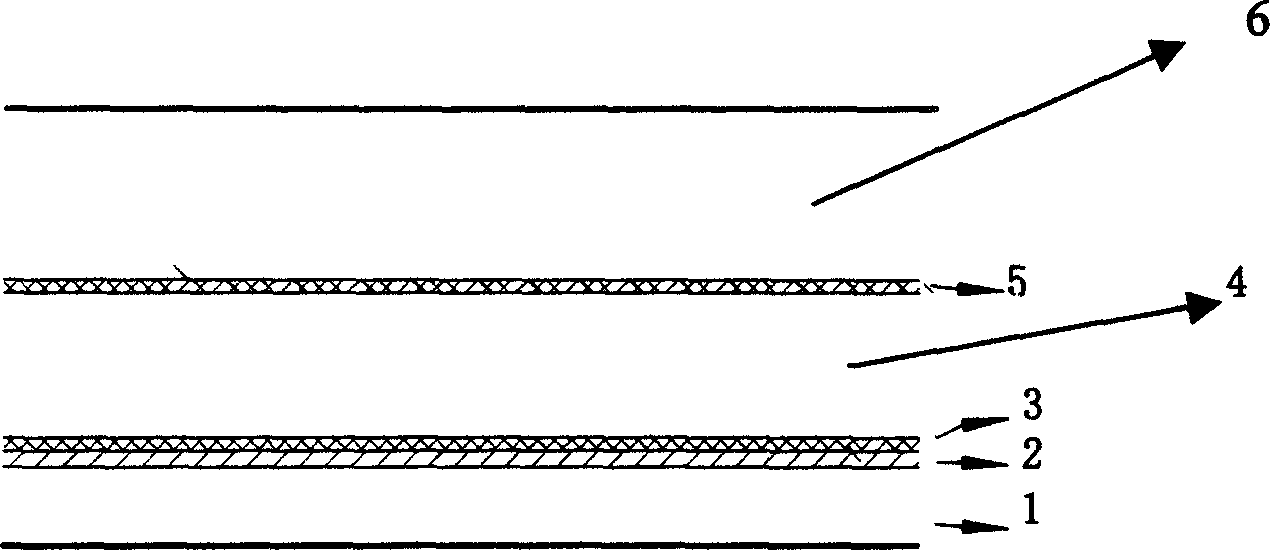

Structure of felting bridge floor made from steel box girder in large span

A bridge deck pavement and steel box girder technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems that endanger the safety of high-speed driving and affect the service life of steel bridge decks, achieve small overall modulus, and improve high temperature stability Good performance and anti-fatigue performance, strong deformation adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

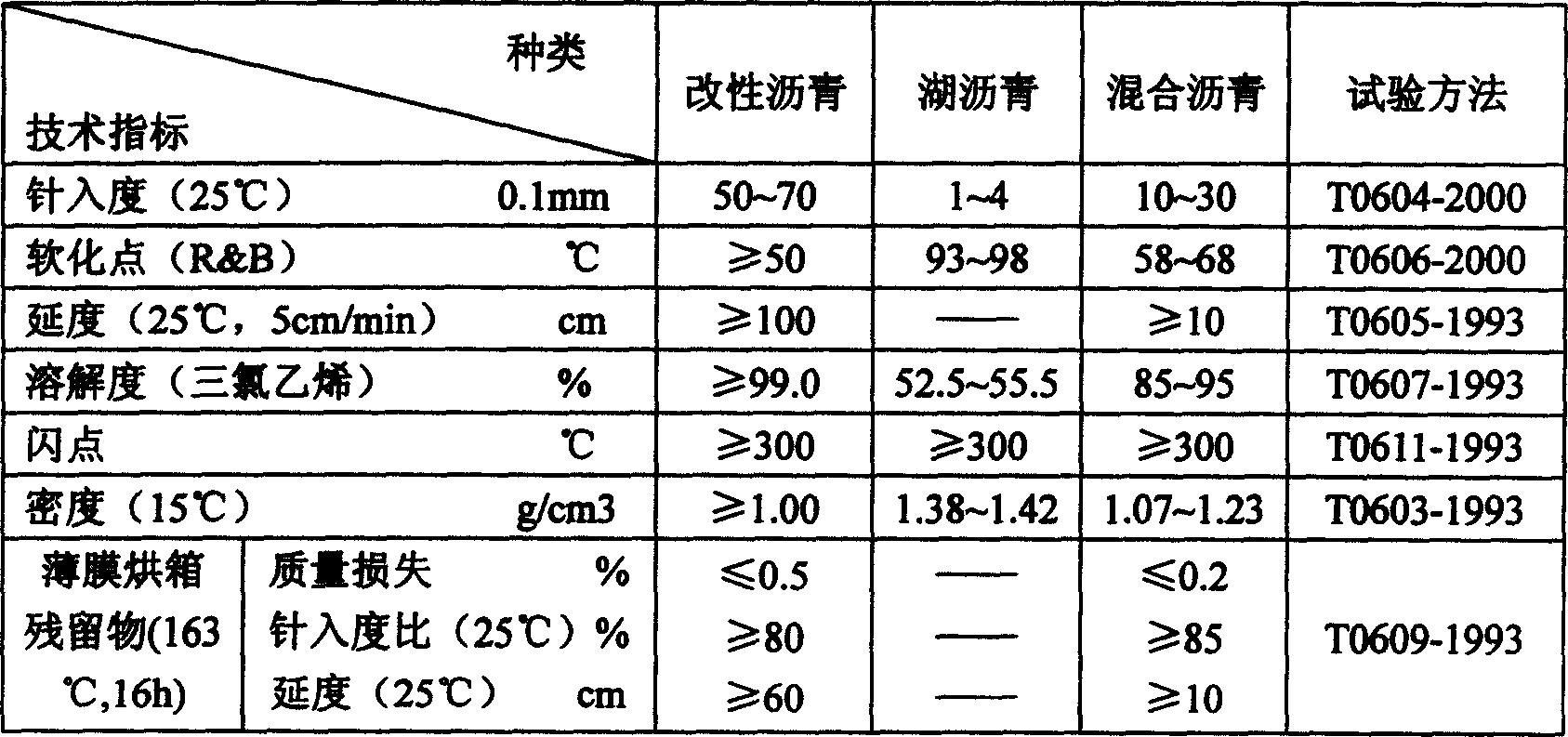

[0024] Epoxy asphalt binder consists of component A (epoxy resin) and component B v (asphalt) consists of two parts. The technical requirements of the two components are as follows.

[0025] technical indicators

skills requirement

experiment method

Viscosity (25℃) / cP

100~160

ASTM D 445

Epoxy Equivalent (grams of material containing 1 gram of epoxy)

185~192

ASTM D 1652

Color / Gardner (Gardner)

≤4

ASTM D 1544

Moisture content / %

≤0.05

ASTM D 1744

Flash point / °C

≥200

ASTM D92

1.16~1.17

ASTM D 1475

Exterior

transparent amber

visually

[0026] technical indicators

skills requirement

experiment method

Acid value (KOH per gram) / mg

40~60

ASTM D664

Flash point (Cleveland open cup) / ℃

≥200

ASTM D92

Moisture content / %

≤0.05

ASTM D95

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com