Method for preparing Ti-Si-N nanocrystalline-amorphous composite superhard coating

A nanocrystalline and hard coating technology, applied in coating, superimposed layer plating, metal material coating process, etc., can solve the problem of magnetron sputtering method with low ionization rate, poor use effect and low coating hardness and other problems, to achieve good application prospects, high ionization rate, and fast deposition rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

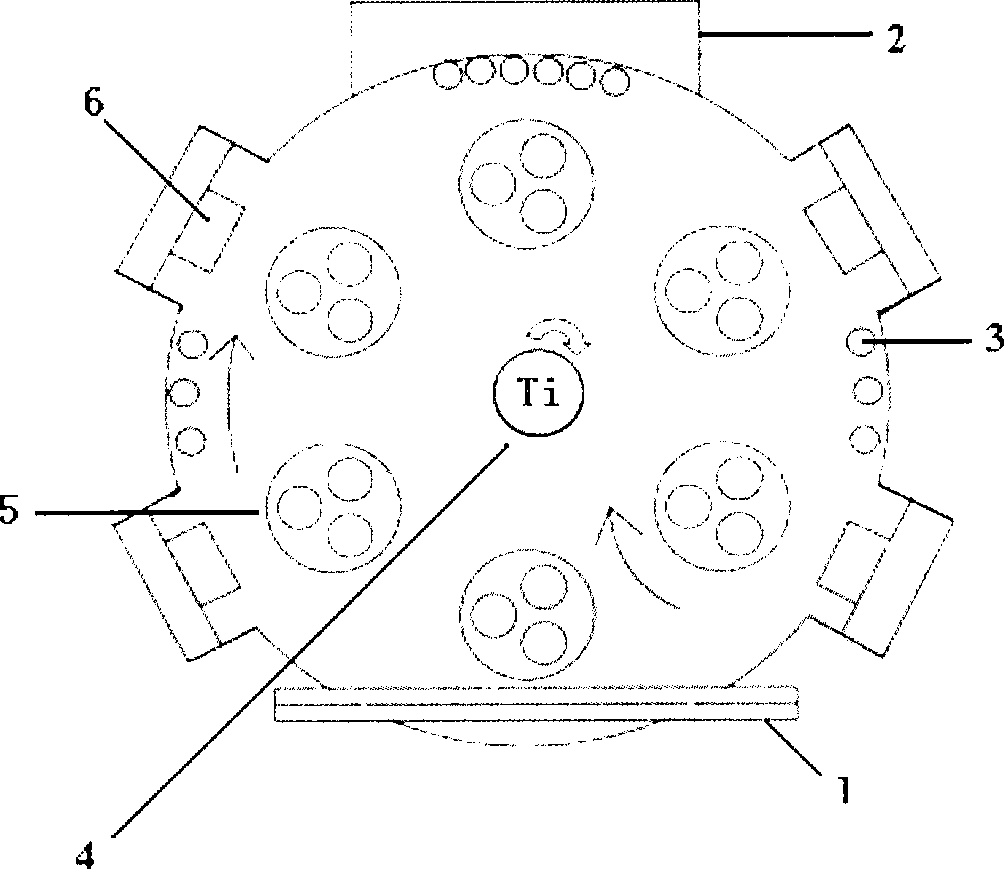

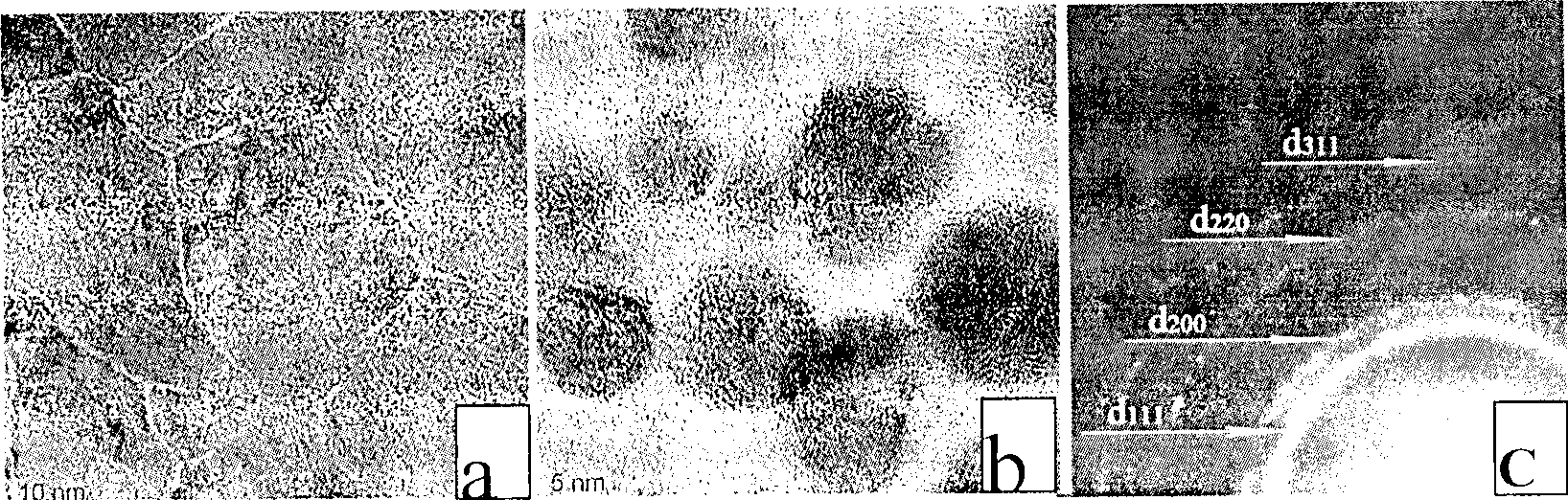

[0020] Example 1: The glow discharge cleaning of the workpiece is carried out at 400-450°C under an argon atmosphere; after the glow cleaning is completed, it is placed in a vacuum chamber, and the magnetic field is used under the conditions of 0.5Pa, negative 150V bias and 400-450°C The metal Ti transition layer is prepared by controlled metal target arc discharge, and the deposition thickness of the metal Ti transition layer is 200 nanometers; then silane and nitrogen are passed through, and the air pressure is controlled at 0.8 Pa. Ti ions evaporate from the Ti target and react with nitrogen to form TiN . Silane dissociates into Si ions and reacts with nitrogen to form Si 3 N 4 . TiN and Si under bias 3 N 4 At the same time, a film is grown on the substrate to form a Ti-Si-N nanocomposite coating. Wherein the gas flow rate of nitrogen gas is 150 sccm; the flow rate of silane gas is 250 sccm, and the SiH gas flow rate of the vacuum chamber 4 The flow of nitrogen and ni...

Embodiment 2

[0022] Example 2: The glow discharge cleaning of the workpiece is carried out at 400-450°C under an argon atmosphere; after the glow cleaning is completed, it is placed in a vacuum chamber and controlled by a magnetic field under the conditions of 1Pa, negative 200V bias voltage and 400-450°C The metal Ti transition layer was prepared by arc discharge of a metal target, and the deposition thickness of the metal Ti transition layer was 200 nanometers; then silane and nitrogen gas were introduced, and the air pressure was controlled at 1.5 Pa. Ti ions evaporated from the Ti target and reacted with nitrogen to form TiN . Silane dissociates into Si ions and reacts with nitrogen to form Si 3 N 4 . TiN and Si under bias 3 N 4 At the same time, a film is grown on the substrate to form a Ti-Si-N nanocomposite coating. Wherein the gas flow rate of nitrogen gas is 200 sccm; the flow rate of silane gas is 350 sccm, and the SiH gas flow rate of the vacuum chamber 4 The flow of gas a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com