Concrete box girder bridge widening and reinforced structure and construction method thereof

A concrete box girder and reinforcement structure technology, applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems of unable to restrain the occurrence and development of oblique cracks in the web, increase the self-weight, and construction difficulties, so as to avoid damage to the natural environment and adverse social impact, reducing lateral control stress, simple and convenient construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In this embodiment, the original box girder bridge is used for expressways and is divided into two parallel bridges.

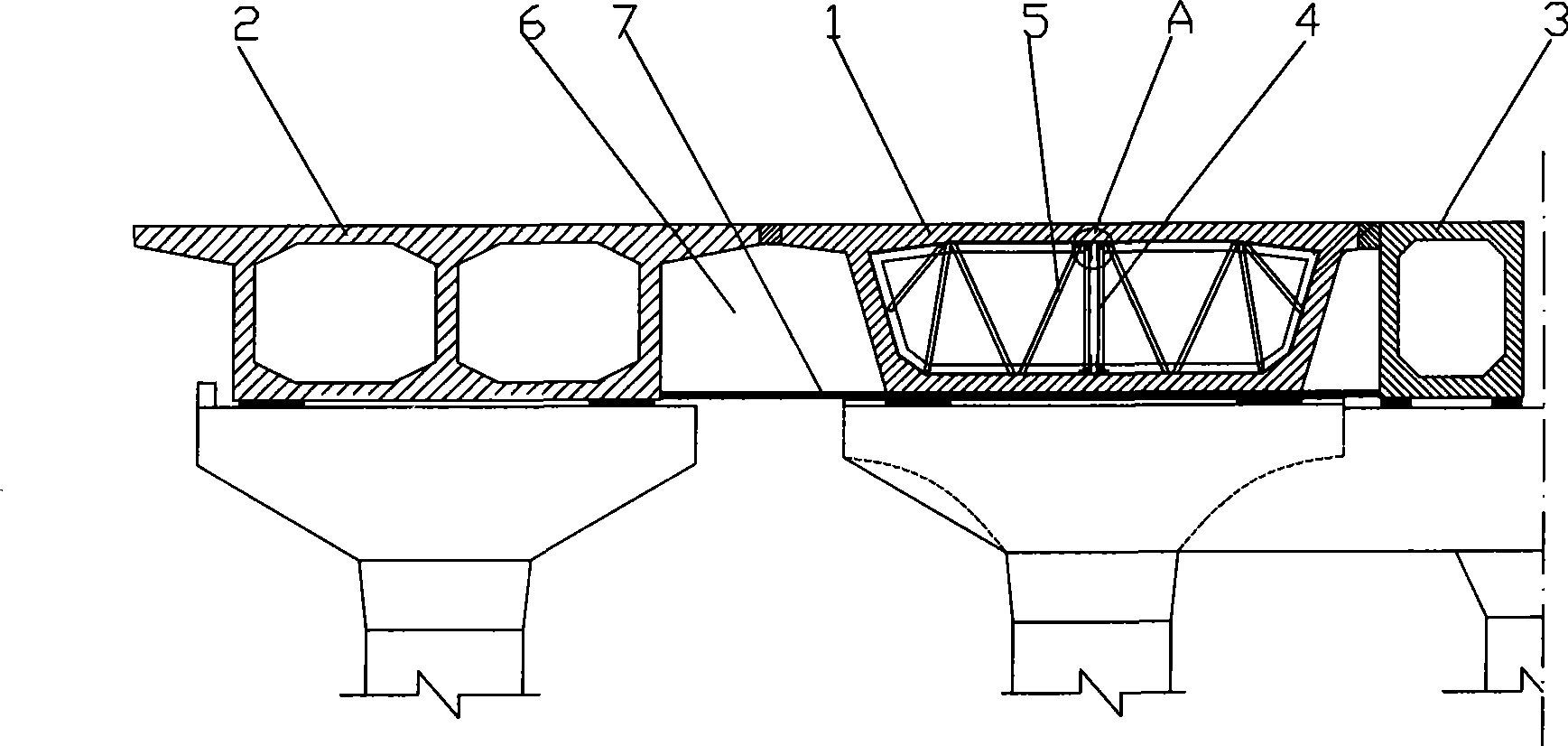

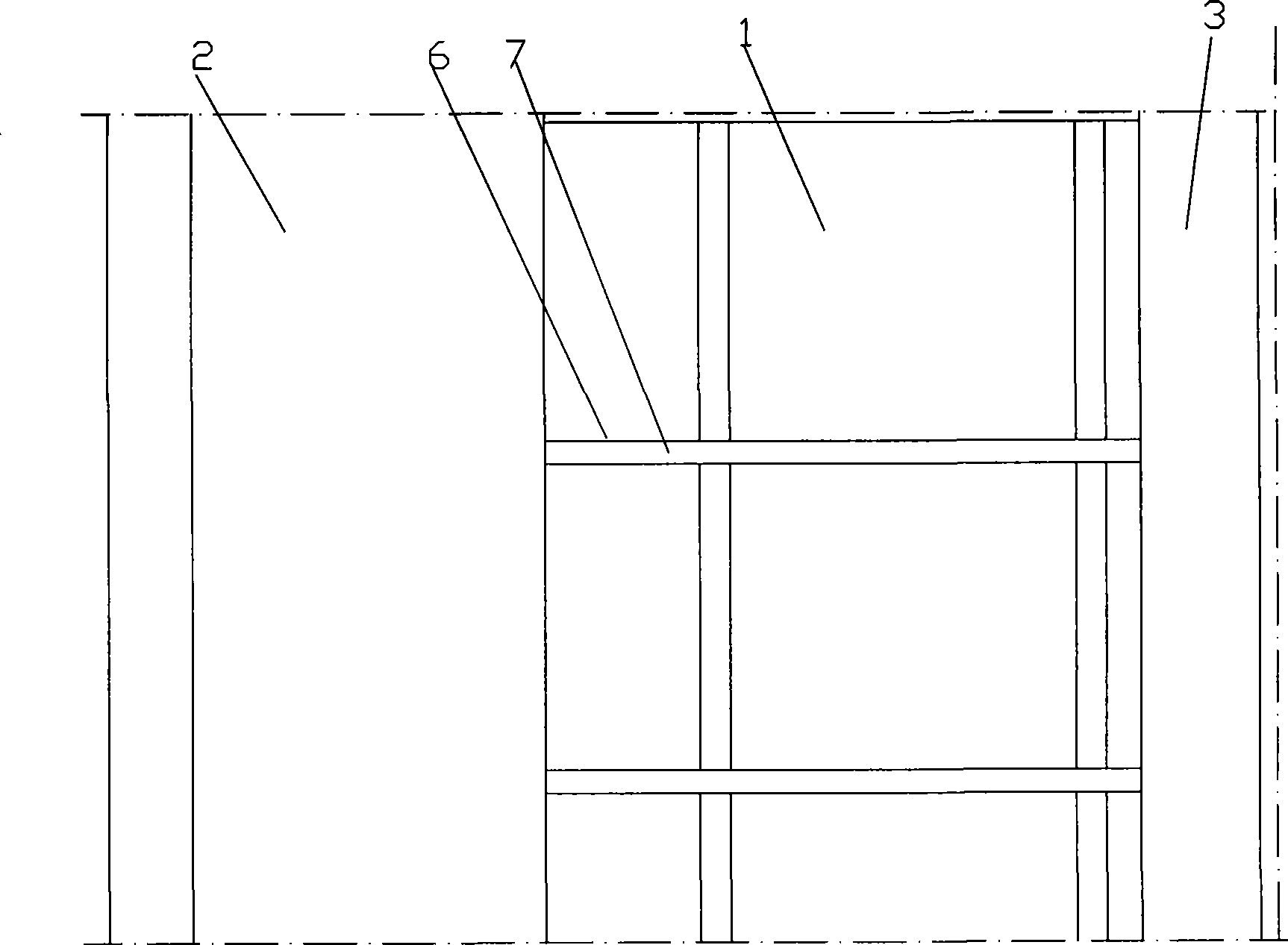

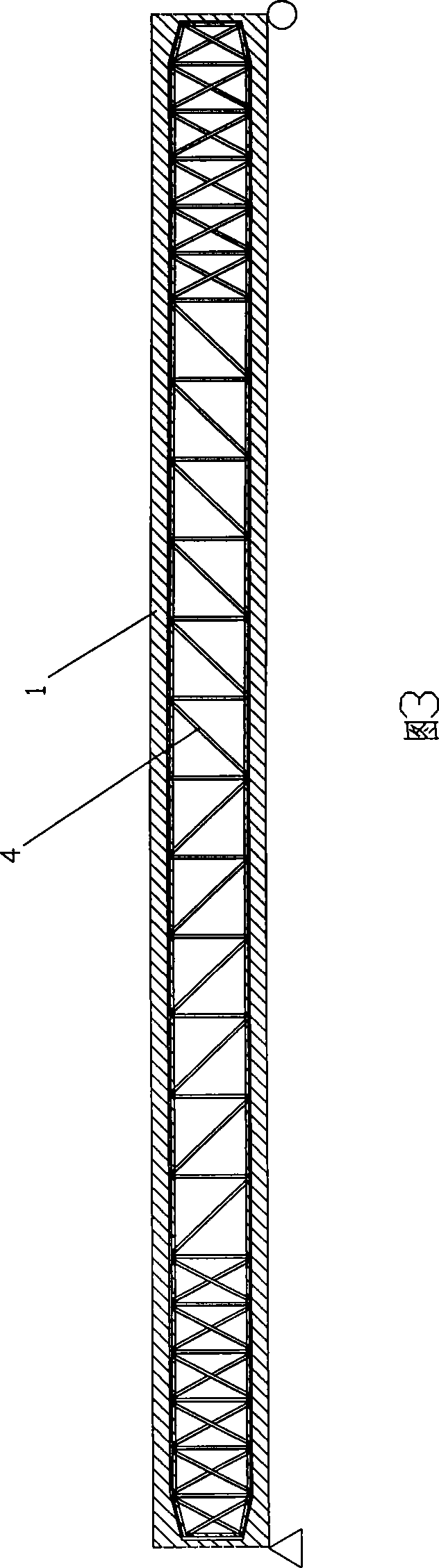

[0029] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is the bottom view of the new box girder and the box girder of the original box girder bridge. Figure 3 is a schematic diagram of the longitudinal steel truss structure, and Figure 4 is a schematic layout diagram of the longitudinal steel truss structure and the horizontal steel truss structure. Figure 5 for figure 1 Enlarged view at A, the widened and reinforced concrete box girder bridge structure of this embodiment includes new box girder I2 and new box girder II3 parallel to the original box girder bridge 1 and located on both sides of the original box girder bridge 1, and the wings of the new box girder I2 The flange and the flange of the new box girder II3 are rigidly connected with the box girder flange of the original box girder bridge 1 by casti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com