Method for measuring combination strength of aluminum film of film aluminum steel composite board and steel substrate

A combination strength and composite plate technology, which is applied in the direction of measuring devices, test sample preparation, instruments, etc., can solve the problems of difficult direct and accurate measurement of the bonding strength of thin-film aluminum-steel composite plate aluminum film and steel matrix, and achieve brazing The effect of low temperature and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

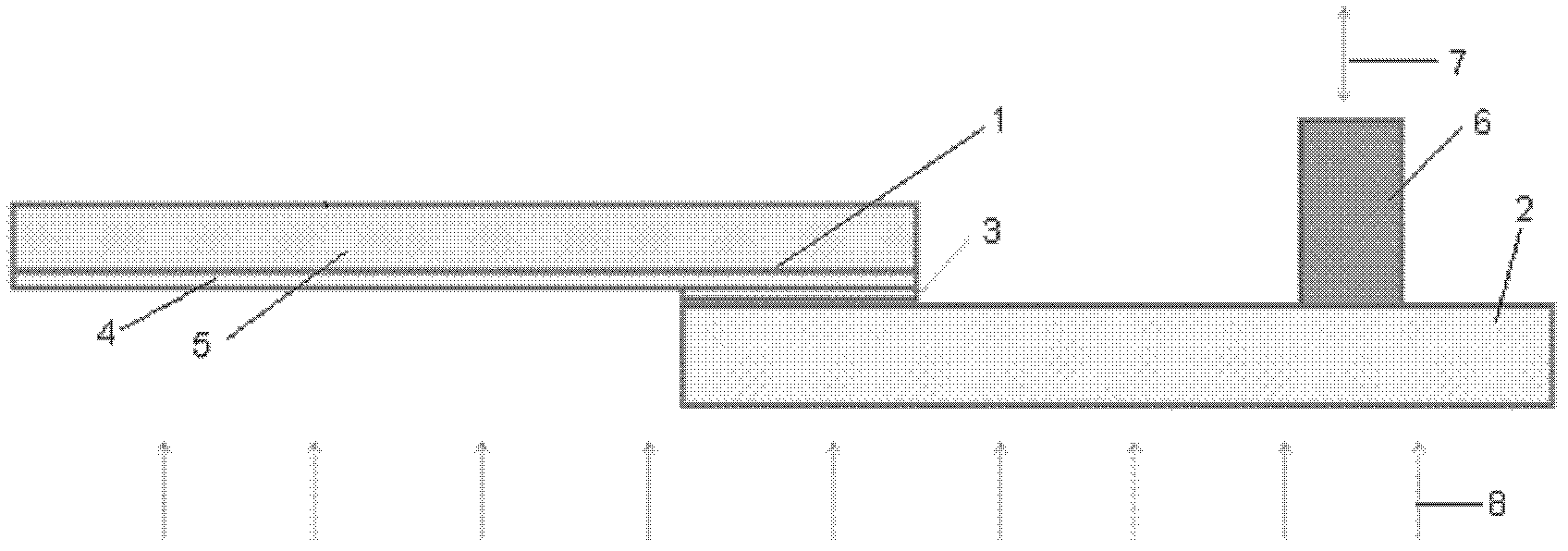

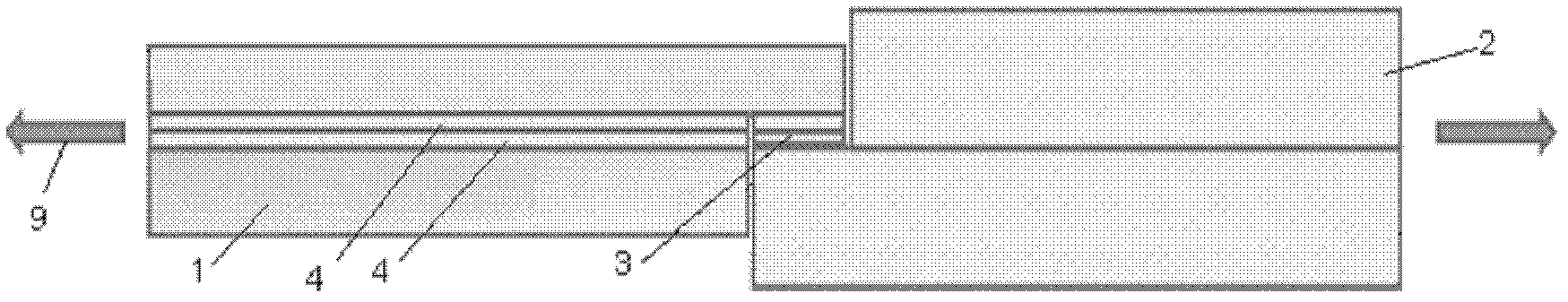

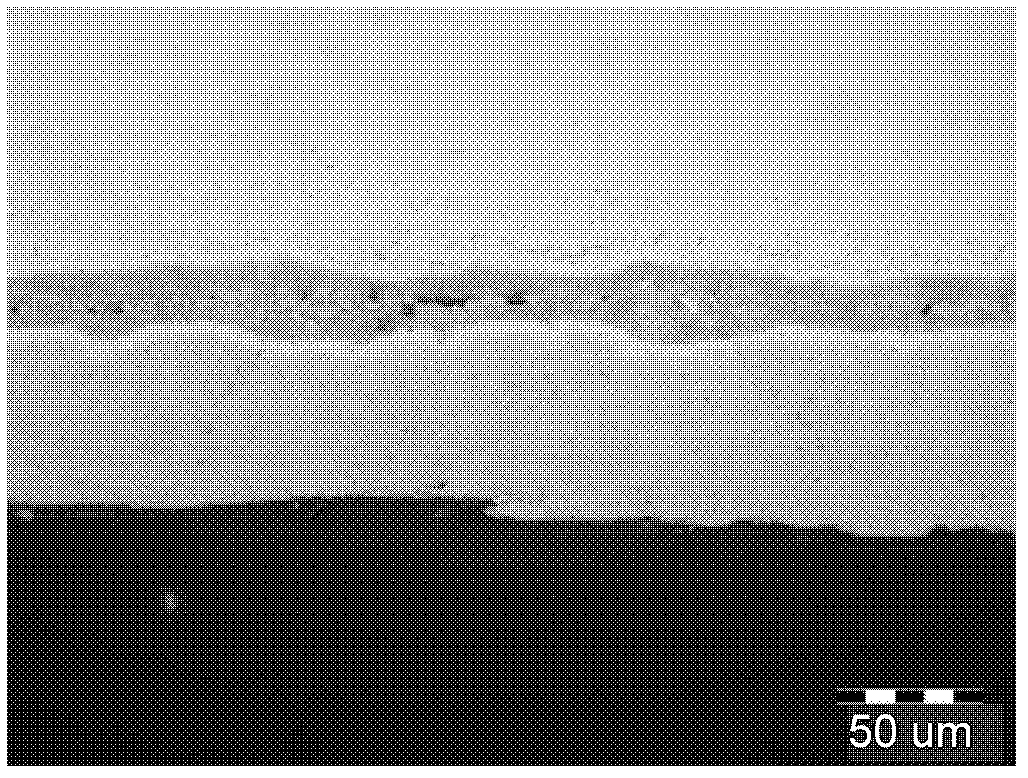

[0019] Specific embodiment one: a method for measuring the bonding strength of the thin-film aluminum-steel composite plate aluminum film and the steel matrix in this embodiment is carried out in accordance with the following steps: 1. Grinding the surface to be welded of the thin-film aluminum-steel composite plate and the aluminum alloy , polishing, and then clean the thin-film aluminum-steel composite board, the surface to be welded of aluminum alloy and the zinc-aluminum solder for use; 2. The thin-film aluminum-steel composite board and aluminum alloy obtained in step 1 are bonded on one side by zinc-aluminum solder Connect and prepare for welding; 3. Welding: heat the thin-film aluminum-steel composite plate, zinc-aluminum brazing material, and aluminum alloy overlapped in step 2 to 50 ° C ~ 550 ° C, and then place the ultrasonic head on the surface of the aluminum alloy for ultrasonic After processing for 0.5-20s, after the ultrasonic application is completed, the ultras...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that the zinc-aluminum solder in step 1 has a thickness of 0.1-10 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment 3: This embodiment differs from specific embodiments 1 to 2 in that the single-sided lap joint described in step 2 has a length of 2 mm to 10 mm. Others are the same as the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com