Deviation correcting and resetting method for transverse deviation of beam bodies of beam bridge

A reset method and beam body technology, which is applied in bridges, bridge construction, bridge maintenance, etc., can solve problems such as few researches on treatment methods, and achieve the effects of simple structure, small construction impact, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

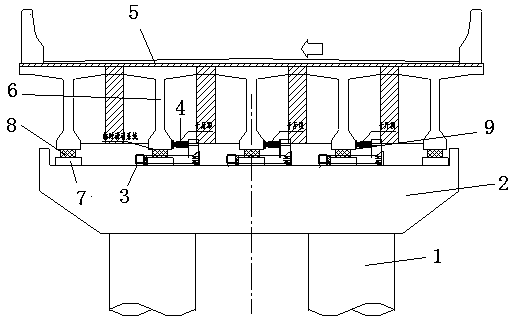

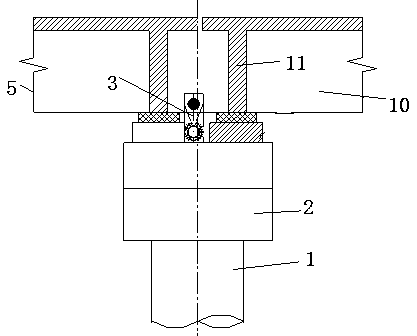

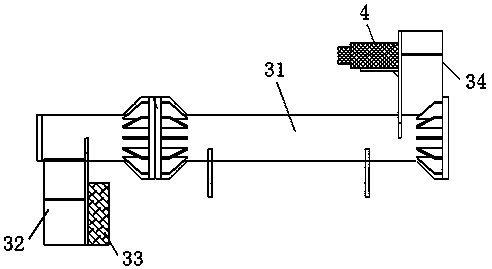

[0029] The method for rectifying and resetting after the horizontal deviation of the girder and bridge body of the present invention, the steps are:

[0030] 1) Eliminate the horizontal lateral force that causes the beam to deflect;

[0031] Since there may be many factors for the lateral deviation of the beam body, and even some reasons have not been recognized, so the elimination here is just to eliminate as much as possible, not necessarily to eliminate them all. According to the existing analysis, it is found that there are two main influencing factors: the inclination of the bridge pier and the lack of level installation of the steel plate on the support. If the horizontal lateral force is caused by the steel plate on the support not being installed horizontally, the elimination method is: weld the wedge-shaped steel plate under the bottom steel plate of all offset beams of the offset joint, and the bottom steel plate of the offset beam and the wedge-shaped steel plate T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com