CNC (Computerized Numerical Control) automatic internal grinding machine for bearing ring

An internal grinding machine and bearing ring technology, which is applied in the direction of grinding machines, grinding machine parts, and machine tools designed for grinding the rotating surface of workpieces, etc. Small and other problems, to achieve the effect of easy control of size dispersion, good accuracy retention, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

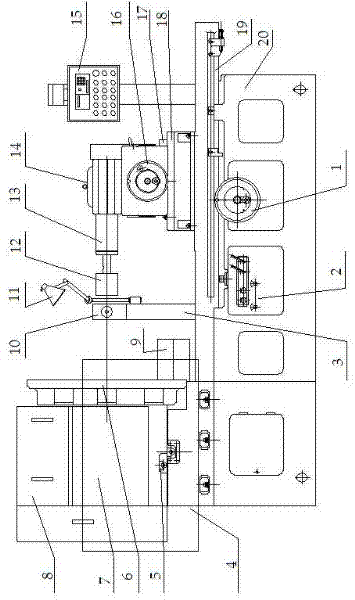

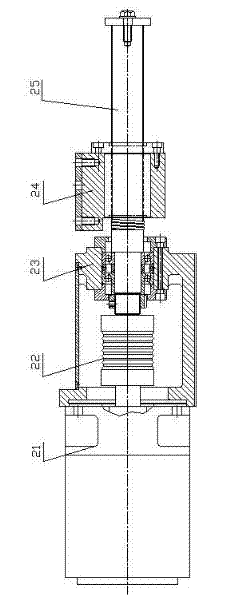

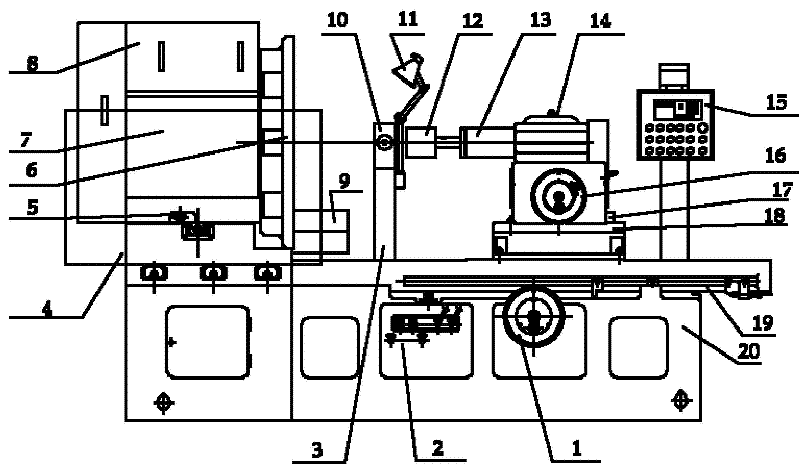

[0017] The structure of the CNC automatic bearing ring cylindrical grinding machine of the present invention is as follows: figure 1 As shown, it includes a bed 20, a reciprocating table 19, a grinding wheel shaft assembly, a workpiece shaft box 7, a grinding wheel dresser 10, a longitudinal feed transmission mechanism, a lateral feed transmission mechanism, a cooling system, a hydraulic lubrication system, and a CNC control system. Main engine and operation panel 15, electric control system, described reciprocating table 19, workpiece shaft box 7 and grinding wheel dresser 10 are installed on the bed 20, and the grinding wheel shaft assembly is installed on the reciprocating work table 19, on the grinding wheel shaft assembly There are transverse feed handwheels 16 and grating scales; the longitudinal feed transmission mechanism and hydraulic lubrication system are installed inside the bed 20, the cooling system and electrical control system are installed on the rear side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com