Rigid alloy soldered joint shearing property testing device

A technology of brazed joints and hard alloys, applied in the direction of using stable shear force to test the strength of materials, etc., can solve the problems of inability to accurately test the strength of brazed joints, achieve efficient and reliable testing methods, ensure test quality, and process convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

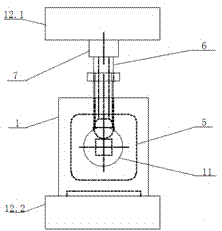

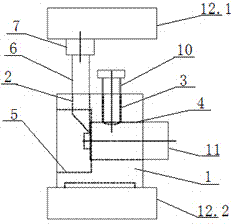

[0017] like Figure 1 to Figure 4 As shown, the present invention is used for rod-shaped brazing samples ( Figure 5 ) The composition and structure of the shear performance testing device are as follows:

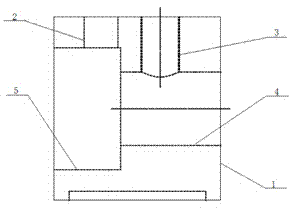

[0018] The cemented carbide brazed joint shear performance testing device uses a tetragonal structure as the base 1, and a light hole 4 for placing the sample is designed and processed on one side. The light hole can be circular or square or other shapes. Design a vertical round hole with a threaded hole 3 in the light hole 4 for fixing the bolt 10, and design a square groove 5 on the other side for taking out the sample. The square groove 5 communicates with the light hole 4, and the axis of symmetry coincides. A smooth hole 2 is designed on the upper surface of the square groove 5. The smooth hole 2 can be circular or square, and is mainly used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com