Variable-rate stretching curve evaluation method

An evaluation method and variable rate technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as large random errors, and achieve the effect of overcoming large random errors and meeting the needs of CAE collision simulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Set seven strain rates of 0.01, 0.1, 1, 10, 100, 200, and 400 according to actual needs, and select three samples for variable-rate tensile tests at the same strain rate.

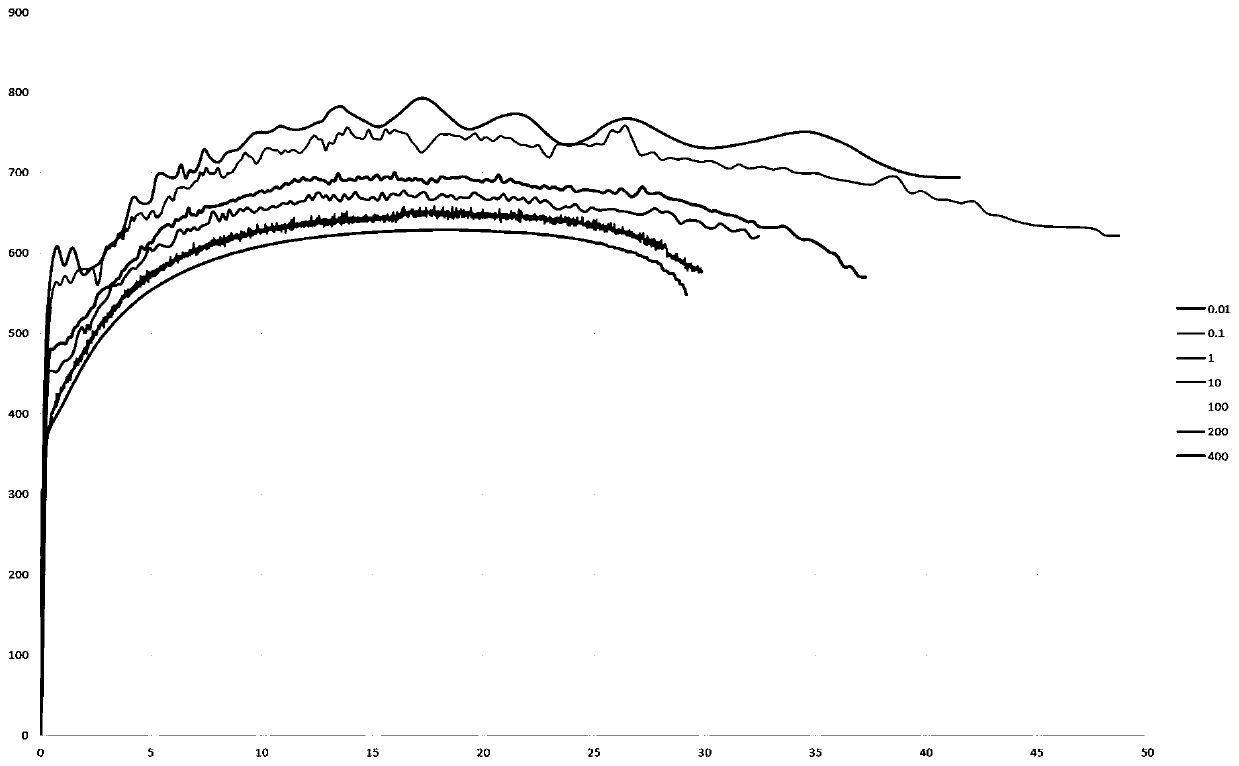

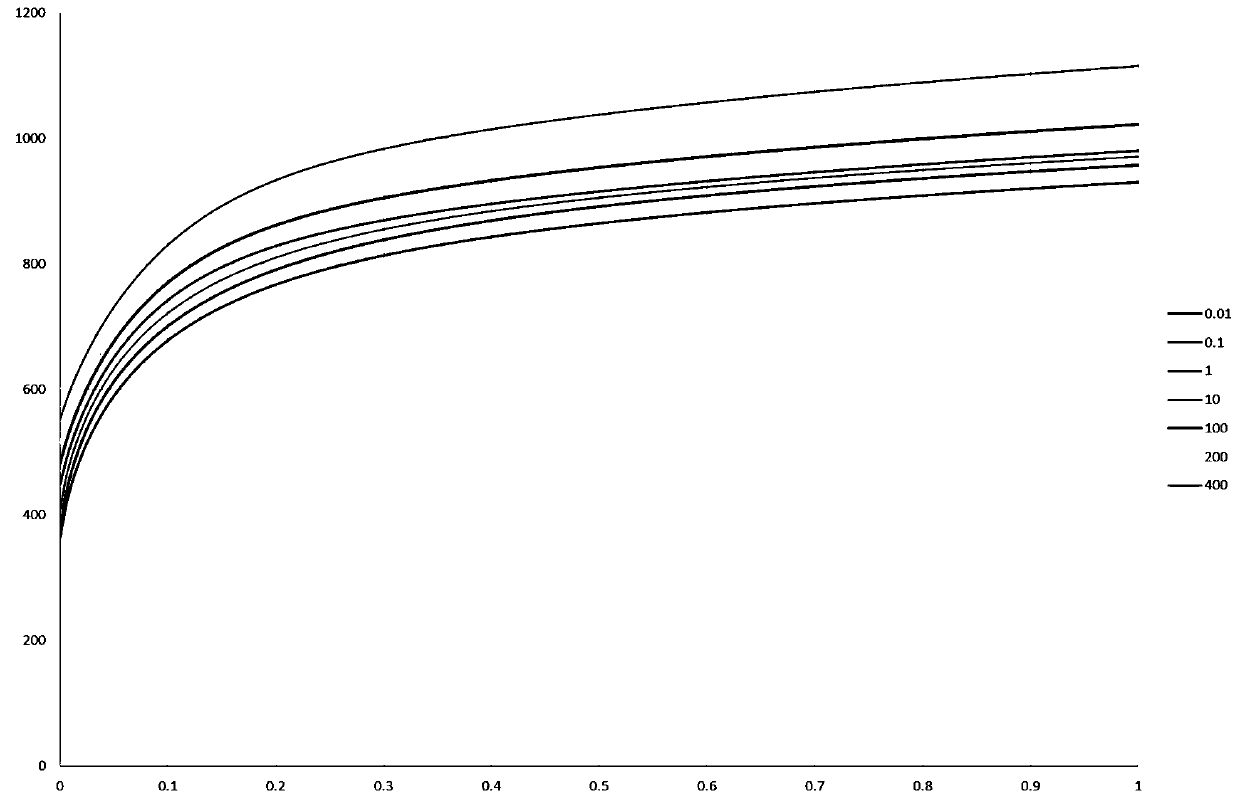

[0025] 2) Obtain the engineering stress-strain curves of each sample at different strain rates (such as figure 1 Shown) and yield, tensile strength (as shown in Table 1).

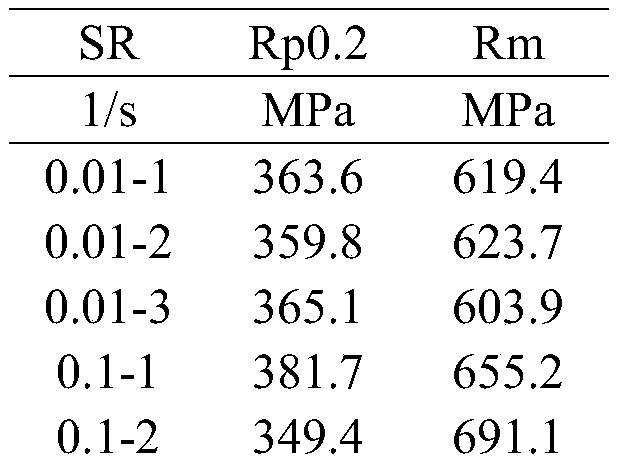

[0026] Table 1

[0027]

[0028]

[0029] 3) When the strain rate does not exceed 100, the yield and tensile strength of each sample under the strain rate of 0.01 and 0.1, 0.1 and 1, 1 and 10, and 10 and 100 are compared in order from small to large, If the current strain rate is increased by 10 times, if the yield and tensile strength of the material are increased within the range of 2% to 10%, the curves of the sample meet the non-overlapping processing requirements. Conversely, if the increase in yield and tensile strength of the material is not within the range of 2% to 10%, the sample cannot meet the processing req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com