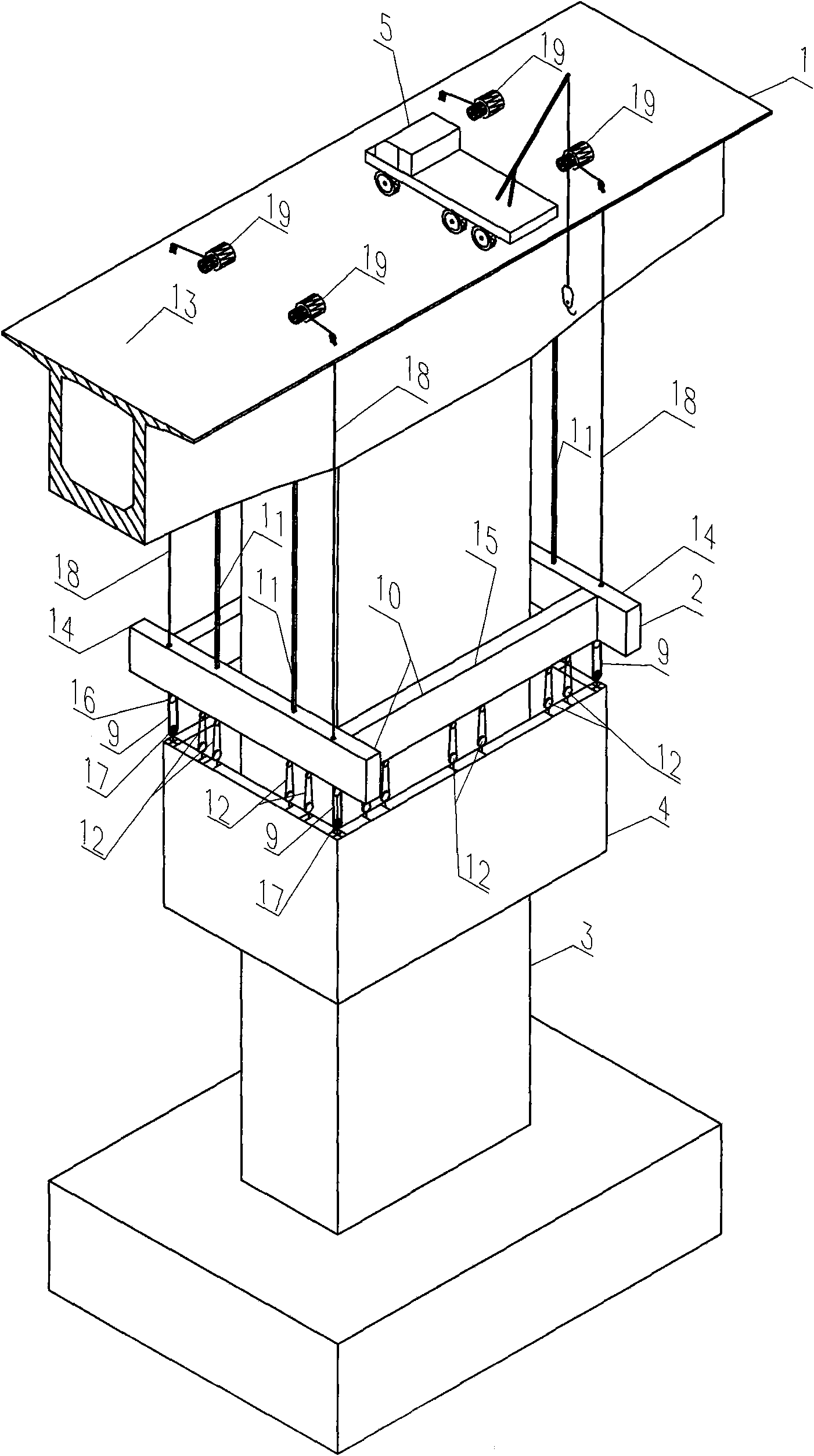

Construction method of steel cofferdam used for reinforcing underwater pier

A construction method and bridge pier reinforcement technology, applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve problems such as limited construction space, secondary damage to bridges, impossibility of implementation, etc., achieve small construction area occupied, short preparation period, and auxiliary equipment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

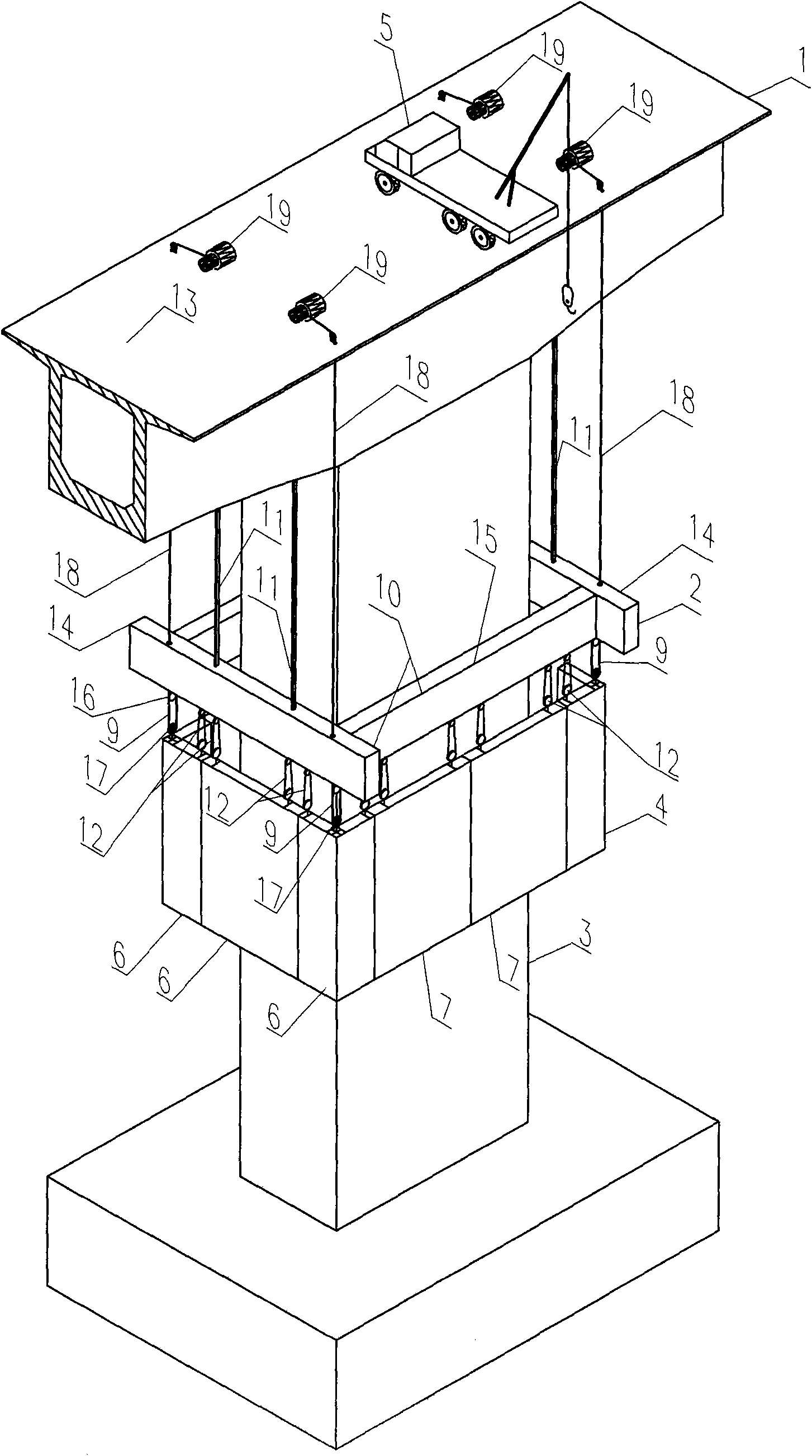

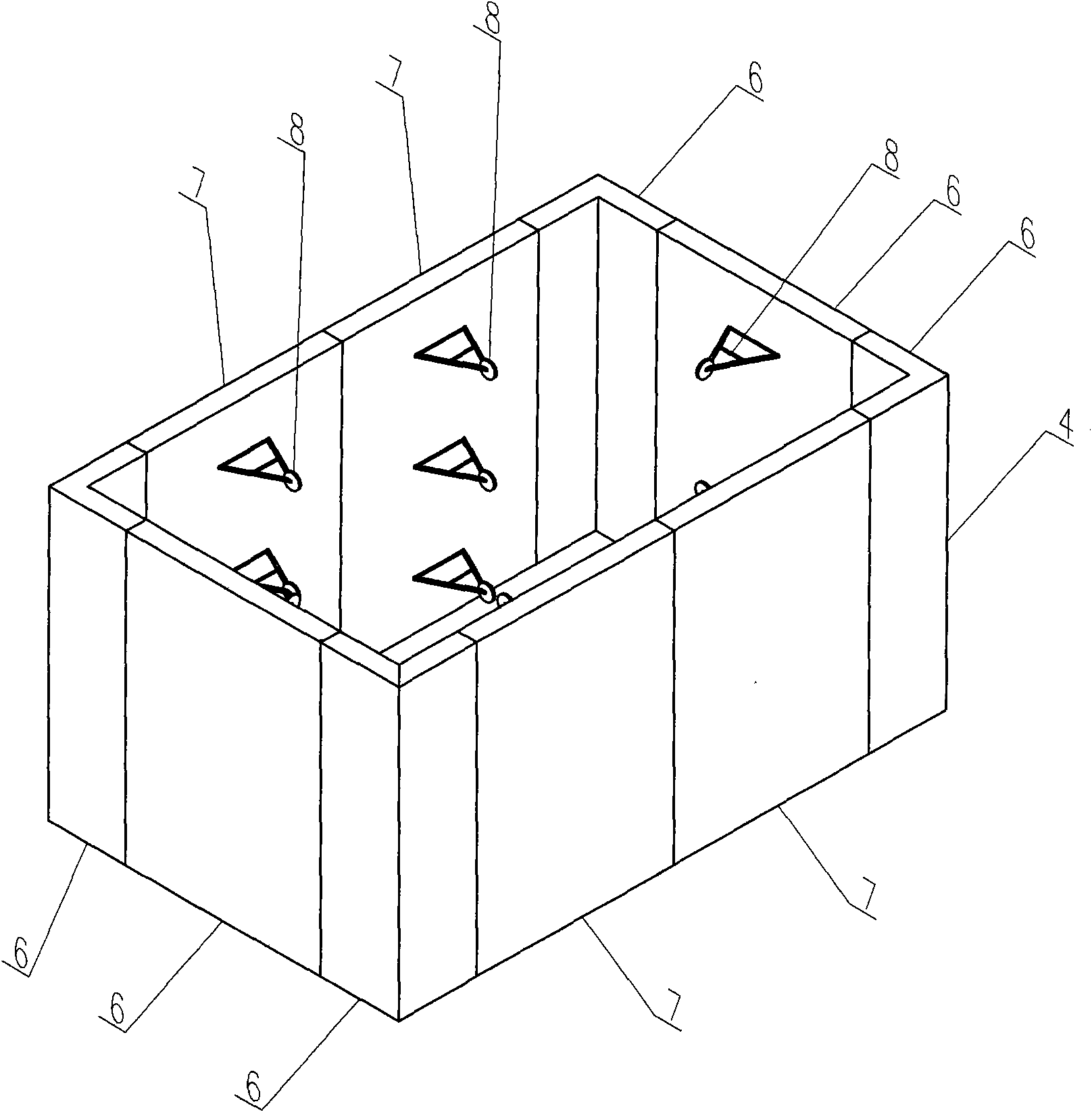

[0046] The construction method of the steel cofferdam for underwater pier reinforcement of the present invention, in addition to completing the assembly of the first segment of the steel cofferdam 4 on the steel frame 2, the steel cofferdam 4 is assembled with the steel cofferdam sinking block 9 Put water under the first section or inject water into it so that the top surface is 1-1.5m above the water surface, and then complete the assembly of the second section of the steel cofferdam 4 on the steel frame 2, and use the cofferdam The second section of the steel cofferdam 4 is lowered by the block block 9 until the bottom surface of the second section is located at the top surface of the first section, and then the connection between the first section and the second section is completed and merged into the water Sink until the top surface of the second section is 1-1.5m above the water surface, and repeat this until the assembly of all sections of the entire steel cofferdam 4 is...

Embodiment 3

[0048] The construction method of the steel cofferdam for underwater pier reinforcement of the present invention is the same as that of the embodiment except that the steel girder 10 forming the steel frame 2 is composed of a steel composite beam, and the crane 5 placed on the bridge deck 13 is a crawler crane. 1 is the same.

Embodiment 4

[0050] The construction method of the steel cofferdam for underwater pier reinforcement of the present invention is the same as that of Embodiment 1 except that the steel girder 10 forming the steel frame 2 is made of steel pipe girders, and the crane 5 placed on the bridge deck 13 is a gantry crane. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com