Spreading method for preventing steel box girder bridge face bituminous concrete from being pushed

A technology of asphalt concrete and steel box girders, applied in the field of material science and engineering, to achieve the effects of preventing cracking, improving bonding conditions, and increasing bond strength and shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

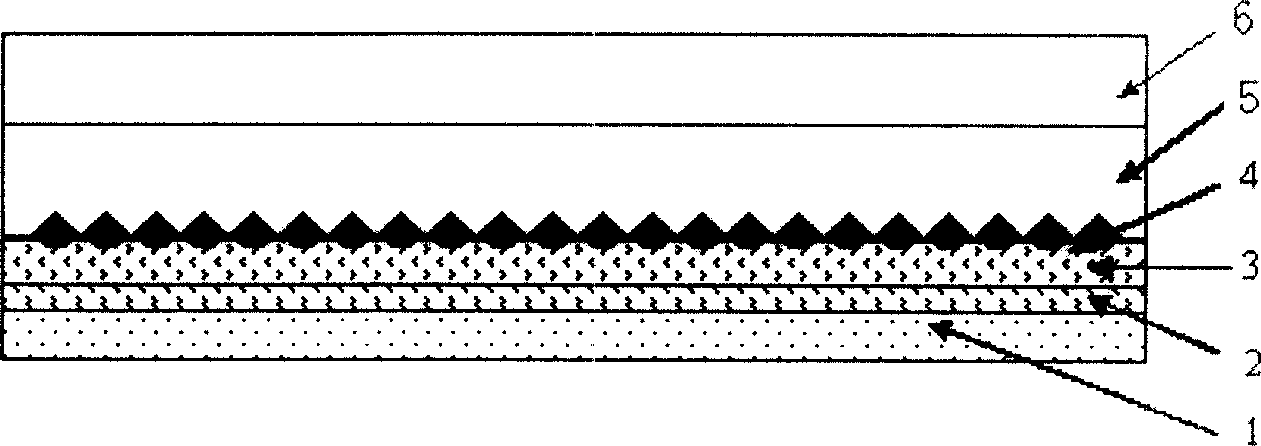

[0046] Such as figure 1 Shown, a kind of paving method (the pavement method of orthotropic steel box girder deck) that prevents the asphalt concrete of steel box girder deck from moving, comprises the following steps:

[0047] 1) The upper surface of the steel box girder bridge deck steel plate 1 is subjected to sandblasting and derusting treatment, the cleanliness reaches Sa2.5 level, the roughness Ry reaches 50 μm, and the surface dust and sundries are removed;

[0048] 2) Paving anti-rust layer 2: Spray a layer of 0.5mm thick high-temperature-resistant HBW high-strength interface glue on the upper surface of the steel plate;

[0049] 3) Paving waterproof bonding layer 3: After the high-temperature-resistant HBW high-strength interface adhesive of the anti-rust layer is completely cured, spray a layer of high-temperature-resistant HBW high-strength interface adhesive with a thickness of 2 mm, and spray it with a thickness of 3.0 before curing. kg / m 2 Evenly spread a layer of...

Embodiment 2

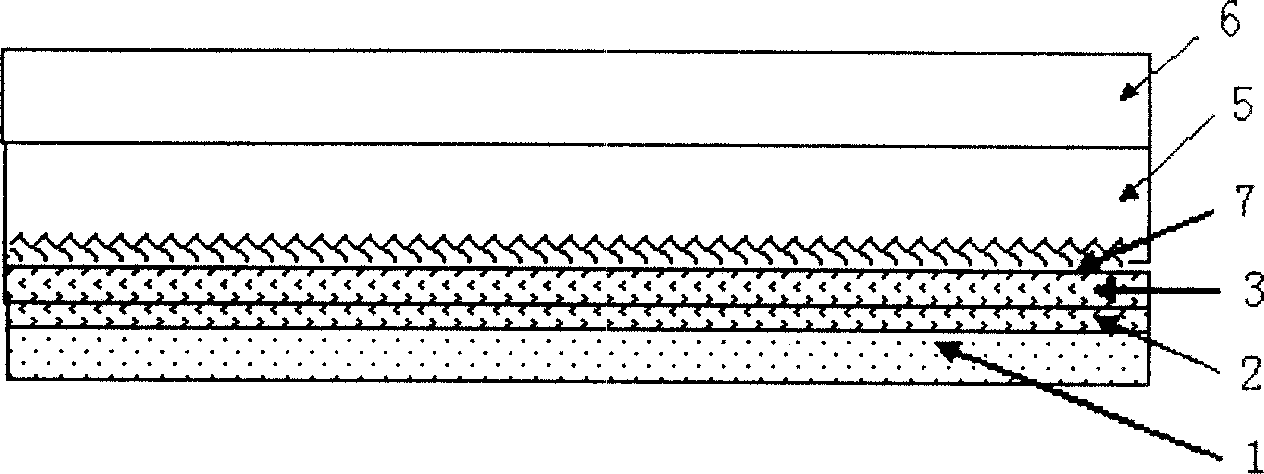

[0060] A kind of paving method (the pavement method of orthotropic steel box girder deck) that prevents the asphalt concrete of steel box girder deck from moving, is characterized in that comprising the steps:

[0061] 1) The upper surface of the steel box girder deck steel plate is subjected to sandblasting and derusting treatment, the cleanliness reaches Sa2.5 level, the roughness Ry reaches 60μm, and the surface dust and sundries are removed;

[0062] 2) Spray a layer of 1.0mm thick high-temperature-resistant HBW high-strength interface glue on the upper surface of the steel plate as an anti-rust layer;

[0063] 3) Paving the waterproof adhesive layer: After the high-temperature-resistant HBW high-strength interface adhesive of the anti-rust layer is completely cured, spray a layer of high-temperature-resistant HBW high-strength interface adhesive with a thickness of 2.5 mm, and spray it with a thickness of 5.0 before curing. kg / m 2 Evenly spread a layer of basalt particle...

Embodiment 3

[0074] A kind of paving method (the pavement method of orthotropic steel box girder deck) that prevents the asphalt concrete of steel box girder deck from moving, is characterized in that comprising the steps:

[0075] 1) The upper surface of the steel box girder bridge deck steel plate is subjected to sandblasting and derusting treatment, the cleanliness reaches Sa2.5 level, the roughness Ry reaches 70μm, and the surface dust and sundries are removed;

[0076] 2) Spray a layer of 1.5mm thick high-temperature-resistant HBW high-strength interface glue on the upper surface of the steel plate as an anti-rust layer;

[0077] 3) Paving the waterproof bonding layer: After the high-temperature-resistant HBW high-strength interface adhesive of the anti-rust layer is completely cured, spray a layer of high-temperature-resistant HBW high-strength interface adhesive with a thickness of 3mm, and use 4.0kg / m 2 Evenly spread a layer of basalt particles with a particle size of 2.36-4.75mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com