Production formula and process of waterproof roll sizing material

A technology for waterproofing membrane and production formula, which is applied in the direction of asphalt material adhesive, adhesive, film/flaky adhesive, etc. The effect of less parts content, less penetration, improving physical and mechanical properties and construction applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0087] This example provides a formula to improve the production of S-CLF YC 1.5mm products, which is made by mixing liquid material, powder material and granular material, and the weight percentages are as follows:

[0088] Table 1 A side rubber formula

[0089] raw material number of copies asphalt 54 35# oil 3 SBS3501 6 95% SBR 2 Butyl rubber 0327 2 Resin 138# 5 200 mesh stone powder 28

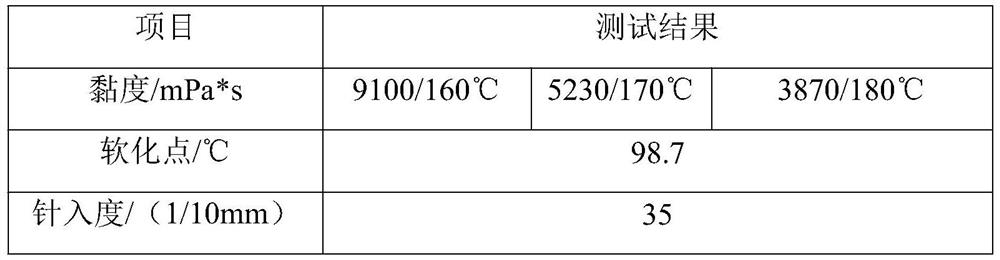

[0090] Table 2 Test results of surface A rubber material

[0091]

[0092] Table 3 B side rubber formula

[0093] raw material number of copies asphalt 47 35# oil 8 SBS3501 7.5 98% SBR 1 Butyl rubber 0327 4 thermal crosslinking agent 0.06 stabilizer 0.04 200 mesh stone powder 32.4

[0094] Table 4 Test results of surface B rubber

[0095] project standard value Test Results Result judgment low temperature flexible -27℃, no cracks -27℃, no cr...

Embodiment example 2

[0101] This example provides a formula to improve the production of S-CLF YC 1.5mm products, which is made by mixing liquid material, powder material and granular material, and the weight percentages are as follows:

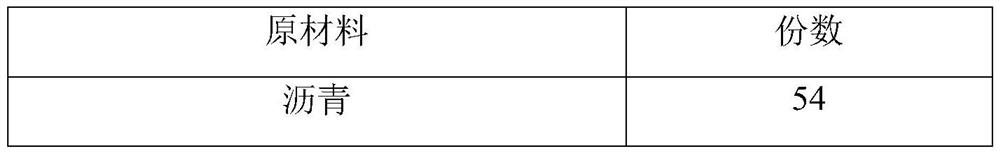

[0102] Table 6 A side rubber formula

[0103]

[0104]

[0105] Table 7 Test results of surface A rubber material

[0106]

[0107] Table 8 B side rubber formula:

[0108] raw material number of copies asphalt 48 35# oil 9 SBS3501 6 98% SBR 1 Butyl rubber 0327 4 thermal crosslinking agent 0.06 stabilizer 0.04 200 mesh stone powder 32.4

[0109] Table 9 Test results of surface B rubber

[0110] project standard value Test Results Result judgment low temperature flexible -27℃, no cracks -27℃, no cracks qualified

[0111] The A side rubber material and the B side rubber material are molded according to the specific thickness ratio (1:3) of the coil, and the cros...

example 3

[0118] This example provides a formula to improve the production of S-CLF YC 1.5mm products, which is made by mixing liquid material, powder material and granular material, and the weight percentages are as follows:

[0119] Table 11 A side rubber formula

[0120] raw material number of copies asphalt 52 35# oil 4 SBS3501 5 95% SBR 1 Butyl rubber 0327 4 Resin 138# 4 200 mesh stone powder 30

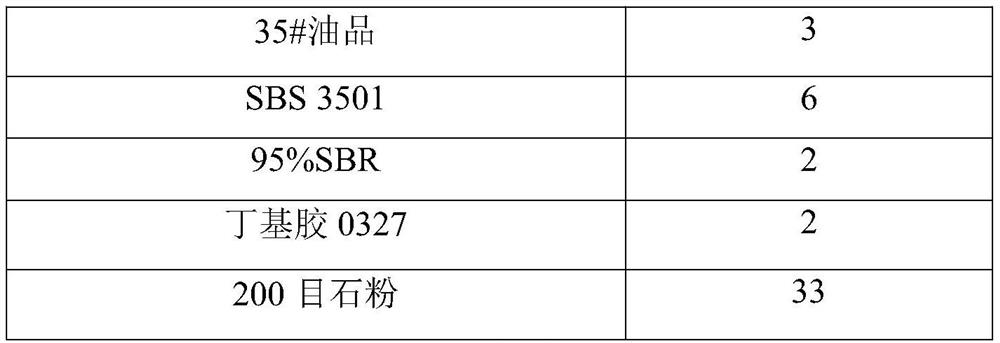

[0121] Table 12 A side rubber test results

[0122]

[0123] Table 13 B side rubber formula

[0124]

[0125]

[0126] Table 14 B side rubber test results

[0127] project standard value Test Results Result judgment low temperature flexible -27℃, no cracks -27℃, no cracks qualified

[0128] The A side rubber material and the B side rubber material are molded according to the specific thickness ratio (1:3) of the coil, and the cross-laminated film reinforcement layer is 0.265mm in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com