Protection against the oxidation of composite material parts containing carbon and parts thus protected

A composite material, anti-oxidation technology, applied in mechanical equipment, friction linings, gear transmission mechanisms, etc., can solve problems such as complex anti-oxidation protection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Samples of C / C composites were prepared as follows.

[0058] The stack is formed by stacking unidirectional fiber sheets of carbon precursor fibers (pre-oxidized polyacrylonitrile) in different directions and bonded together by needling. The resulting fiber preforms were subjected to heat treatment to convert the precursors to carbon by pyrolysis, and then reinforced with the pyrolyzed carbon matrix by chemical vapor infiltration. Such methods are known. Reference may be made, for example, to document US 4 790 052 . The blocks of C / C material obtained by this method were cut into samples in the form of cuboid blocks having dimensions of 20 mm x 25 mm x 8 mm.

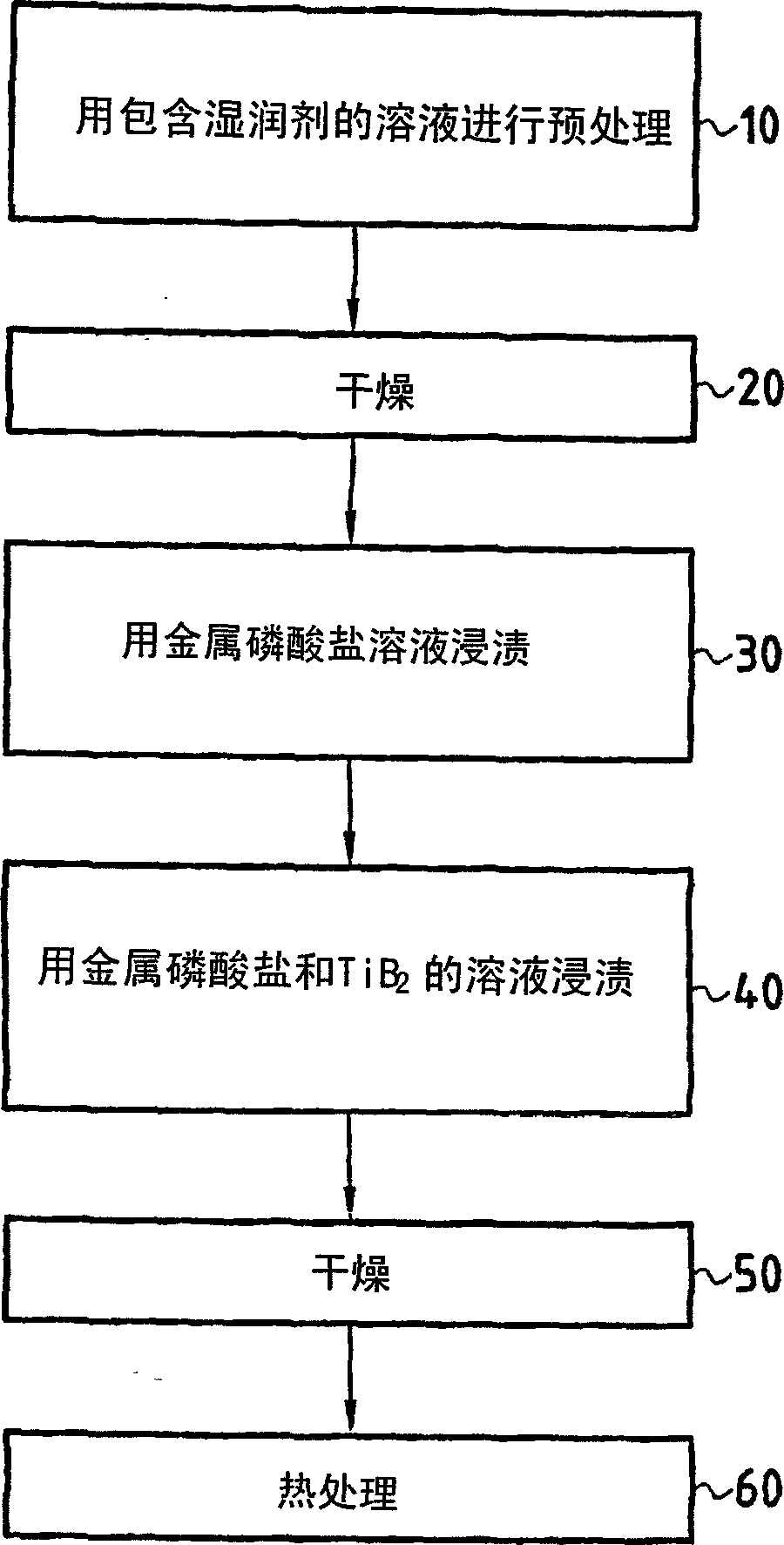

[0059] Some samples were provided with oxidation protection by a method comprising the following steps:

[0060] a) Pretreatment of the sample by immersing the sample in an ultrasonic vessel containing an aqueous solution of a wetting agent based on polyethoxy isononyl available under the trade name "Marlophen ...

Embodiment 2

[0086] As in the procedure in Example 1, but in step c), using a compound containing 32% by weight of Al(H 2 PO 4 ) 3 , 56% ZrB 2 , and the impregnating composition remaining as water.

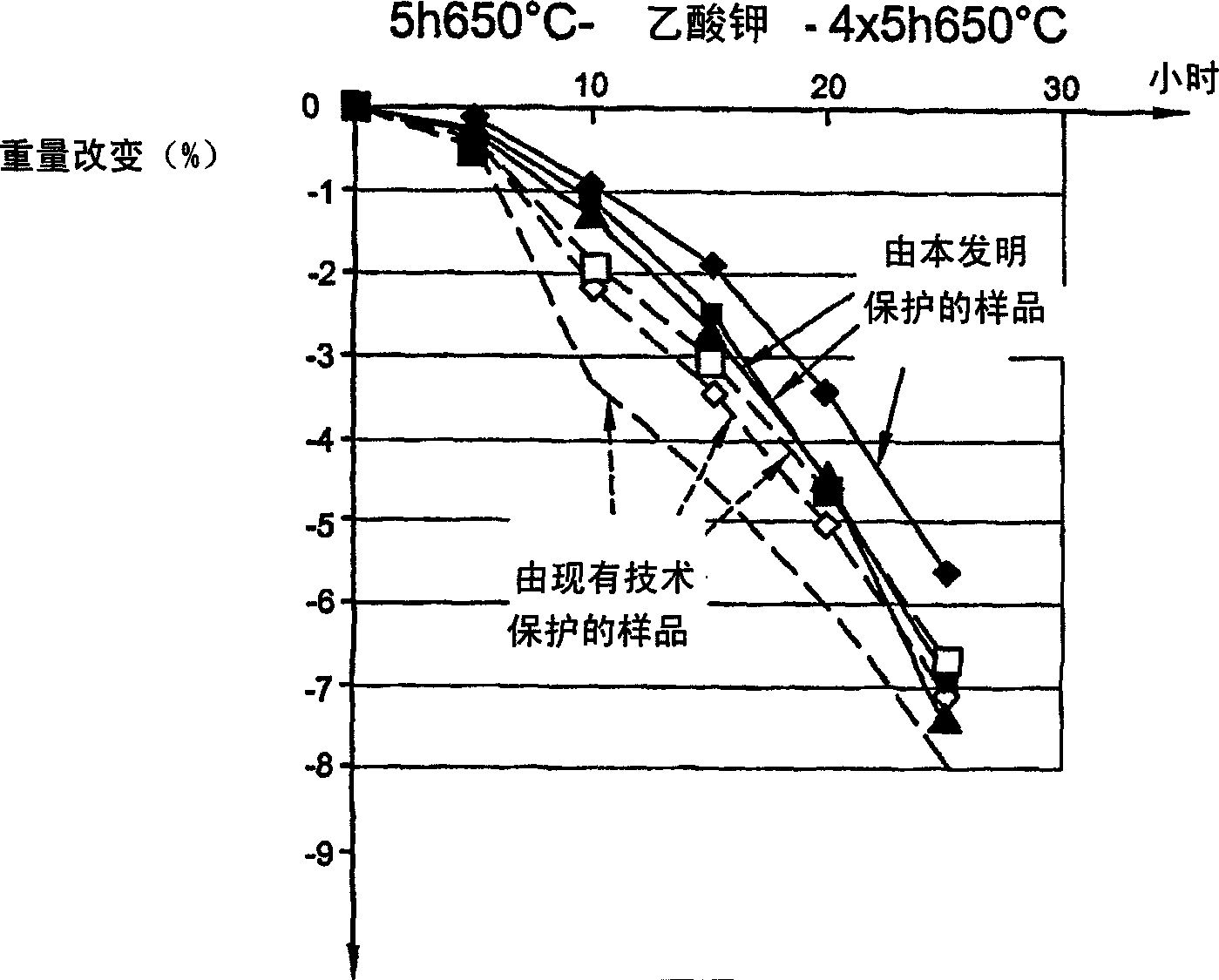

[0087] Some samples protected using the method of example 2 were subjected to the same oxidation test as test V) above.

[0088] Table II shows the relative weight loss (percentage relative to the initial weight) measured on each sample after carrying out the test. For comparison, Table II also shows the weight loss observed in the same oxidation tests carried out on samples protected according to Example 1 and samples protected according to the reference.

[0089] Table II

[0090] sample

[0091] The results show that the use of ZrB in impregnation compositions 2 instead of TiB 2 This results in a significant reduction in effectiveness in oxidation protection similar to that observed in samples protected according to the prior art.

Embodiment 3

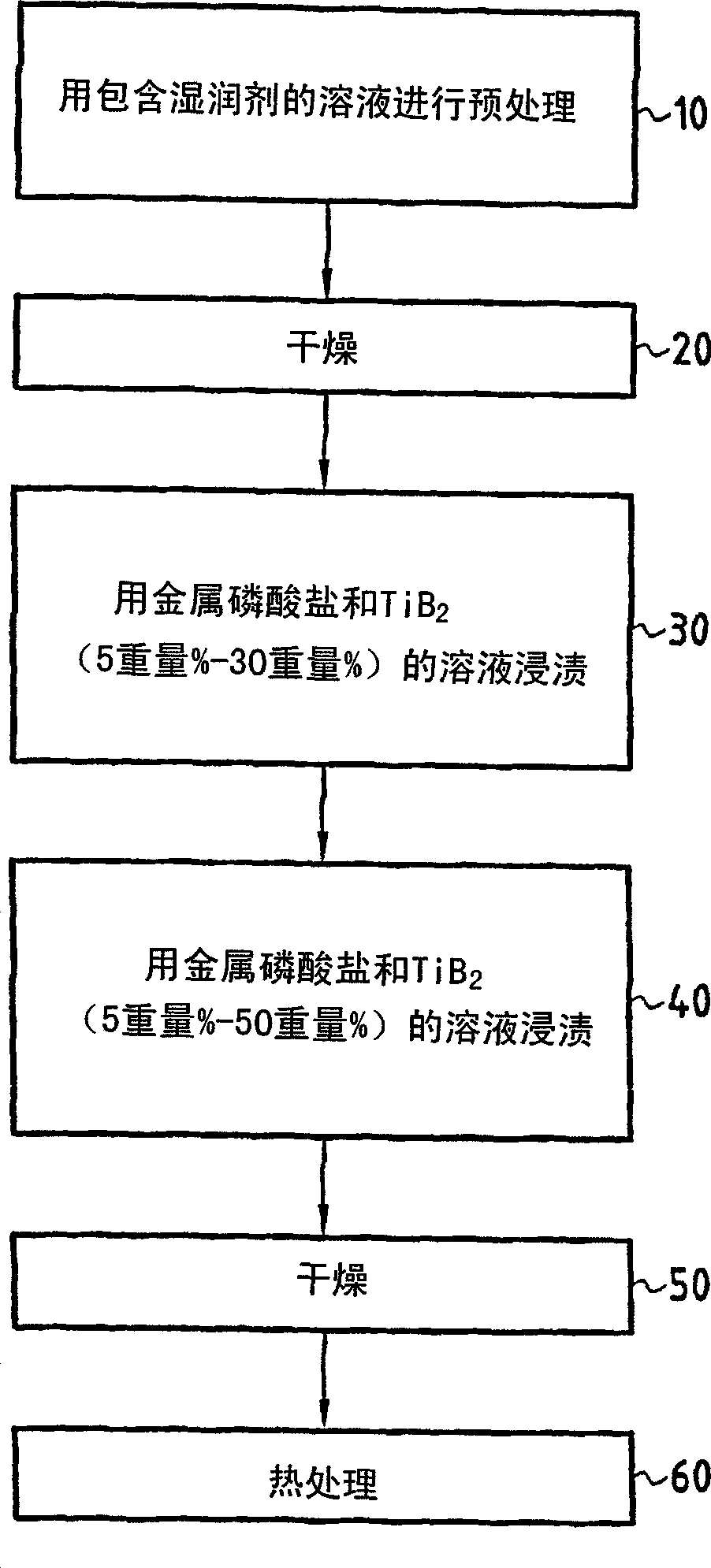

[0093] Using samples made of the same type of C / C composite as in Example 1, they were protected against oxidation by adapting the method described in Example 1 as follows:

[0094] · In step b), use contains by weight: 44% Al(H 2 PO 4 ) 3 , 14% of TiB in powder form with an average particle size of about 10 μm 2 , and the impregnating composition remaining as water; and

[0095] · In step c), use contains by weight: 34% Al(H 2 PO 4 ) 3 and 39% of TiB in powder form with an average particle size of about 10 μm 2 impregnation composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com