Molybdenum and molybdenum alloy bar/tube high-temperature tensile detection device and method

A molybdenum alloy and equipment technology, applied in the field of mechanical performance testing of metal materials, can solve the problems of limited testing conditions, reduce the reliability of test results, increase testing costs and test cycles, etc., to prevent oxidation reactions and increase tensile testing temperature area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

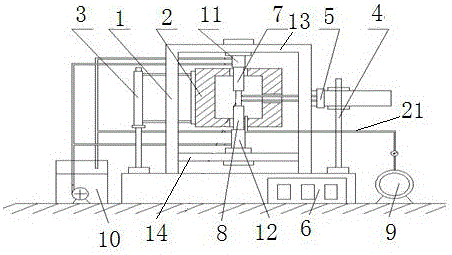

[0039] Example 1: High temperature tensile property test of molybdenum alloy rods at 1200°C

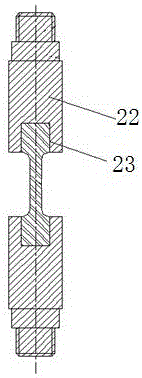

[0040] First, mark the original gauge length on the surface of the molybdenum alloy bar standard sample, measure the original gauge length L and the cross-sectional diameter D of the standard sample with a measuring tool, calculate the original cross-sectional area S, and then uniformly Apply graphite emulsion, screw both ends of the sample into the internal thread area of the bar special fixture, the external thread area is also evenly coated with graphite emulsion and connected to the internal thread area of the connecting pipe, open the high temperature furnace, turn the rotating bracket, Keep the bar tensile sample and the special fixture for the bar in the center of the high-temperature furnace body, and then insert 3 thermocouples at both ends and the center of the bar sample to control the temperature of the upper, middle and lower parts of the bar sample , and then fix the...

Embodiment 2

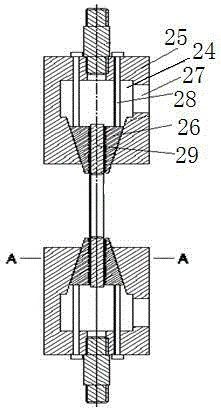

[0044] Example 2: High temperature tensile performance test of molybdenum alloy pipe at 1200°C

[0045] The construction of the test platform, the process of the tensile test and the calculation of the test data in the high-temperature tensile performance test of the molybdenum alloy pipe can refer to Example 1 for the test. The test calculation results are shown in Table 2.

[0046] Table 2 Tensile test results of molybdenum alloy pipes at 1200℃

[0047]

[0048] It can be seen from Table 2 that in the tensile test of molybdenum alloy pipes at 1200 °C, the pipe samples were evenly stressed, and there were no abnormalities such as stretching and cracking. The mechanical performance data of the test were stable and accurate, and the selected fixture structure and materials were reliable. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com