Method for preparing fiber braided tube embedded enhanced type polymer hollow fiber microporous membrane

A technology of fiber braided tube and polymer, which is applied in the field of preparation and modification of polymer separation membrane materials, can solve the problems of introducing core fluid into the inner cavity of the braided tube, and achieve good membrane hydrophilicity, large flux and retention, and high The effect of interception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

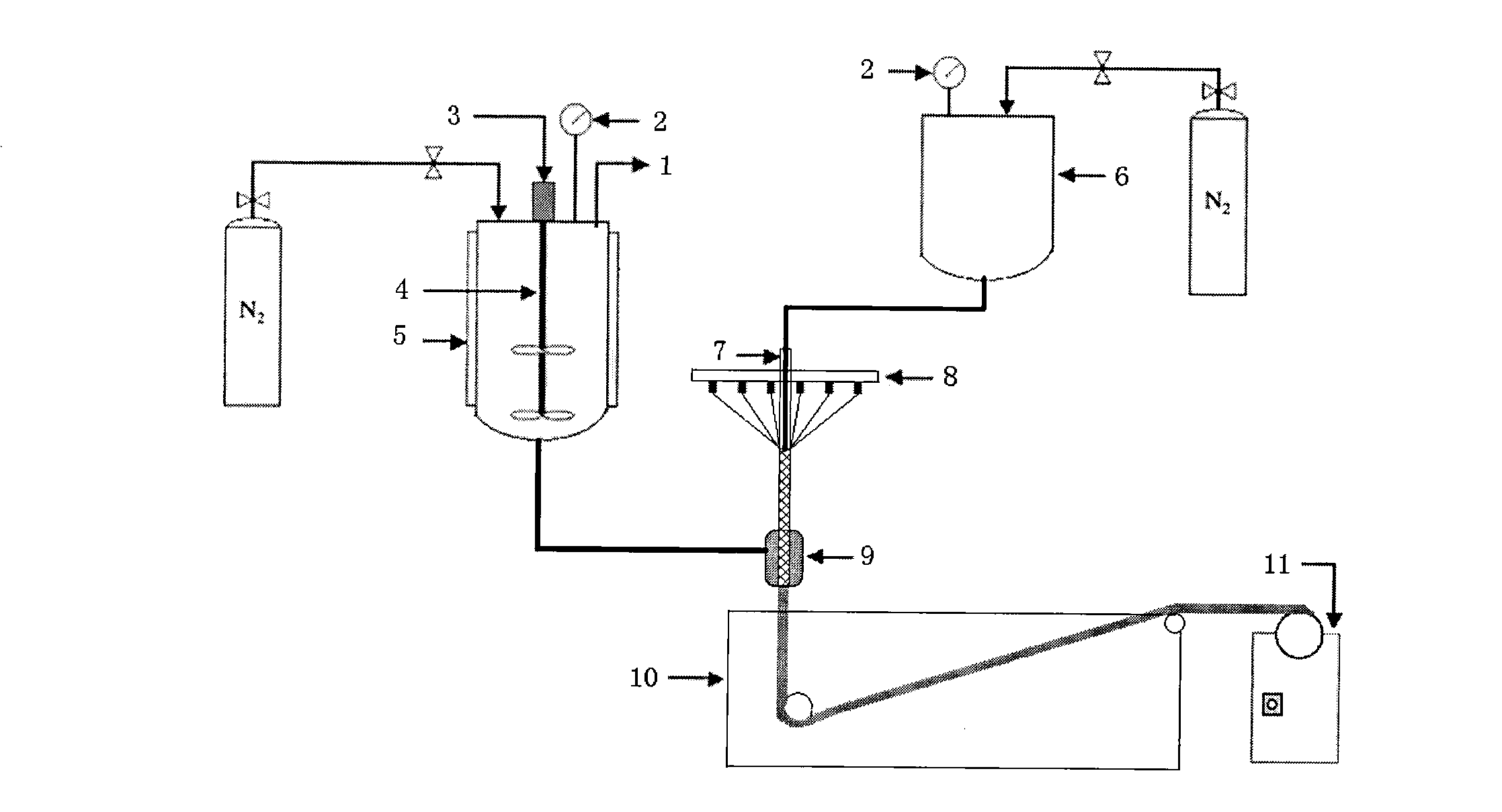

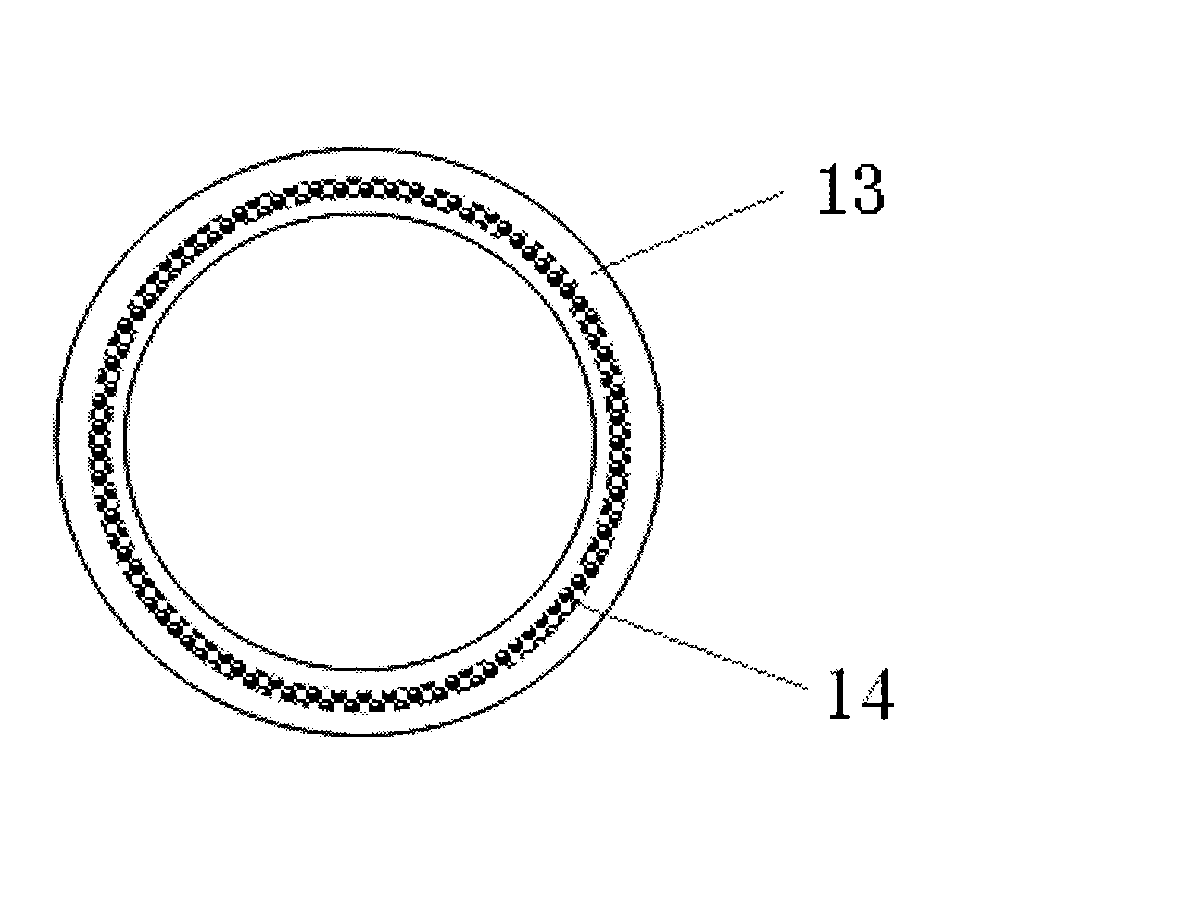

[0018] The preparation method of the fiber braided tube embedded in the reinforced polymer hollow fiber microporous membrane of the present invention comprises the following steps:

[0019] 1. Preparation of casting solution: Stir the polymer, solvent, non-solvent, and hydrophilic modifier in a reaction kettle at a temperature of 80-140°C for 12-24 hours, filter, and vacuum defoam for 12-36 hours to obtain Casting solution;

[0020] 2. Fiber braiding and co-extrusion integrated film formation: the casting liquid is extruded into the extrusion mold under the pressure of 0.1-0.4MPa; the core liquid (hollow molding liquid) is passed through the core liquid under the pressure of 0.01-0.05MPa The tube is extruded into the extrusion die by pressure; the fiber bundle on the wire frame of the braiding machine is cross-braided in a "herringbone" shape along the core liquid tube, so that the core liquid tube is fixed in the middle of the braided fiber braided tube, and the fiber braided...

Embodiment 1

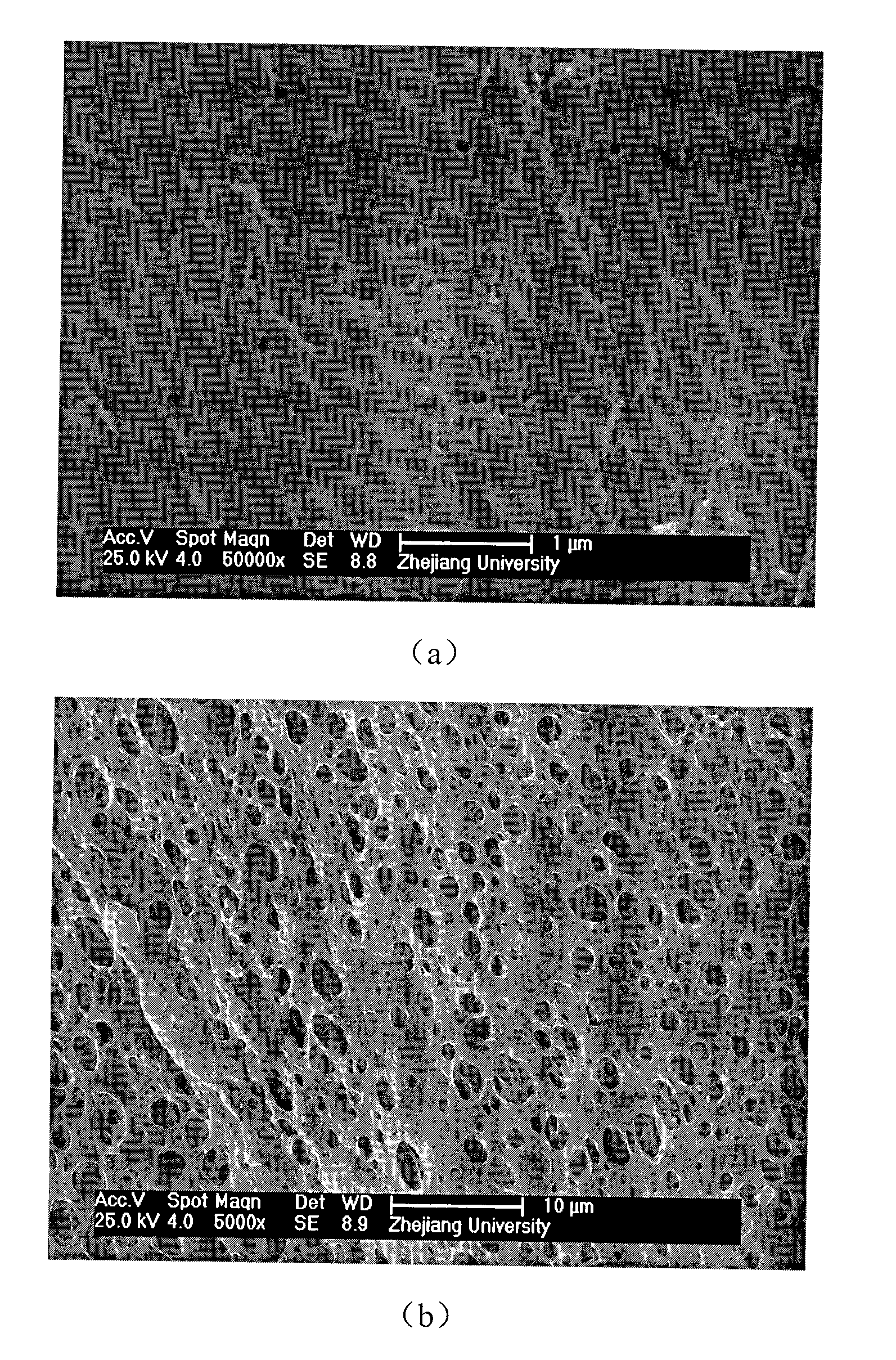

[0027] 1. Polyvinylidene fluoride (15% by weight concentration), N, N-dimethylacetamide (70% by weight concentration), polyethylene glycol 600 (10% by weight concentration), polyethylene Pyrrolidone (5% by weight concentration) was stirred in a reaction kettle at a temperature of 90° C. for 12 hours, filtered, and vacuum defoamed for 24 hours to obtain a casting solution;

[0028] 2. Under the pressure of 0.2MPa, the casting liquid is extruded into the extrusion mold by pressure; 2O is used as the core liquid under the pressure of 0.01MPa, and is extruded into the extrusion die through the core liquid tube; "" cross braiding, so that the core liquid tube is fixed in the middle of the braided fiber braided tube, driven by the friction wheel, the fiber braided tube enters the extrusion mold at a forward speed of 3m / min; the casting liquid, core liquid , The fiber braided tube is co-extruded through an extrusion die, immersed in 60°C H 2 Phase separation occurs in O, and fiber ...

Embodiment 2

[0033] The preparation steps are the same as in Example 1.

[0034]

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com