External prestress strengthening method for prestressed concrete box-beam bridge

A technology of external prestressing and concrete box girder, which is applied in bridge reinforcement, bridge, bridge maintenance, etc. It can solve the problems of difficult construction, interruption of bridge deck traffic, large engineering volume, etc., and achieve enhanced web stiffness and shear resistance Power, less side effects, less economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

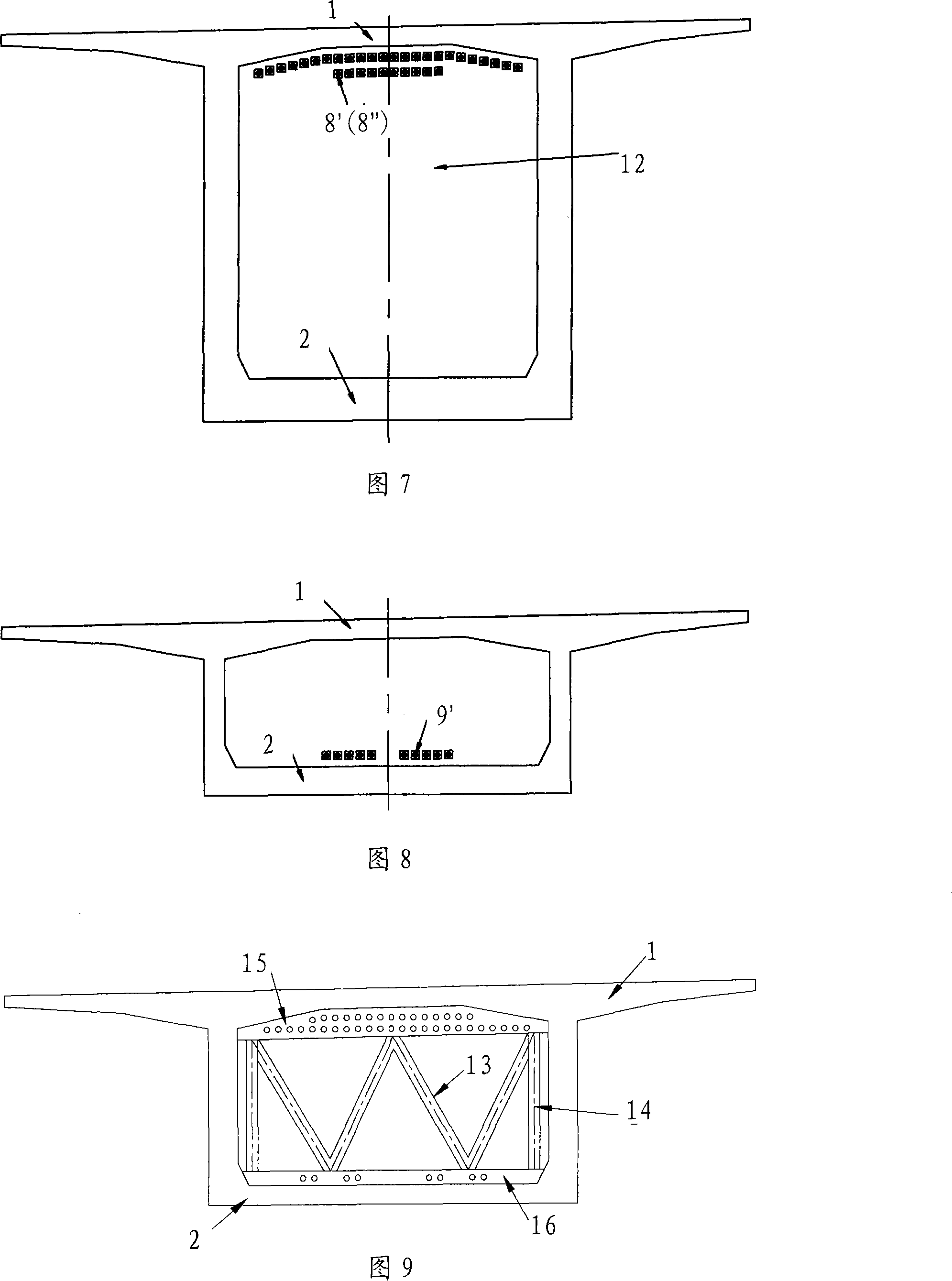

[0023] The present invention will be further described below in conjunction with embodiment and accompanying drawing, and this embodiment is a prestressed concrete continuous box girder bridge with a span of (65.425+126+65.425) m.

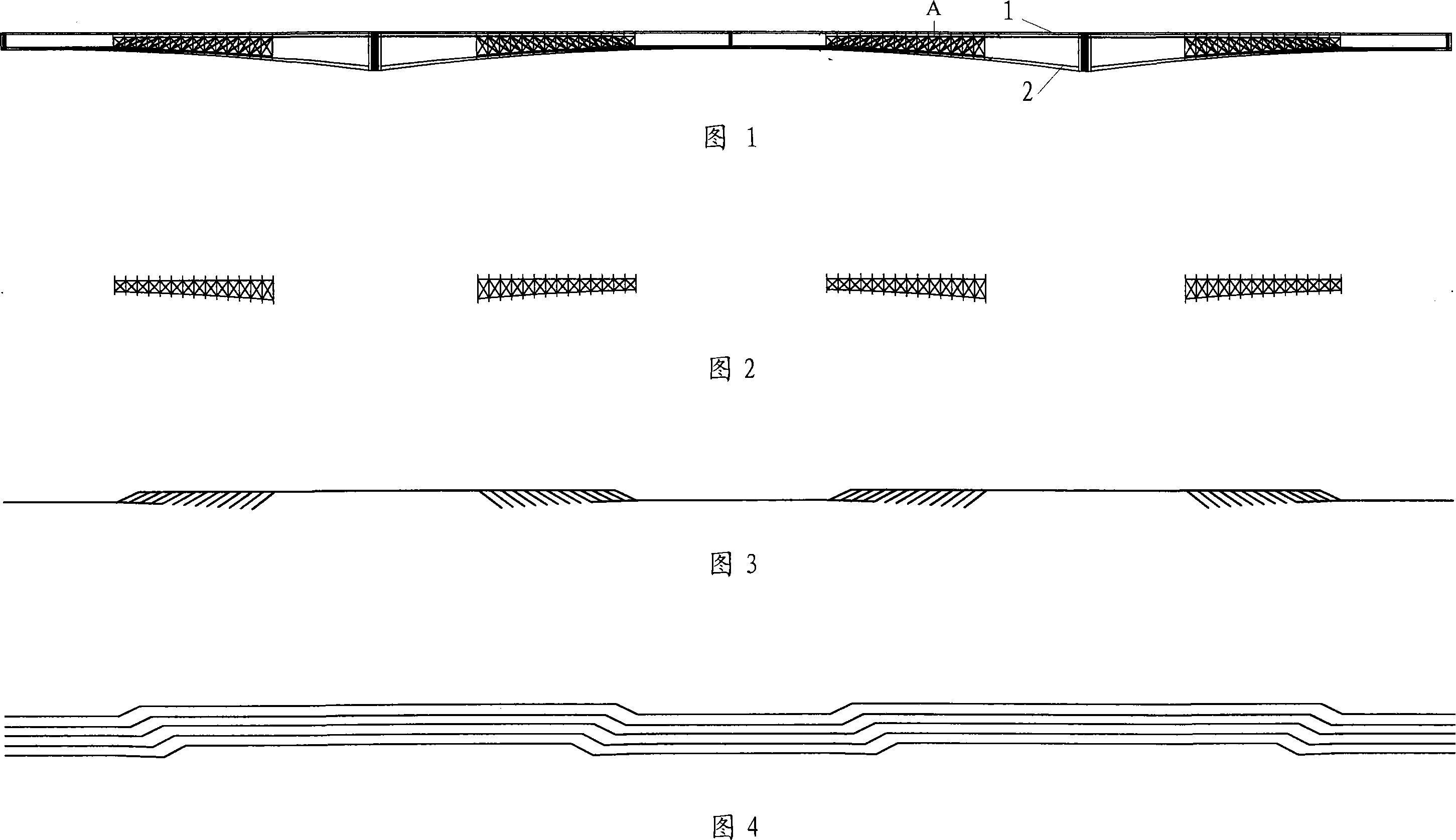

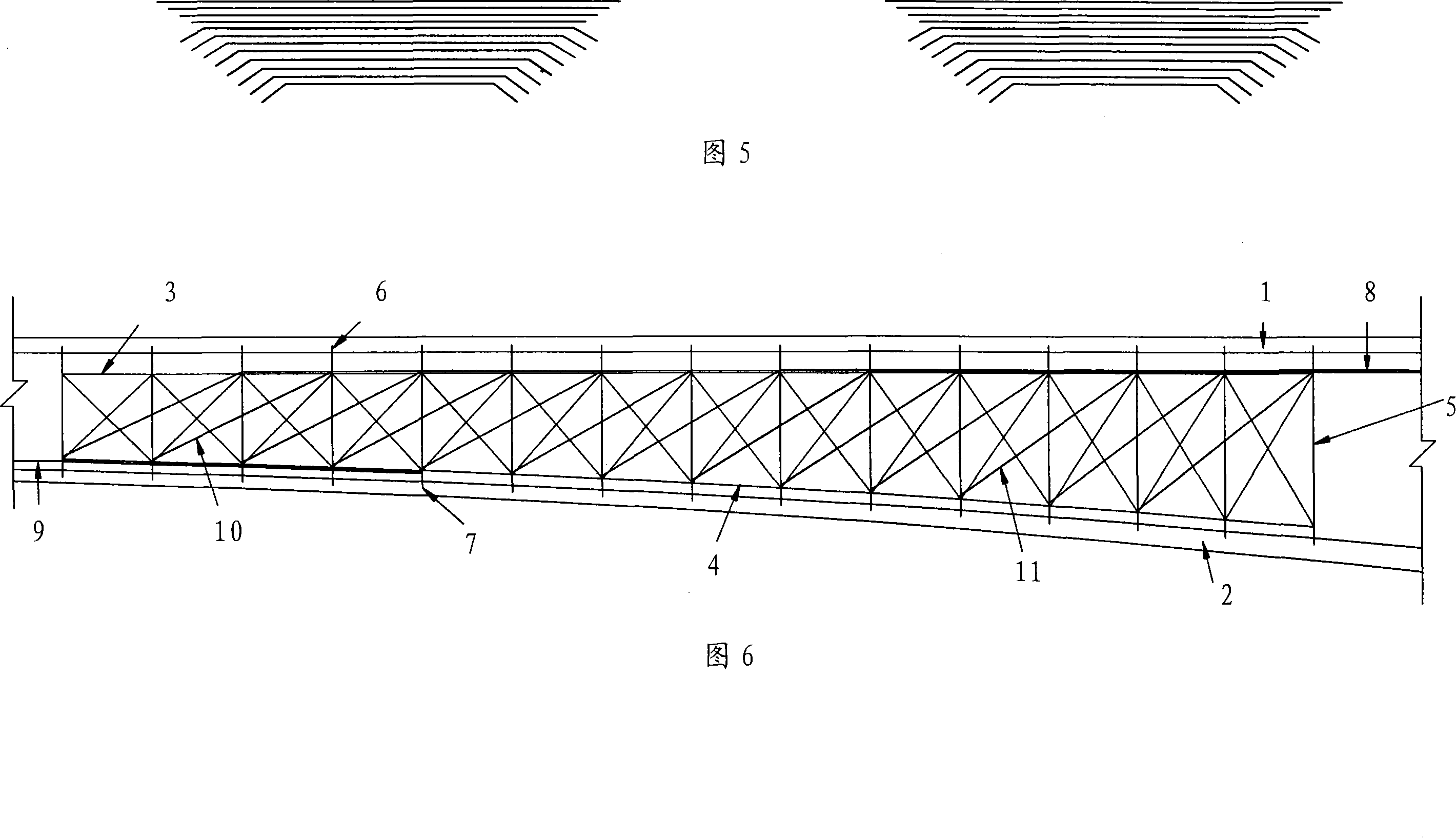

[0024] Fig. 1 is a schematic diagram of the general layout of the longitudinal bridge of the embodiment of the present invention. Aiming at the specific structure in this embodiment, the plane bar system finite element program is used to calculate the nodal force influence line concerned with the mechanical parameters of the section, and the optimal arrangement of the external prestressed long beam and the external prestressed roof short beam is obtained by using the influence line , considering the stress of the structure to determine the final layout of the external prestressing; Figure 3 is a schematic diagram of the longitudinal bridge layout of the external prestressing beams in the embodiment of the present invention, and Figure 4 is the enlar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com