Automatic feeding device of drop-hammer type impact testing machine

An impact testing machine and automatic feeding technology, applied in the direction of testing material strength, conveyor, transportation and packaging using one impact force, can solve the problems of waste of resources, low work efficiency, high labor intensity of operation, etc., and achieve convenient operation and use. , high work efficiency, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

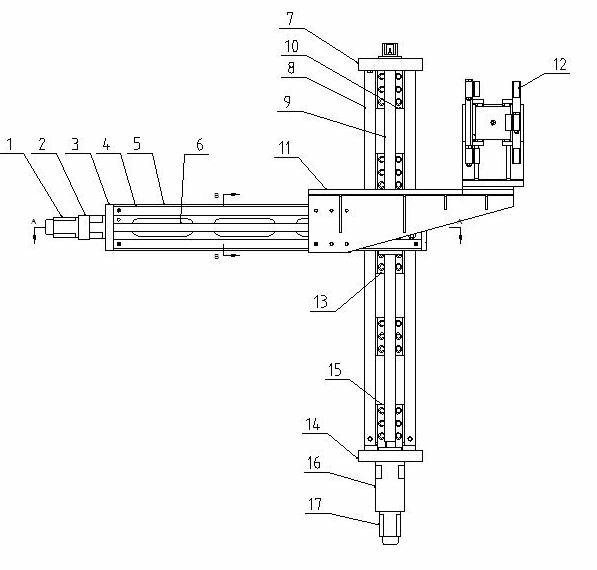

[0016] An automatic feeding device for a drop weight impact testing machine, which includes a transmission mechanism and a sample holder 12. The transmission mechanism includes two parts of lifting transmission and horizontal transmission.

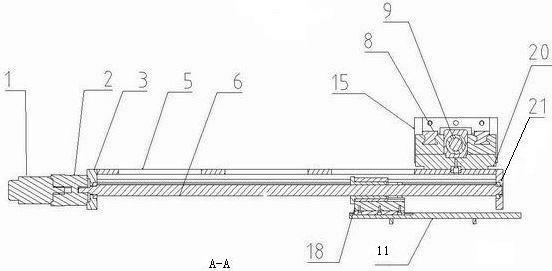

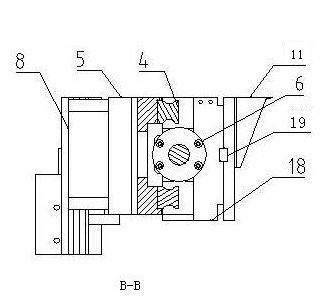

[0017] From figure 1 , figure 2 It can be seen from the figure that the lifting transmission part in the transmission mechanism includes the lifting guide rail pair 8, the lifting ball screw pair 9, the lifting connecting bracket 20, the lifting servo motor 17, etc., and the lifting guide rail pair 8 passes through the connecting base 15, the connecting base The seat 10 and the intermediate connection base 13 etc. are fixed on the column of the testing machine, the connection base 10 and the connection base 15 at the upper and lower ends of the lifting guide rail pair 8 are respectively provided with an upper end plate 7 and a lower end plate 14, and the lifting ball screw pair 9 Corresponding to the lifting guide rail pair 8, it is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com