Method for measuring bond strength between high-intensity glass fiber rib and concrete

A glass fiber reinforcement and bonding strength technology, which is applied in the field of measuring the bonding strength between high-strength glass fiber reinforcement and concrete, can solve the problems of single test method, test failure, GFRP tendon pinching, etc., and achieve simple test method, low cost, Wide range of effects

Active Publication Date: 2010-09-01

CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

View PDF0 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, although the research on the bond strength of GFRP bars (GFRP is the English abbreviation of glass fiber) at home and abroad has achieved certain results, there are still some problems. For example, most of the bond tests at home and abroad are pull-out tests. , the test method is single, and the test failure often occurs. The main reason is that if the protruding GFRP tendon is too long, when the pull-out test is performed, the protruding GFRP tendon will first produce elastic deformation, thus affecting the accuracy of the test results. ; In addition, if the GFRP tendon is particularly tightly bonded to the concrete, the clamping force of the chuck needs to be increased to clamp the protruding GFRP tendon. At this time, the protruding GFRP tendon is easily crushed, resulting in the failure of the test. Therefore, Existing test methods, the test results obtained have relatively large limitations, and it is difficult to test successfully

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

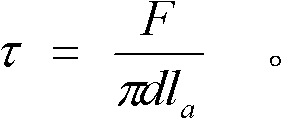

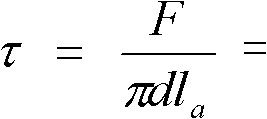

The invention provides a method for measuring bond strength between a high-intensity glass fiber rib and concrete, which comprises the following steps of: A, pouring test pieces: inserting the high-intensity glass fiber rib into a PVC plastic sleeve in a cubic pouring mold, wherein the lower end of the high-intensity glass fiber rib is positioned in the cubic pouring mold, and the top of the high-intensity glass fiber rib extends out of the cubic pouring mold; B, performing the loading process: after curing the test pieces in a curing chamber to the age, taking the test pieces out for testing, and performing the test on a hydraulic universal testing machine; and C: calculating the bond strength: calculating a bond strength value tau between the high-intensity glass fiber rib and the concrete by the following formula. The measured result obtained by the method can more accurately reflect the bond strength between the high-intensity glass fiber rib and the concrete, and the method for measuring the bond strength between the high-intensity glass fiber rib and concrete has the advantages of simpleness and low cost.

Description

technical field The invention belongs to the technical field of civil engineering and relates to a method for measuring the bonding strength of high-strength glass fiber bars and concrete. technical background At present, although the research on the bond strength of GFRP bars (GFRP is the English abbreviation of glass fiber) at home and abroad has achieved certain results, there are still some problems. For example, most of the bond tests at home and abroad are pull-out tests. , the test method is single, and the test failure often occurs. The main reason is that if the protruding GFRP tendon is too long, when the pull-out test is performed, the protruding GFRP tendon will first produce elastic deformation, thus affecting the accuracy of the test results. ; In addition, if the GFRP tendon is particularly tightly bonded to the concrete, the clamping force of the chuck needs to be increased to clamp the protruding GFRP tendon. At this time, the protruding GFRP tendon is easil...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N19/04

Inventor 刘朝晖秦仁杰李盛赵锋军周科峰华振良万兵

Owner CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com