Ceramic matrix composite slender thin-wall pipe fitting preparation method, ceramic matrix composite slender thin-wall pipe fitting based on method and application of pipe fitting

A composite material and ceramic-based technology, which is applied in the field of ceramic-based composite slender thin-walled pipe fittings and their preparation, can solve the problem of large residual porosity, inability to achieve ultra-long-diameter ratio, and inability to meet external and in-stack assessment requirements, etc. problem, to achieve the effect of economical efficiency, low cost and improved air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

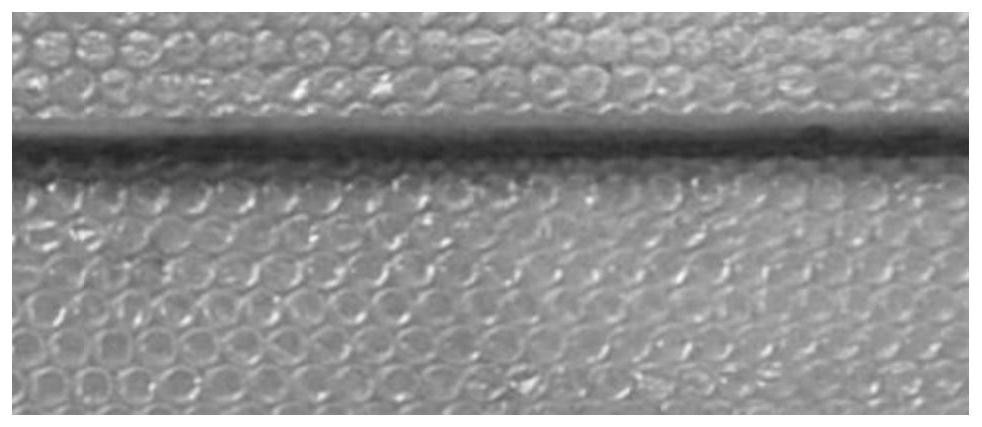

[0036] This example is for SiC f The thickness of the middle layer of SiC composite material is 0.7mm, the thickness of the inner layer of SiC ceramic is 50±10μm, the thickness of the outer layer of SiC ceramic is 50±10μm, the length is 300mm, and the outer diameter is 9.50mm.f / SiC tube preparation.

[0037] Choose a suitable outer diameter, 300mm long stainless steel tubular or rod-shaped mandrel, and wind a 1mm thick paper layer (centrifugal paper or kraft paper, etc.) and 1.05mm thick SiC fiber cloth to form a 300mm long tubular fiber prefabricated body; the tubular fiber The preform is placed in the graphite outer mold (holes with a diameter of 2-3mm are evenly distributed on the mold wall of the graphite outer mold), and then the mandrel is extracted, and a 150 ± 20nm thick fiber is prepared on the tubular fiber preform by chemical vapor infiltration. Pyrolyze the carbon interface to form a tubular fiber preform containing the interface; remove the carbonized paper dust...

Embodiment 2

[0044] This example is for C f / The thickness of the middle layer of SiC composite material is 2mm, the thickness of the inner layer of SiC ceramic is 50±10μm, the thickness of the outer layer of SiC ceramic is 50±10μm, the length is 950mm, and the outer diameter is 29.00mm. f / SiC tube preparation.

[0045] Select a suitable outer diameter, 950mm long aluminum alloy tubular mandrel, and wrap 1.5mm thick centrifugal paper and 2.5mm thick SiC fiber cloth successively to form a 950mm long tubular fiber preform; place the tubular fiber preform in the graphite outer mold (the uniform diameter is 2-3mm hole on the mold wall of this graphite outer mold), then the mandrel is extracted out, adopts the chemical vapor infiltration method to prepare the pyrolytic carbon interface of 150 ± 20nm thickness on the tubular fiber prefabricated body, forms containing Tubular fiber preform at the interface; remove the carbonized centrifugal paper in the core of the fiber preform, and use trich...

Embodiment 3

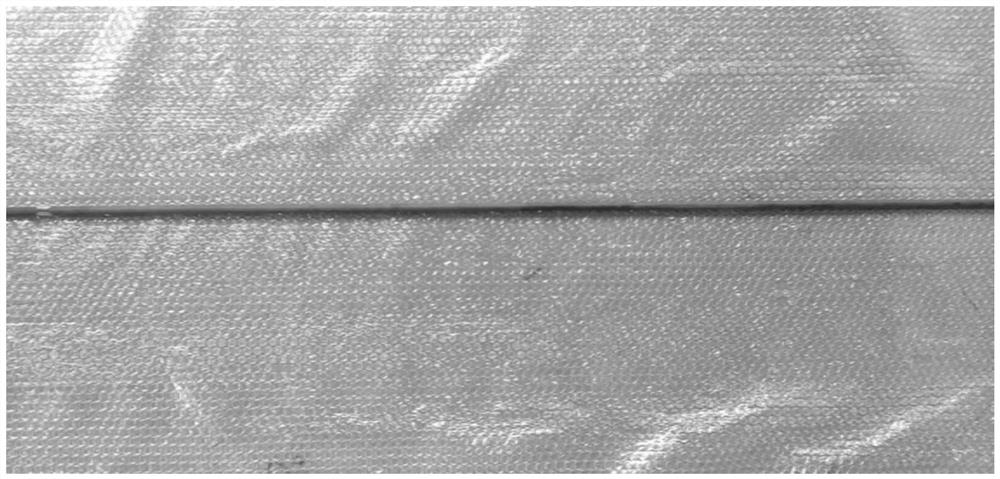

[0052] SiC f The thickness of the middle layer of SiC composite material is 0.7mm, the thickness of the inner layer of SiC ceramic is 50±10μm, the thickness of the outer layer of SiC ceramic is 50±10μm, the length is 1200mm, and the outer diameter is 9.50mm. f / SiC tube preparation. .

[0053] Choose a suitable outer diameter, 1200mm long aluminum alloy rod-shaped mandrel is wound successively with 1mm thick centrifugal paper and 1.05mm thick SiC fiber cloth to form a 1200mm long tubular fiber prefabricated body; place the tubular fiber prefabricated body in the graphite outer mold ( Holes with a diameter of 2-3mm are evenly distributed on the mold wall of the graphite outer mold), and then the mandrel is pulled out, and a pyrolytic carbon interface with a thickness of 150 ± 20nm is prepared on the tubular fiber preform by chemical vapor infiltration to form an interface containing Tubular fiber prefabricated body; remove the carbonized centrifugal paper in the core of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com