Direct-shear measuring method of drilling rock mass specimen preparation

A technology of sample preparation and testing method, which is applied in the field of scientific experiments, can solve the problems of high test cost, long test period, dependence on masons, etc., and achieve the effect of convenient operation, simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

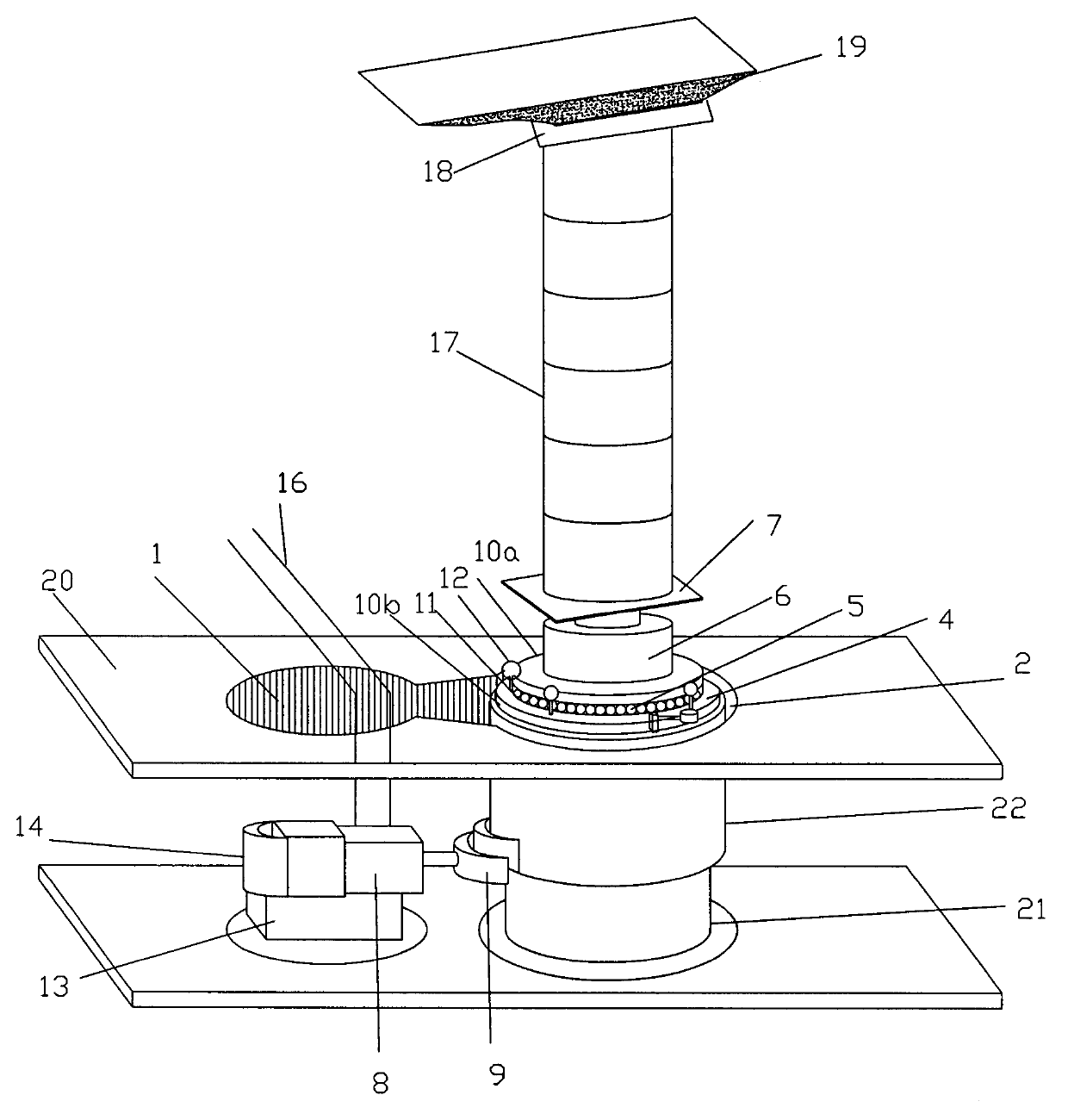

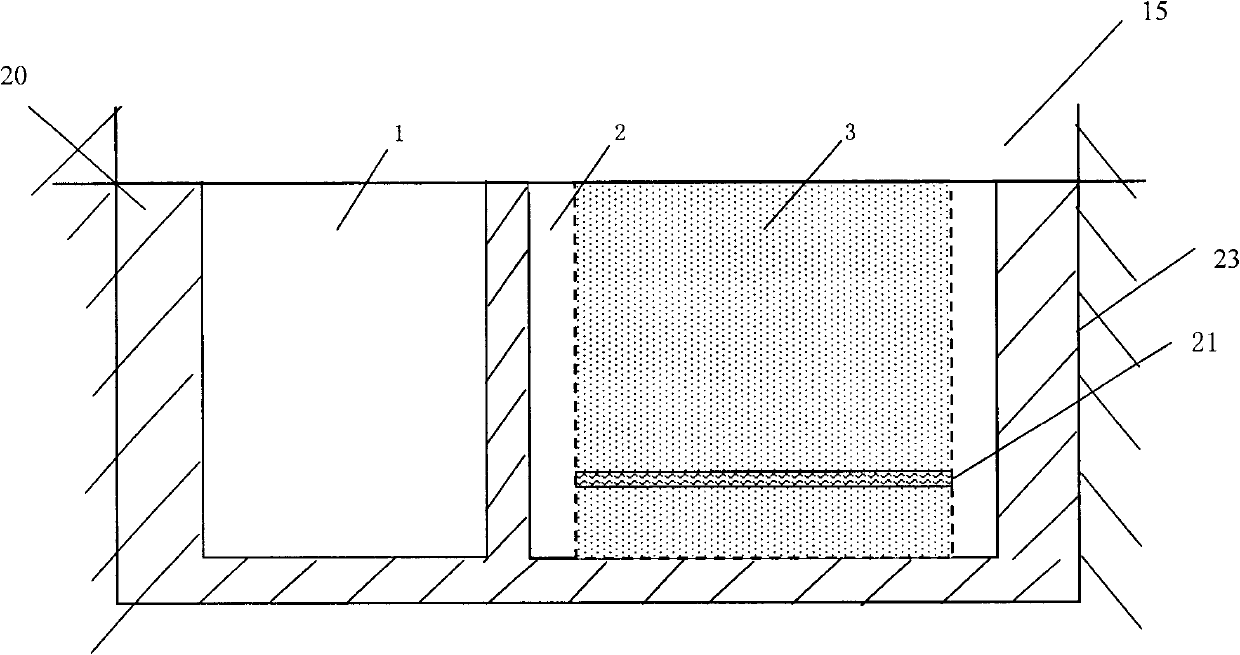

[0021] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] Depend on figure 1 , figure 2 As shown in the figure, a 2m×2m test flat hole 15 is first excavated in the mountain 23 by conventional blasting method, and then two holes are drilled downward with a large-diameter drilling rig on the test flat hole bottom plate 20, one hole is the shear hole 1, The other hole is the specimen hole 2. The centers of the two holes are on a straight line. The direction of the straight line is consistent with the direction of the engineering force. The distance between the adjacent hole walls of the two holes is 5-10 cm. In the hole, as sample 3, the core is taken out of the shear hole to install the shear test equipment, and then the rock mass in the middle of the two holes is cut and connected. The diameter of the specimen hole is 70cm, the diameter of the core, that is, the test sample, is 60cm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com