Device and method for testing bending property of joint for welding and connecting dissimilar materials

A testing device and bending performance technology, which is applied in the direction of applying a stable bending force to test the strength of materials, etc., can solve the problem that the weld centerline cannot always be on the same vertical plane as the indenter, which increases economic costs and requires a large space and other issues to achieve the effect of reducing occupied space, saving time, and reducing the area occupied by equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

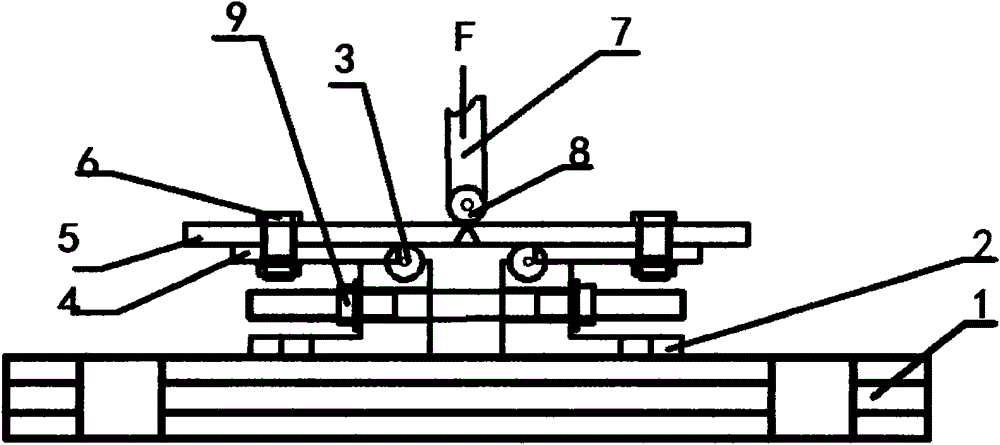

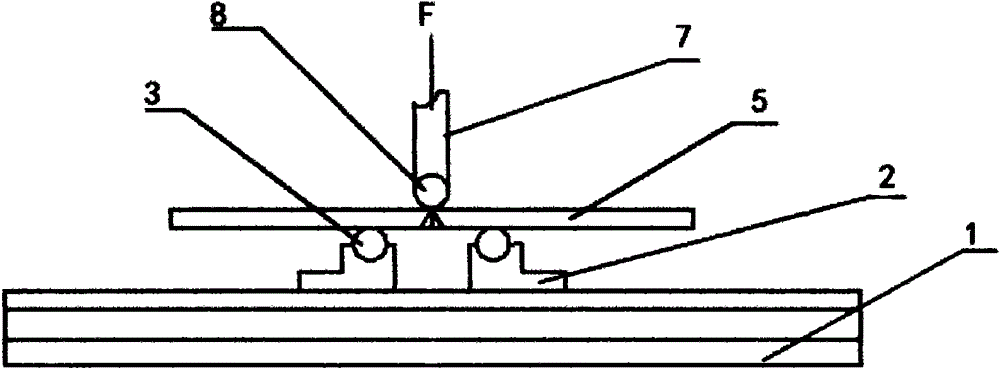

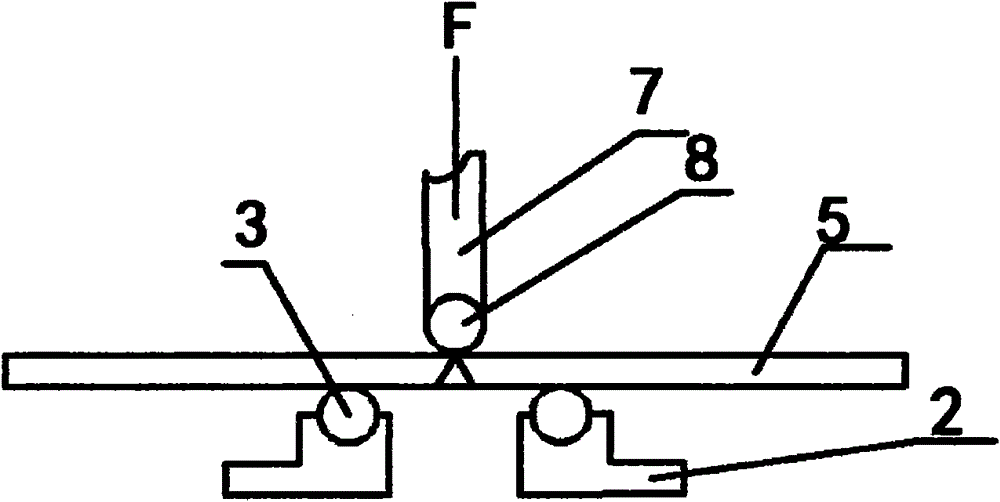

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] The composition and structure of the dissimilar material welding bending performance testing device used in the present invention are as follows:

[0033] Such as figure 1 As shown, two rollers 2 symmetrically arranged on the left and right are fixed on the guide rail base 1, and base fixing bolts and roller fixing bolts are distributed on the base below the rollers. A roller positioning shaft 9 is arranged in the middle of the two rollers to prevent the span of the two rollers from changing when doing the bending test. The upper end surface of the supporting roller is a cylinder 3, and the upper end of the supporting roller is connected with the left and right symmetrical two dynamic synchronous fixed wing plates 4 through the cylinder, and the specimen fastening bolts 6 are installed on the two dynamic synchronous fixed wing plates 4 at the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com