Integral erection construction method of 60m steel box girder

A construction method and technology of steel box girders, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve problems such as high safety and quality risks, inability to meet the requirements of large crane construction sites, and large welding workload. Achieve the effects of reducing assembly and welding procedures, facilitating the organization of flow construction, and ensuring quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

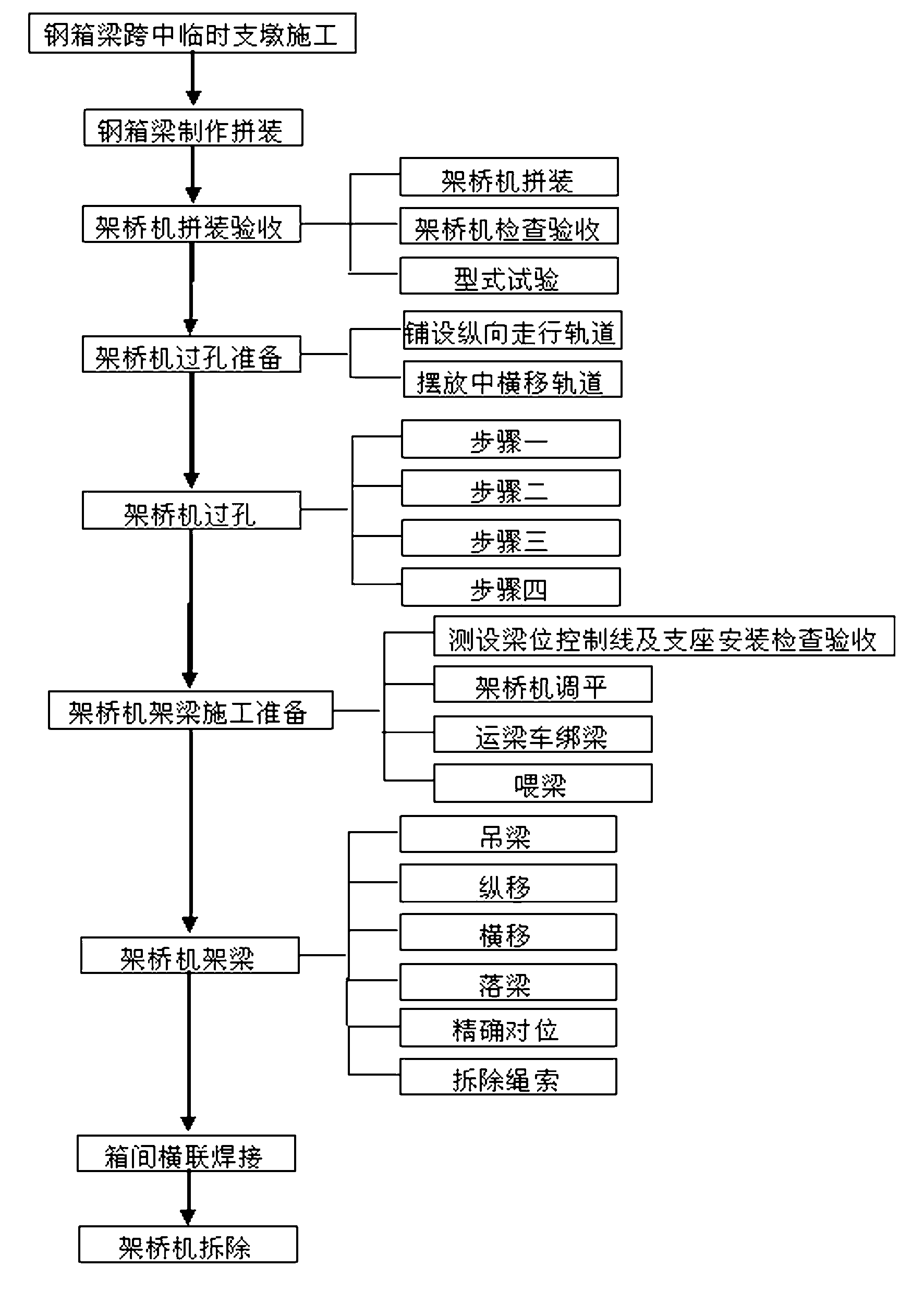

[0100] The construction method of the overall erection of 60m steel box girder is carried out by using the fasting box-shaped double-girder bridge erecting machine. Hole construction preparation → bridge erecting machine passing the hole → bridge erecting frame girder construction preparation → bridge erecting frame girder → cross connection welding between boxes → bridge erecting machine dismantling, such as figure 1 shown.

[0101] Taking the project described in the background technology as an example, the specific steps are as follows:

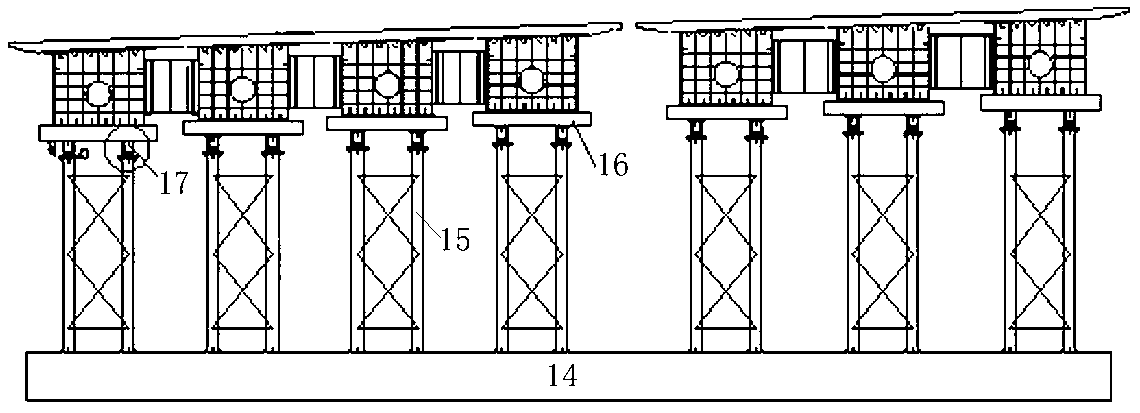

[0102] 1. Construction of temporary buttresses in the mid-span of steel box girders

[0103] Since the 60m steel box girder is a steel-concrete composite girder, the joint force can only be exerted after the concrete pouring of the bridge deck is completed. Therefore, when the steel box girder is erected by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com