Testing device for two-way loading test of material

A test device and two-way loading technology, which is applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems of high cost, complex structure of test equipment, limitations, etc., and achieve the effect of simple equipment structure, convenient loading ratio, and reduced test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

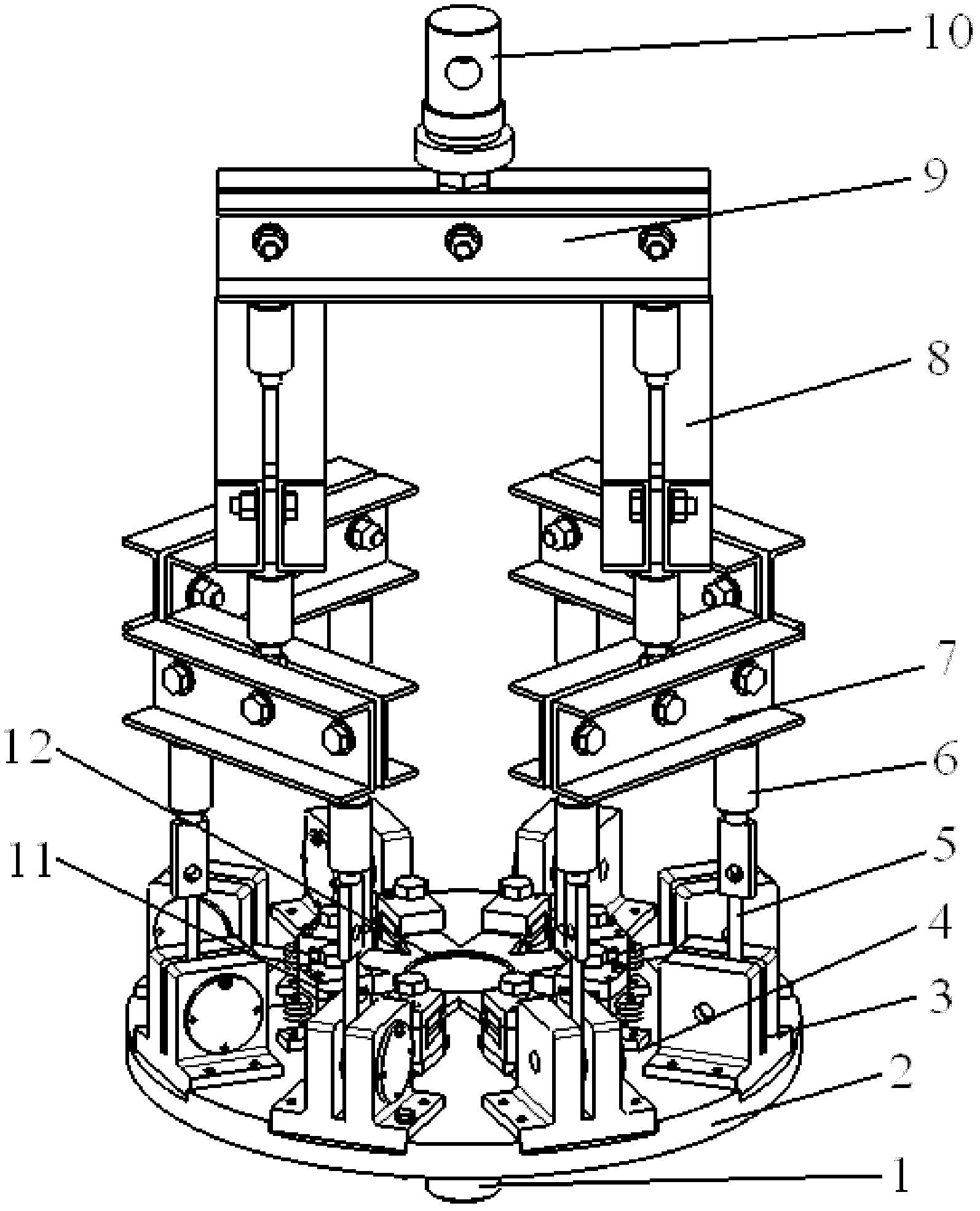

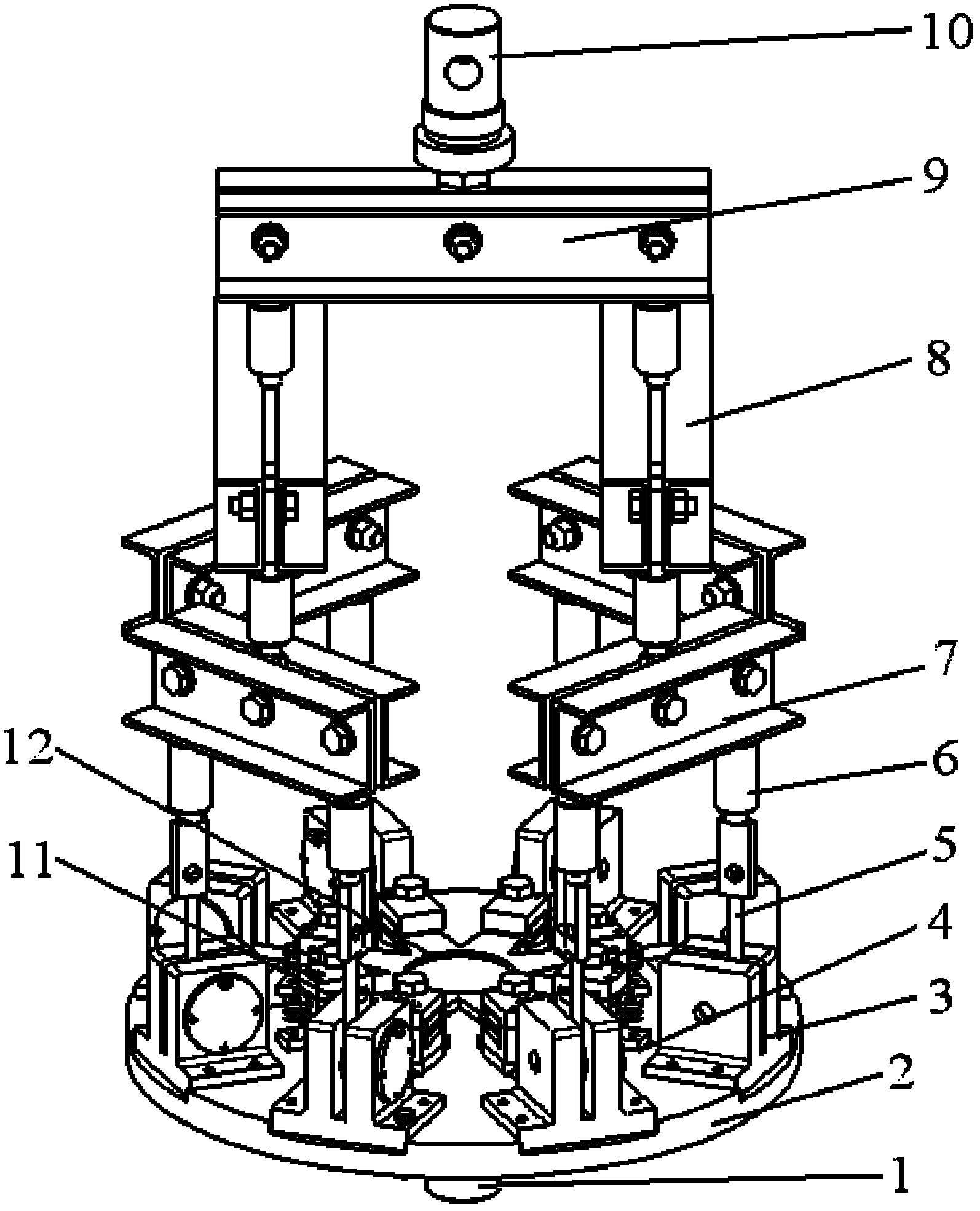

[0030] A test device for bidirectional loading test of materials, its structure is as follows figure 1 Shown, be made of base, lever structure, chuck 11 three parts, base is located at the bottom, and lever structure and chuck 11 are all installed on the base.

[0031] Among them, the bottom connector 1, the chassis 2, the pulley 3 and the slide rail 4 constitute the base; the steel wire 5, the turnbuckle 6, the first level lever 7, the second level lever 8, the third level lever 9 and the top connector 10 A lever structure is formed; the chuck 11 is installed on the slide rail 4 .

[0032] Pulley 3 is provided with 8, is evenly installed on the outer circumference of chassis 2, and slide rail 4 is connected with pulley 3, and bottom connector 1 is arranged on the center of bottom of chassis 2, and bottom connector 1 can connect universal testing machine. The first-level lever 7, the second-level lever 8, and the third-level lever 9 are connected from bottom to top through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com