Descending bracket self-mobile model framework bridge fabrication machine

A technology of moving formwork and bridge-building machine, applied in the field of bridge-building machine, can solve the problems such as unavailability of advantages and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

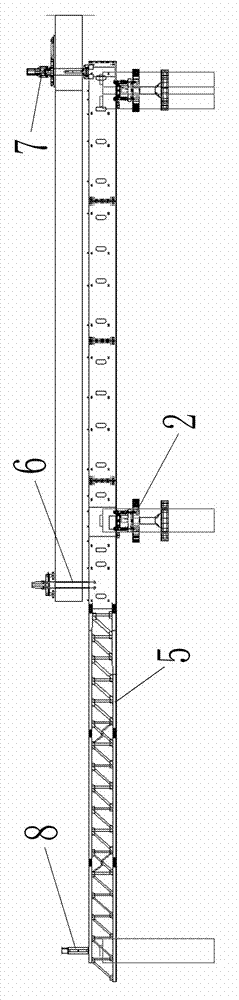

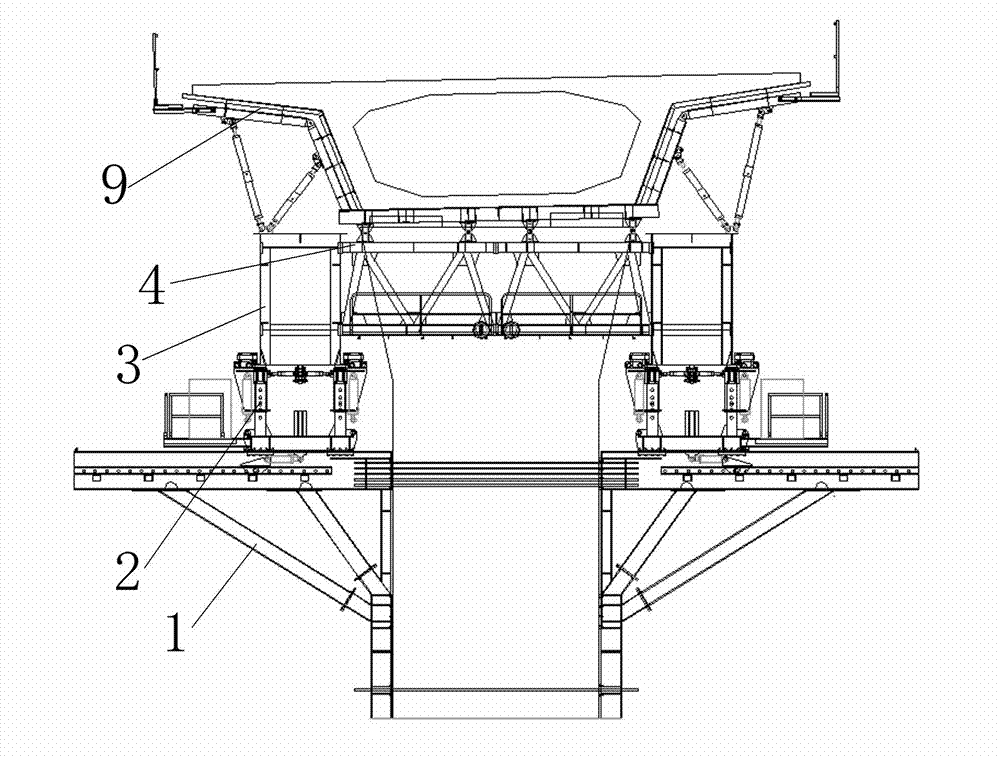

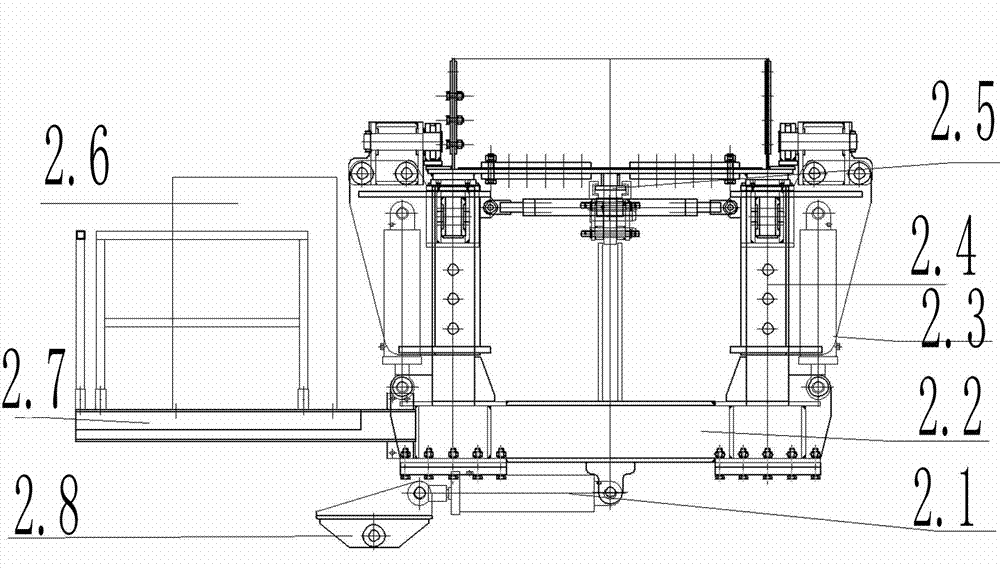

[0030] Attached below figure 1 to attach Figure 13 The present invention will be further described.

[0031] as attached figure 1 , attached figure 2As shown, the downward corbel self-moving formwork bridge building machine includes a corbel 1 supported on the pier body, a walking trolley system 2 installed on the top sliding surface of the corbel 1, a main girder 3, and two main girders. 3 and the beam 4 fixed on the main beam 3, the formwork system fixed on the beam 4 for supporting and adjusting the concrete box girder 9, the mid-hanging point beam 6 fixed on the concrete box girder, the nose beam 5, fixed on the bridge pier The front support beam system on 8.3 and the C beam 7 fixed on the main beam 3 and movable along the concrete box girder, the main beam 3 is supported on the traveling trolley system 2, and the traveling trolley system 2 drives the corbel 1 along the main beam 3 moves, the rear end of the nose bridge 5 is connected to the main beam 3, and its fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com