Method for preparing Cu/MoCu/Cu three-layer composite plate blank

A technology of composite slab and composite plate, which is applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of high production cost, long preparation process, complicated procedures, etc., and achieves low processing cost, The effect of short process route and reduced residual porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The layer thickness ratio of the present embodiment Cu / MoCu / Cu three-layer composite slab is 1: 1: 1; The mass percent content of copper in the MoCu intermediate layer of the present embodiment Cu / MoCu / Cu three-layer composite slab is 30 %, and the balance is molybdenum.

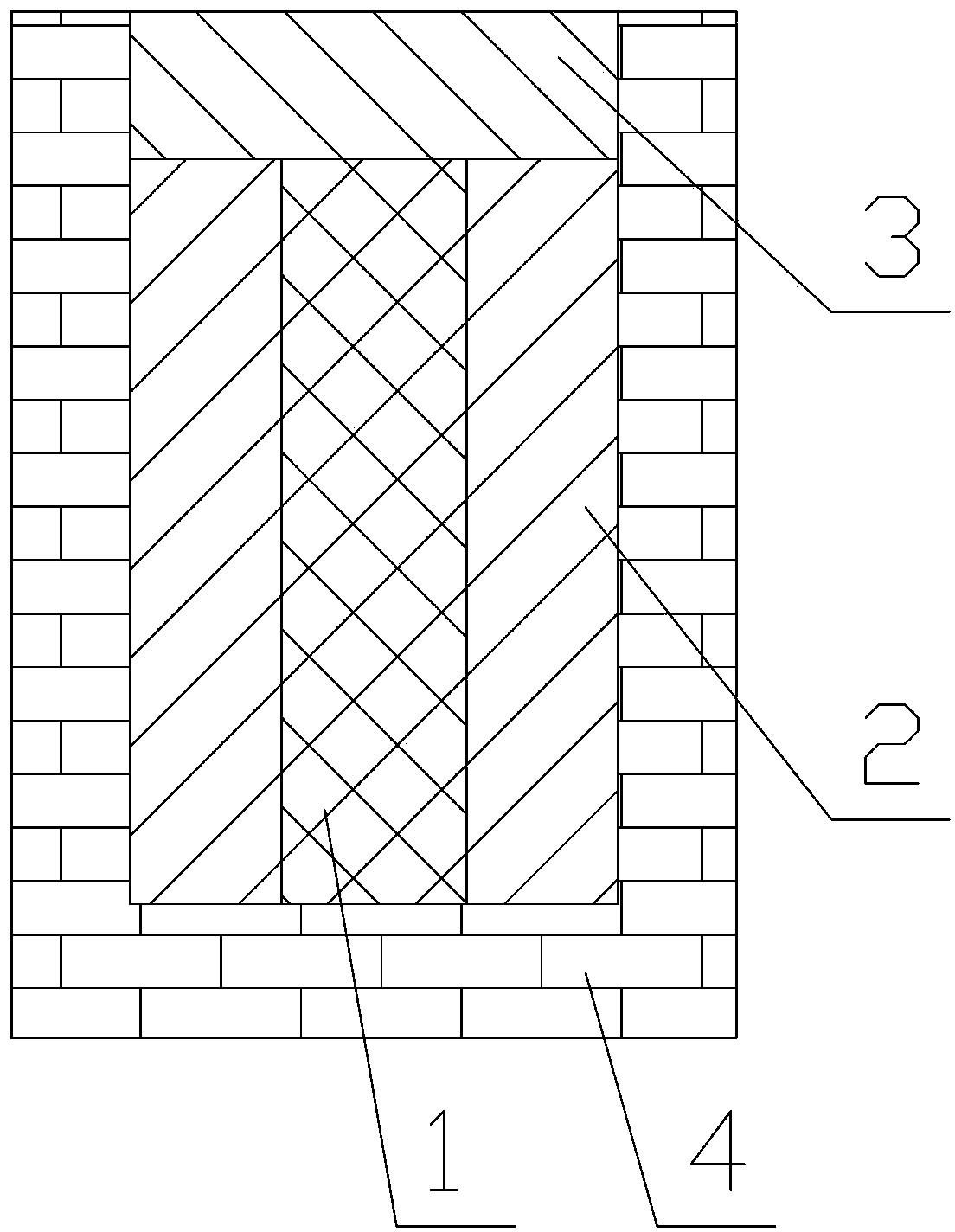

[0032] to combine figure 1 , the preparation method of the present embodiment Cu / MoCu / Cu three-layer composite slab comprises the following steps:

[0033] Step 1, uniformly mixing molybdenum powder and copper powder to obtain molybdenum-based composite powder; the mass percentage of copper powder in the molybdenum-based composite powder is 1%, and the balance is molybdenum powder;

[0034] Step 2, using a hydraulic press to press the molybdenum-based composite powder described in step 1 into a molybdenum-based composite slab 1 with a length of 160mm, a width of 90mm, and a thickness of 7mm; the porosity of the molybdenum-based composite slab 1 is 30% ;

[0035] Step 3. Lay the molybdenum-based com...

Embodiment 2

[0038] The layer thickness ratio of the present embodiment Cu / MoCu / Cu three-layer composite slab is 1.5: 1: 1.5; The mass percent content of copper in the MoCu intermediate layer of the present embodiment Cu / MoCu / Cu three-layer composite slab is 20 %, and the balance is molybdenum.

[0039] combine figure 1 , the preparation method of the present embodiment Cu / MoCu / Cu three-layer composite slab comprises the following steps:

[0040] Step 1, uniformly mixing molybdenum powder and copper powder to obtain molybdenum-based composite powder; the mass percentage of copper powder in the molybdenum-based composite powder is 1%, and the balance is molybdenum powder;

[0041] Step 2, using a hydraulic press to press the molybdenum-based composite powder described in step 1 into a molybdenum-based composite slab 1 with a length of 200mm, a width of 100mm, and a thickness of 6mm; the porosity of the molybdenum-based composite slab 1 is 20% ;

[0042] Step 3. Lay the molybdenum-based com...

Embodiment 3

[0045] The layer thickness ratio of the present embodiment Cu / MoCu / Cu three-layer composite slab is 1: 2: 1; The mass percent content of copper in the MoCu intermediate layer of the present embodiment Cu / MoCu / Cu three-layer composite slab is 25 %, and the balance is molybdenum.

[0046] combine figure 1 , the preparation method of the present embodiment Cu / MoCu / Cu three-layer composite slab comprises the following steps:

[0047] Step 1, uniformly mixing molybdenum powder and copper powder to obtain molybdenum-based composite powder; the mass percentage of copper powder in the molybdenum-based composite powder is 1.5%, and the balance is molybdenum powder;

[0048] Step 2, using a hydraulic press to press the molybdenum-based composite powder described in step 1 into a molybdenum-based composite slab 1 with a length of 150mm, a width of 100mm, and a thickness of 10mm; the porosity of the molybdenum-based composite slab 1 is 25% ;

[0049] Step 3. Lay the molybdenum-based co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com