Device and method for intelligently measuring joint bending angles of welding and connection of dissimilar materials

A technology of intelligent measurement and dissimilar materials, applied in the direction of applying stable bending force to test the strength of materials, etc., can solve the problems of inability to directly and dynamically measure the bending angle, precise control of test progress, and influence of test results, etc., to reduce Occupies space, saves time, and improves measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] The composition and structure of the dissimilar material welding bending performance testing device used in the present invention are as follows:

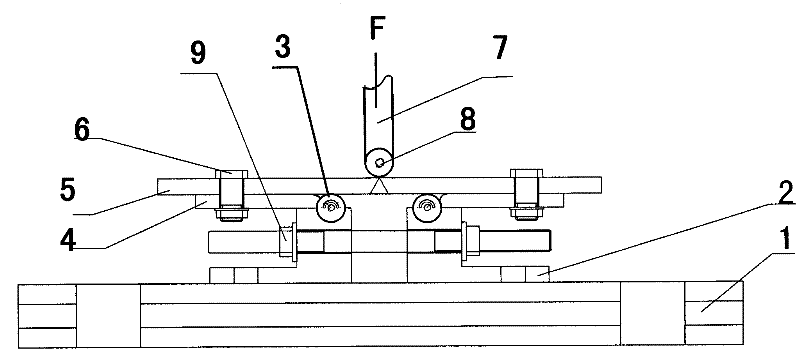

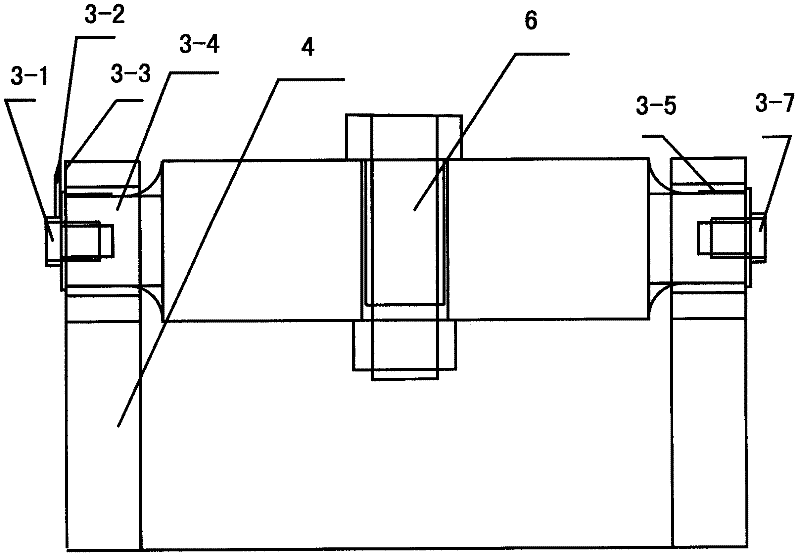

[0033] Such as figure 1 As shown, two rollers 2 symmetrically arranged on the left and right are fixed on the guide rail base 1, and a roller positioning shaft 9 is provided in the middle of the two rollers to prevent the span of the two rollers from changing during the bending test. The upper end of the supporting roller 2 is a bending angle measuring device 3, wherein the bending angle measuring device is composed of six parts, that is, the supporting roller 2 is equipped with a high-load bearing 3-4, and the inner core of the bearing is fixedly connected with the high-precision precision pointer 3-2. The outer ring of the bearing is fixedly inlaid with a dial 3-3, and the outer ring of the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com