Test device for light steel frame beam column node bearing test

A beam-column joint and test device technology, applied in the field of construction engineering, can solve the problems of inconvenient replacement, high cost, large space occupation, etc., and achieve the effects of low cost, simple loading, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific embodiments.

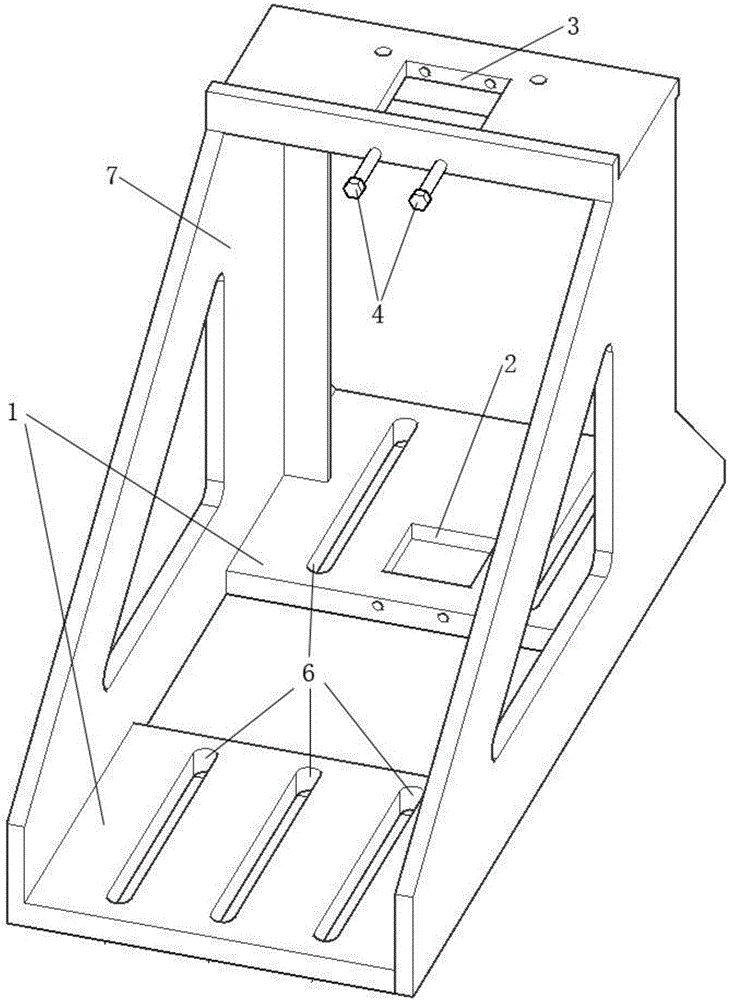

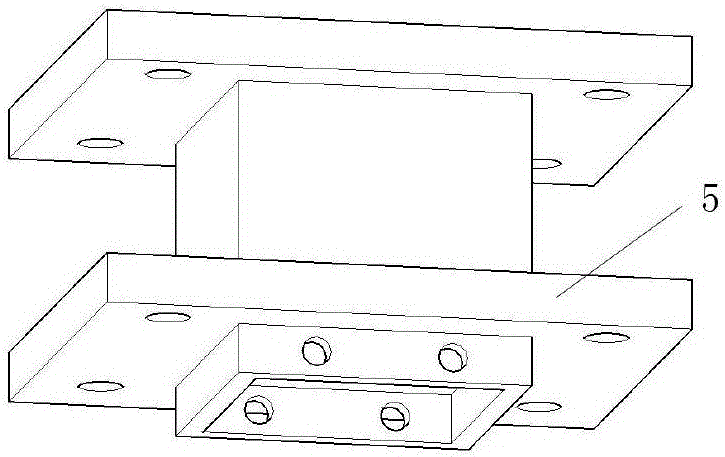

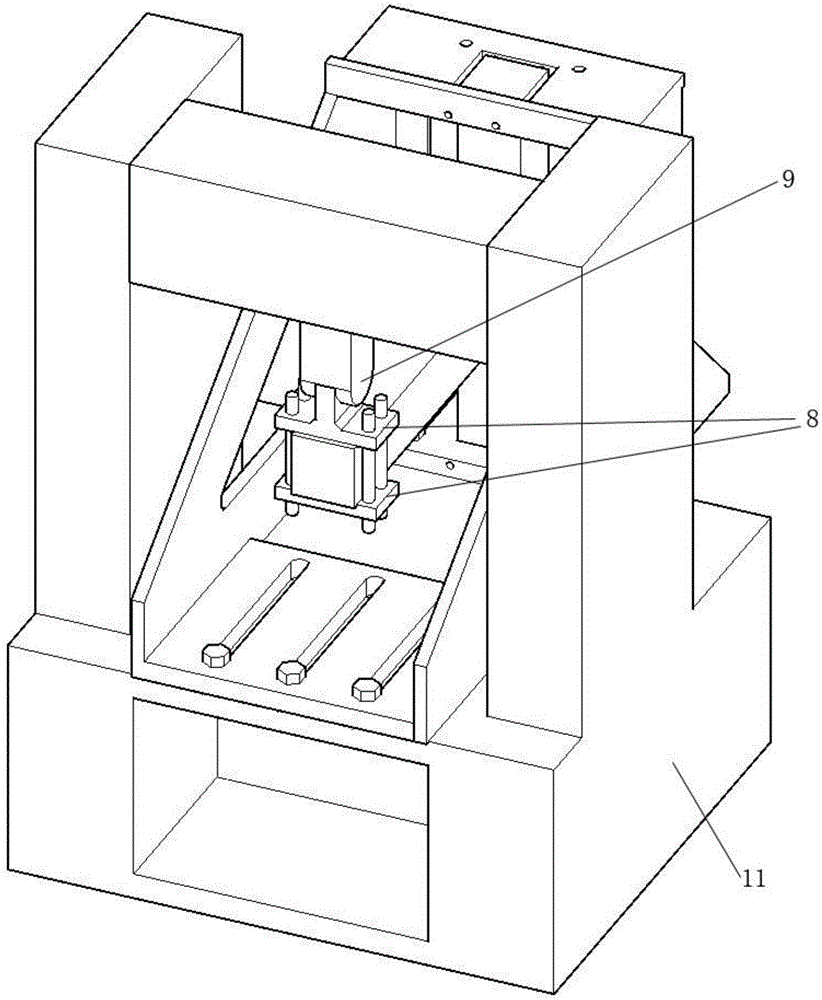

[0039] Such as figure 1 As shown, a test device that can be used for the mechanical performance test of light steel frame beam-column joints, the device includes a device bottom plate (1) assembled and fixed with a universal testing machine, a lower clamping groove (2) for assembling light steel frame columns, Upper clamping slot (3), fastening bolts (4) for fixing the light steel frame column, upper cover plate (5) for fixing the light steel frame column, long groove of the bottom plate for changing the position of the loading point (6), connecting the bottom plate and The side plate (7) of the top plate, the splint (8) loaded at the beam end, the hinge rod (9) of the loaded end, the beam-column connection node specimen (10), and the mechanical universal testing machine (11). The test device is made of 15-35mm thick steel plate after cutting, milling, welding, painting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com