Novel winding type energy accumulator

An accumulator, winding technology, applied in mechanical equipment and other directions, can solve problems such as affecting the normal use of piston accumulators, shortening the gas supplementary pressure cycle, and reducing system reliability, reducing impact, weight, and reducing The effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

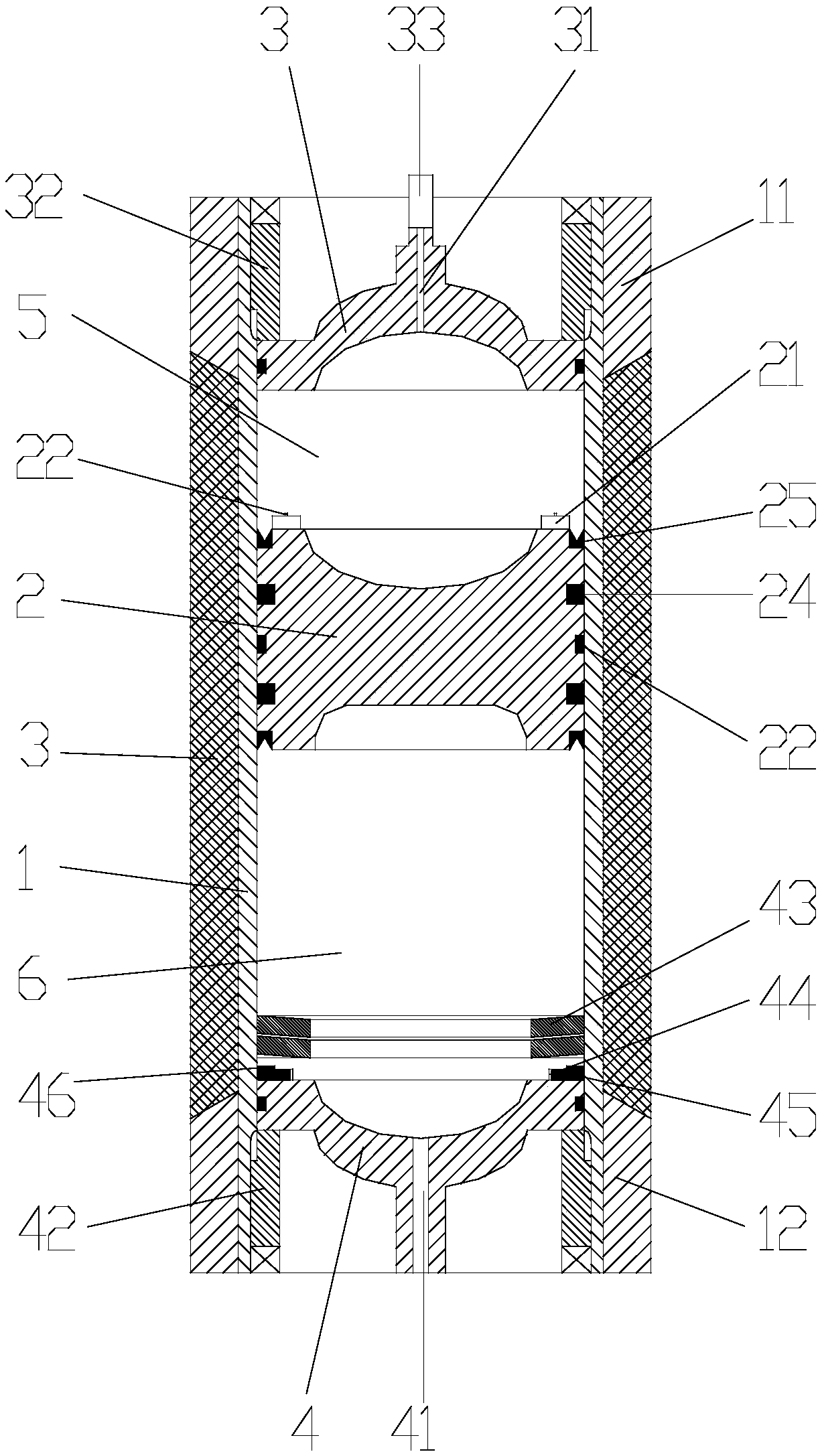

[0019] The purpose of this embodiment is to provide a novel winding accumulator, such as figure 1 As shown, the accumulator includes an accumulator cylinder 1 made of thin-walled aluminum alloy, a piston 2 disposed in the cylinder, a gas cap 3 disposed above the cylinder, and an end cap 4 disposed below the cylinder The sections of the gas cover 3 and the end cover 4 are elliptical structures; the piston 2 divides the cylinder body 1 into an upper air cavity 5 and an oil cavity 6 below, and the gas cover 3 is provided with an air cavity The end cover 4 is provided with an oil port 41 communicating with the oil chamber; the piston 2 slides freely in the barrel 1 under the pressure fluctuations of the oil chamber 6 and the air chamber 5, and its initial pressure com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com