Method and device for determining uniform ductility of hi-grade steel pipeline steel pipe

A technology with elongation and high steel grade, applied in the field of pipeline steel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

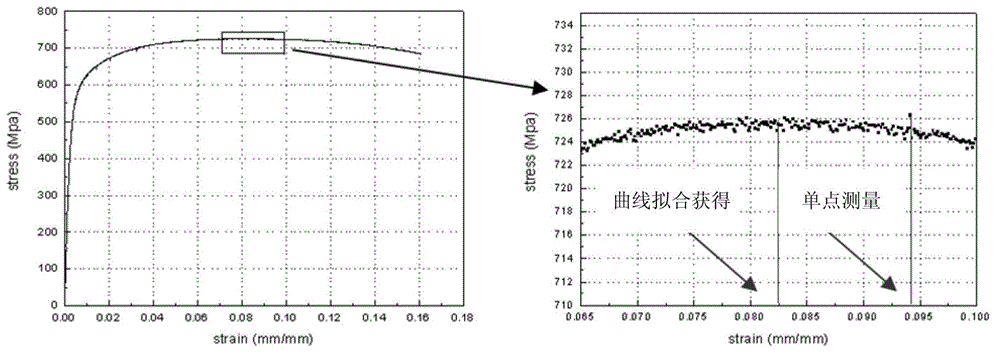

[0020] The embodiment of the present invention provides a method for determining the tensile uniform elongation of a high-grade pipeline steel pipe. By fitting the engineering stress-engineering strain curve of the tensile test within a certain range, the mathematical expression of the material tensile curve is obtained, In this way, the true uniform elongation value of the material can be determined, so as to objectively judge the deformation performance of the steel pipe and avoid misjudgment.

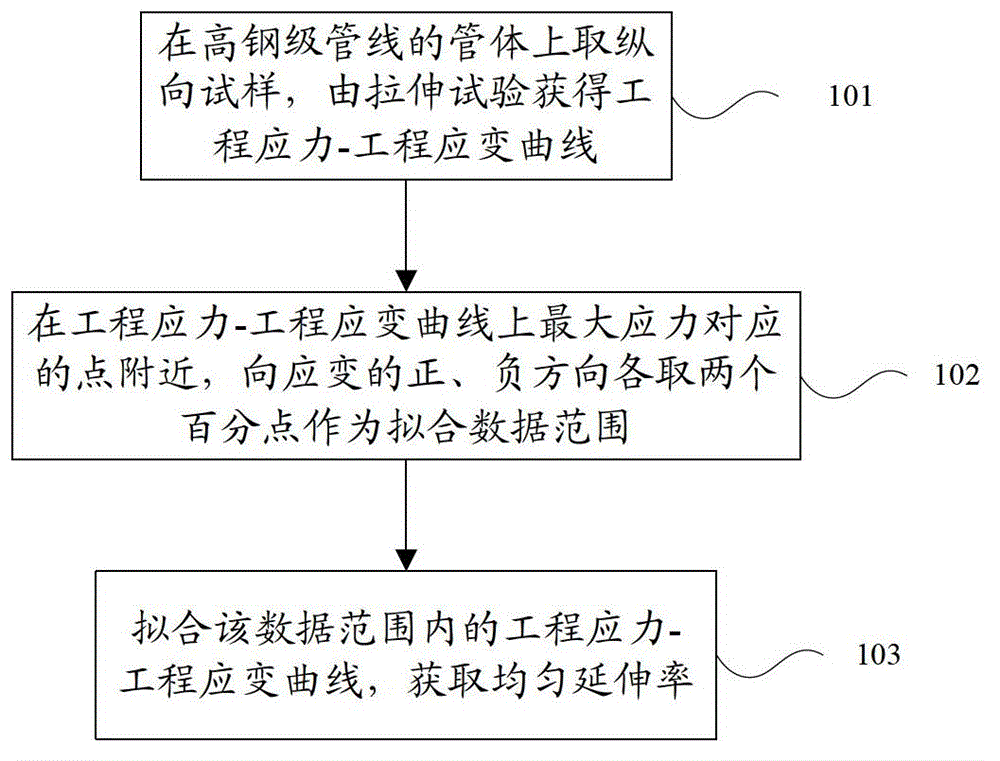

[0021] figure 1 The flow chart of the method for determining the uniform elongation of high-grade pipeline steel pipe provided by the embodiment of the present invention adopts the following steps:

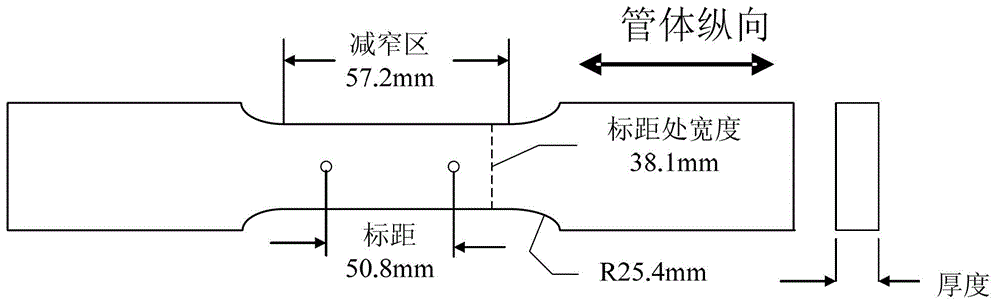

[0022] Step 101, take a tensile sample on the pipe body of the high-gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com