Temperature measurement method for electrified tensile test piece and tensile test device

A technology for tensile testing and temperature measurement, which is applied in the direction of measuring devices, preparation of test samples, and application of stable tension/pressure to test material strength, etc., to achieve accurate temperature measurement, convenient fixation, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

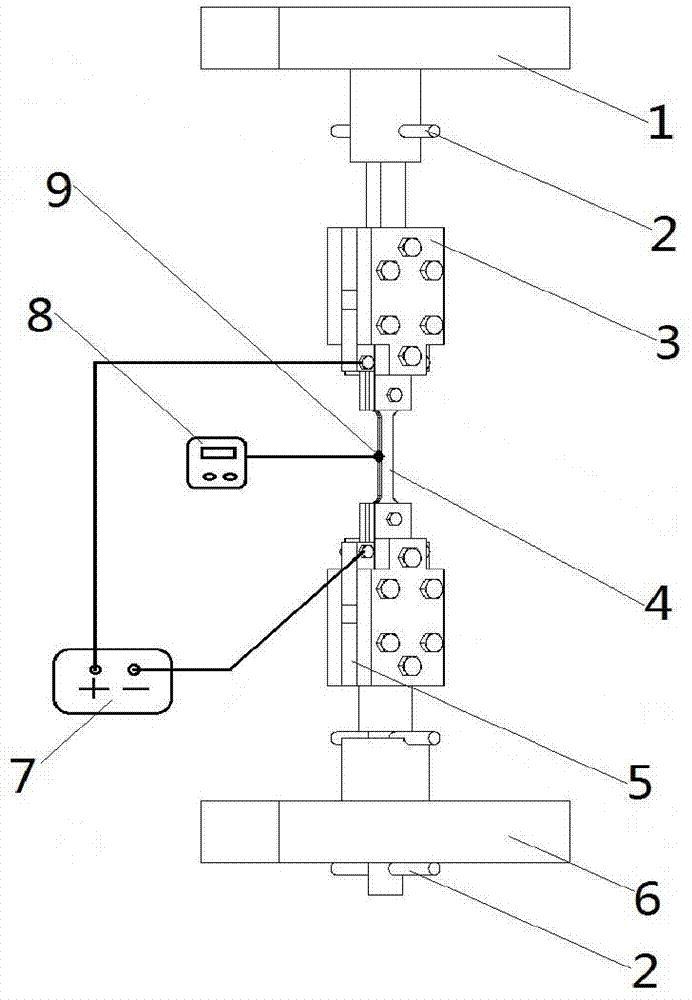

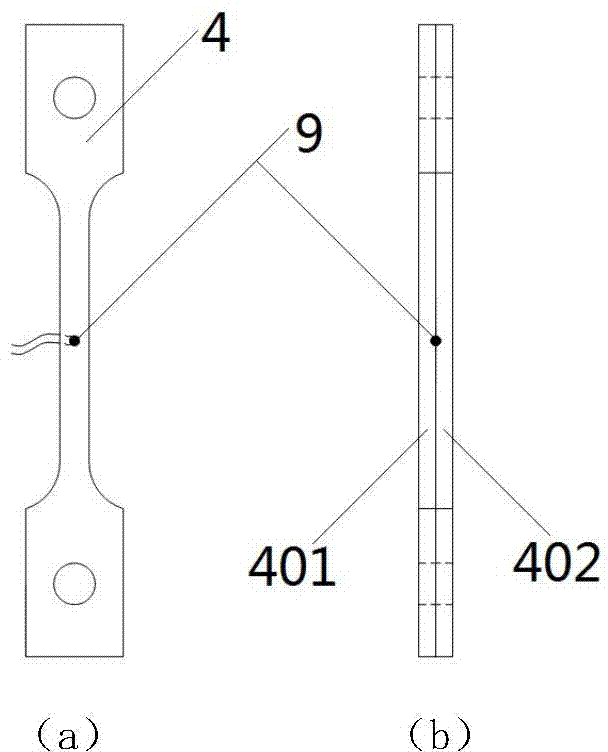

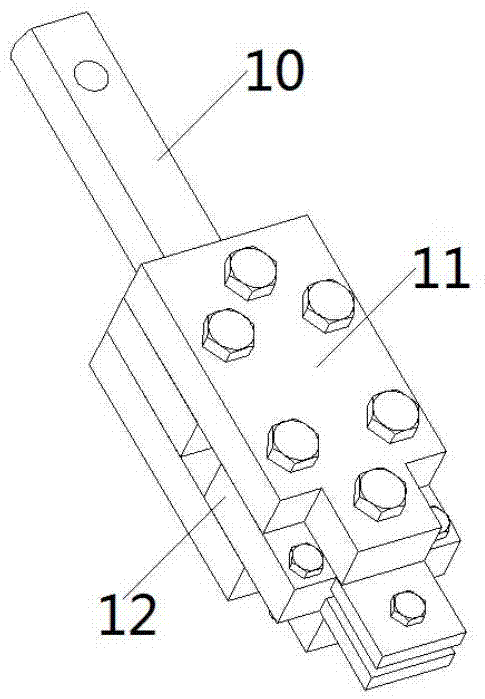

[0024] This embodiment is a temperature measurement method and a tensile test device for an energized tensile test piece. The electronic universal testing machine with an insulating chuck is used to complete the energized unidirectional tensile test and the test piece of a metal material test piece through the cooperation of a thermocouple. Real-time measurement of temperature. Firstly, anti-oxidation treatment is carried out on the metal material test piece, and the anti-oxidation protective agent is evenly sprayed on the surface of the two test pieces. After the surface protective coating is naturally dried at room temperature, the test piece is clamped by the chuck of the testing machine; then , insulate the thermocouple, mix the high-temperature resistant inorganic insulating glue evenly according to the requirements of use, apply a layer of insulating glue on the thermocouple, and cure according to the curing conditions of the high-temperature inorganic insulating glue, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com