Waterborne VOCs absorption liquid and preparation method thereof

An absorbing liquid and water-based technology, applied in the environmental field, can solve the problems of difficult recovery and high cost of absorbing liquid, and achieve the effects of low volatilization, enhanced emulsifying effect, and increased solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

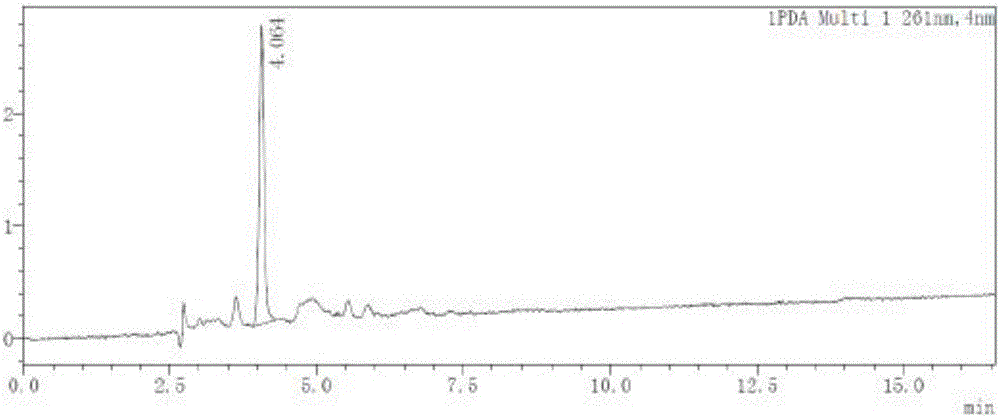

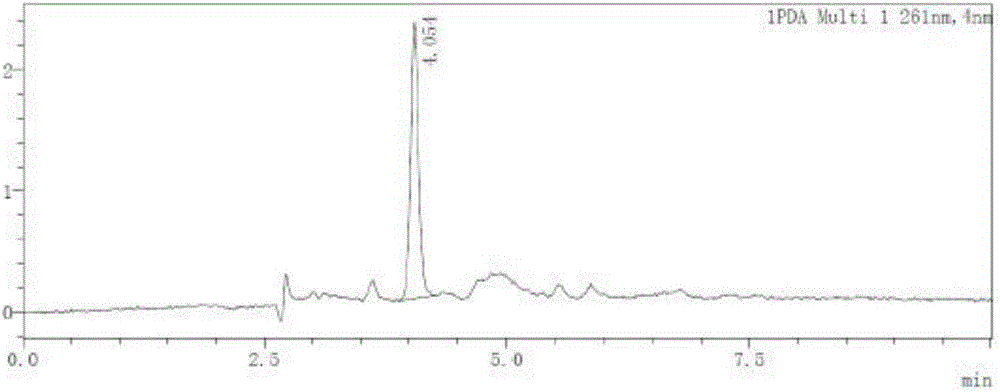

Image

Examples

Embodiment 1

[0049] VOCs absorbing liquid, the components by weight include:

[0050] 2% nonionic surfactant, nonionic surfactant can be Tween-20, AEO-14-2, fatty acid polyoxyethylene, nonionic surfactant includes at least one;

[0051] 1% anionic surfactant, the anionic surfactant can be fatty amine-polyoxyethylene ether-sodium sulfate, fatty acid sulfoalkyl ester, sodium alkylbenzene sulfonate, the anionic surfactant includes at least one;

[0052] 1% FSO100 fluorocarbon surfactant;

[0053] 1% FSN100 fluorocarbon surfactant;

[0054] 1% emulsifier;

[0055] 5% asphalt mineral oil;

[0056] The balance is water.

Embodiment 2

[0058] VOCs absorbing liquid, the components by weight include:

[0059] 1% nonionic surfactant, nonionic surfactant can be Tween-20, AEO-14-2, fatty acid polyoxyethylene, nonionic surfactant includes at least one;

[0060] 5% anionic surfactant, the anionic surfactant can be fatty amine-polyoxyethylene ether-sodium sulfate, fatty acid sulfoalkyl ester, sodium alkylbenzene sulfonate, the anionic surfactant includes at least one;

[0061] 5% FSO100 fluorocarbon surfactant;

[0062] 5% FSN100 fluorocarbon surfactant;

[0063] 3% emulsifier;

[0064] 10% Whetstone Ester Mineral Oil;

[0065] The balance is water.

Embodiment 3

[0067] VOCs absorbing liquid, the components by weight include:

[0068] 3% nonionic surfactant, nonionic surfactant can be Tween-20, AEO-14-2, fatty acid polyoxyethylene, nonionic surfactant includes at least one;

[0069]2% anionic surfactant, the anionic surfactant can be fatty amine-polyoxyethylene ether-sodium sulfate, fatty acid sulfoalkyl ester, sodium alkylbenzene sulfonate, the anionic surfactant includes at least one;

[0070] 1% FSO100 fluorocarbon surfactant;

[0071] 1% FSN100 fluorocarbon surfactant;

[0072] 1% emulsifier;

[0073] 5% asphalt mineral oil;

[0074] 0.04% butanol;

[0075] The balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com