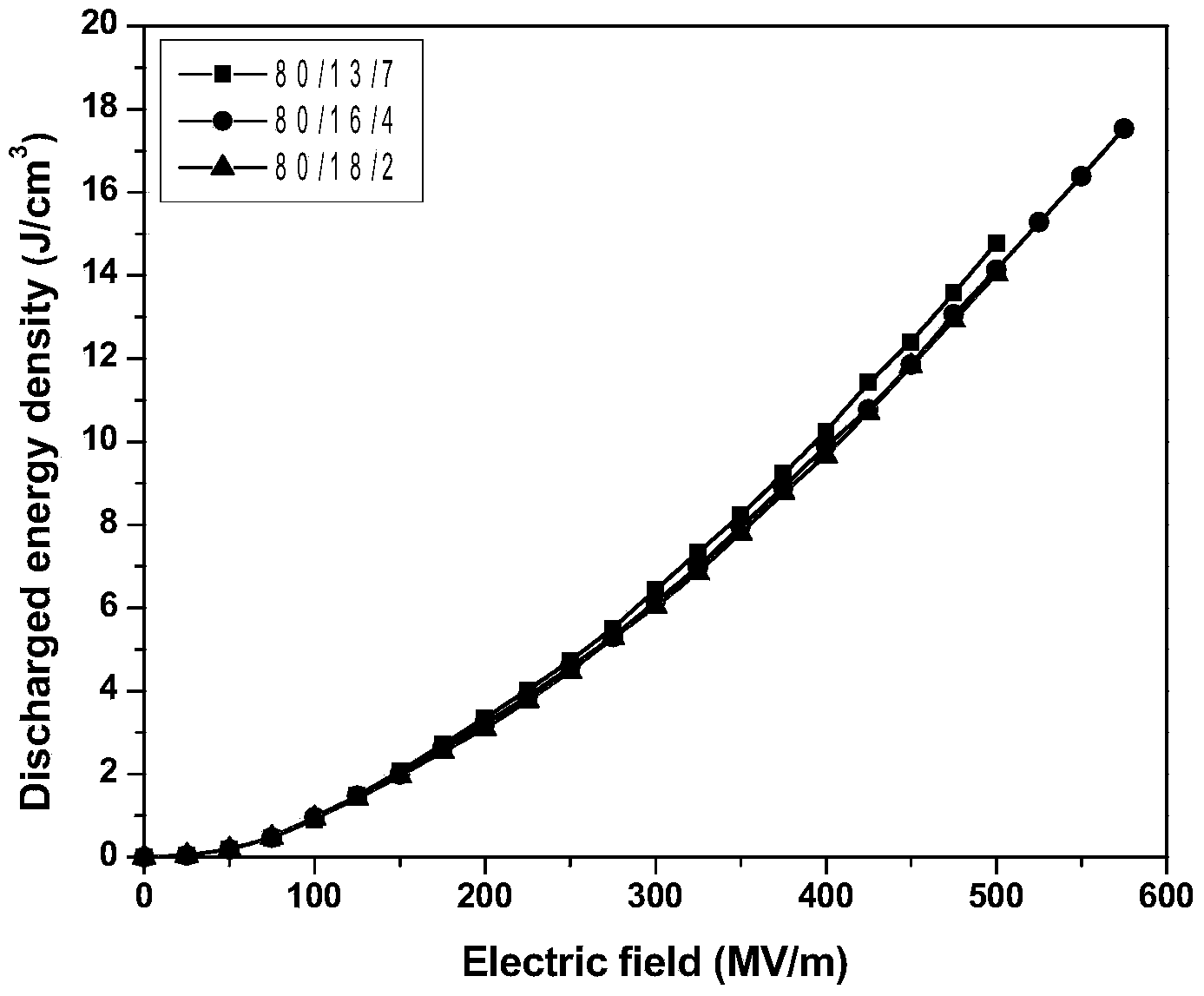

| Property | Measurement | Unit |

|---|---|---|

| Energy storage density | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com