Detecting based on concrete box beam bridge web vertical pre-stress rib stretching force

A vertical prestressed, concrete box girder technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems of low precision, high cost, web cracking, etc., and achieve the effect of simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

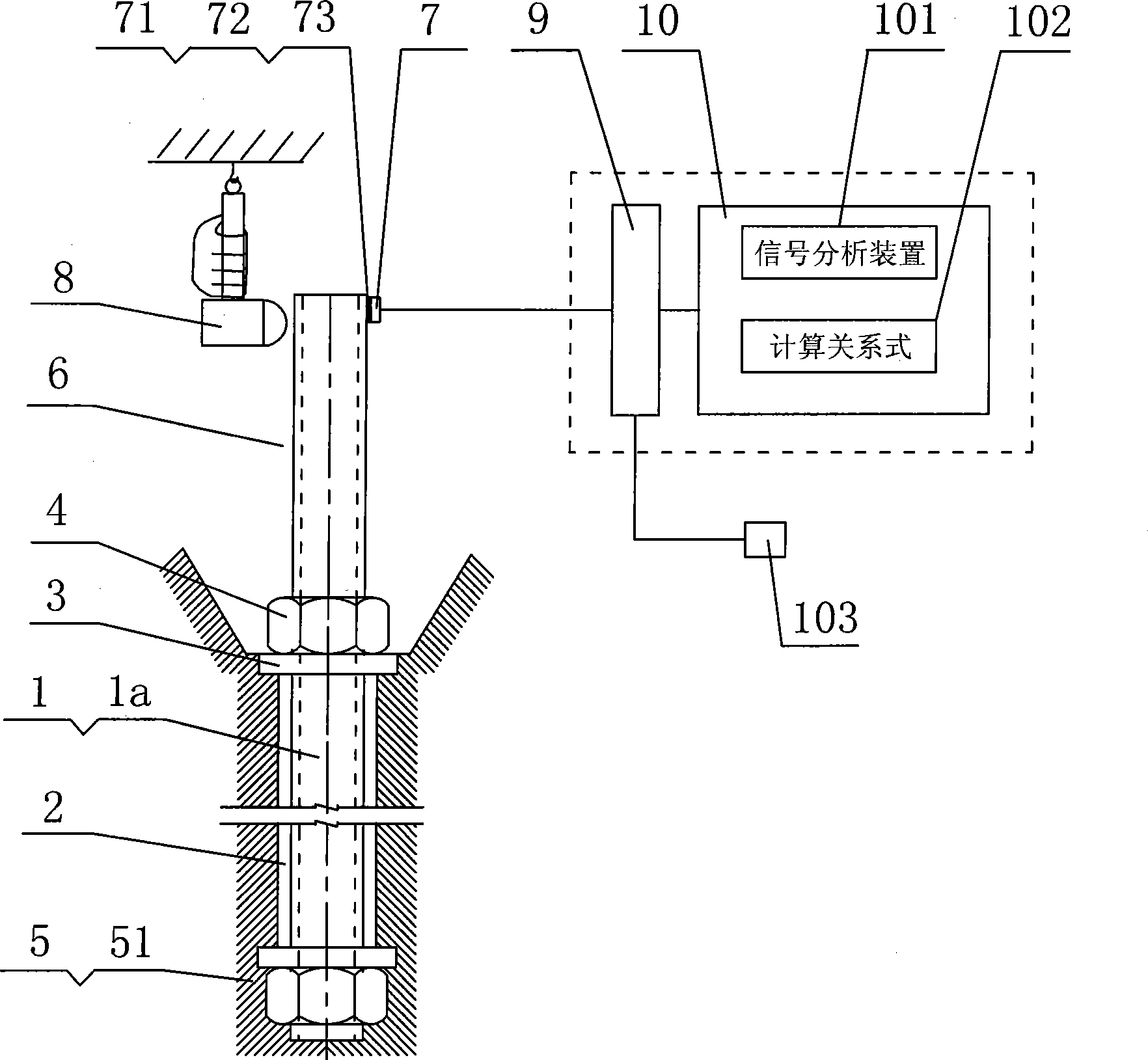

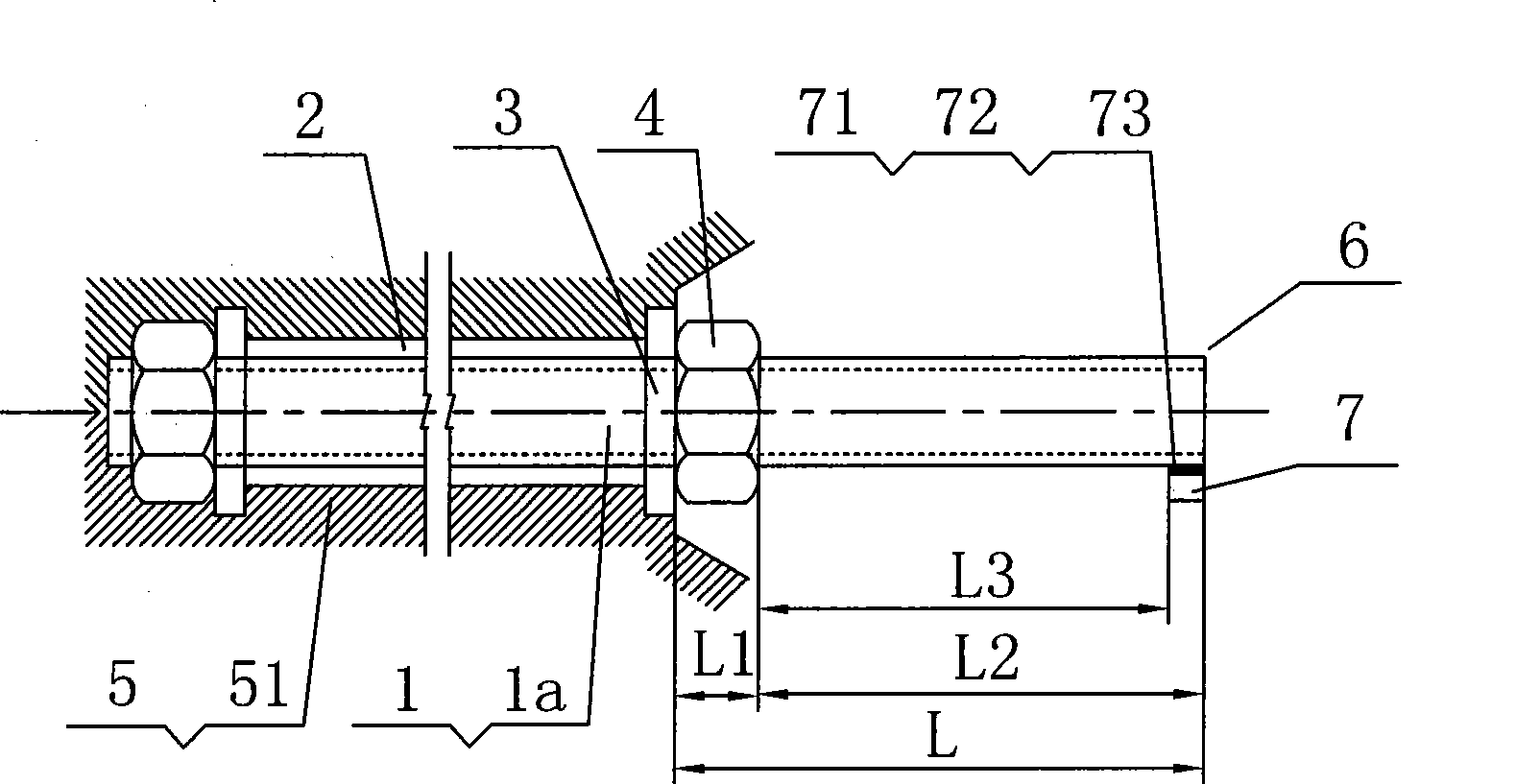

[0026] ① The construction unit installs ordinary steel bars according to the design drawings of the concrete box girder bridge, in which the threaded steel bars 1 are covered with corrugated sleeves 2, and anchor pads 3 and nuts 4 are installed at the upper and lower ends of the web of the threaded steel bars 1. During construction, first Set up the template according to the figure, pour the concrete 51 of the web of the box girder bridge, and form the web 5 of the concrete box girder bridge after the concrete reaches the strength. The plate 3 and the nut 4 work together with the web plate 5 of the concrete box girder bridge, so that the threaded steel bar 1 is subjected to tension to form the vertical prestressed tendon 1a of the web plate, and the exposed section 6 is arranged on the upper part of the vertical prestressed tendon 1a as required. The length of section 6 must be reserved when stretching the threaded steel bar 1. According to the requirements of the construction ...

Embodiment B

[0029] ① After the construction operation, the process of transforming the threaded steel bar 1 into the vertical prestressed tendon 1a is completed. According to the requirements, the length of the upper exposed section 6 of the vertical prestressed tendon 1a should be greater than 2.5 times the diameter of the vertical prestressed tendon 1a. The length of the upper exposed section 6 of the prestressed tendon 1a should be 80mm longer than the reserved length for tensioning construction. The vertical prestressed tendon 1a is selected from the threaded steel bar 1 with a diameter of 32mm commonly used on bridges at present, the thread type is M34×3.0, and the matching nut 4 The height is 55mm, the shape is hexagonal, the distance across sides is 55mm, and the length of the exposed section 6 is equal to 116mm.

[0030] ②The top of the exposed section 6 is fixedly installed with the acceleration sensor 7 through the magnetic suction seat 71 or rubber mud 72 or gypsum mud 73. The v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com