Manufacture of prefabricated fiber rod

An optical fiber preform and a manufacturing method technology, which is applied to manufacturing tools, glass manufacturing equipment and other directions, can solve the problems of long equipment occupation time, low production efficiency, increased cost of sleeves, etc., so as to achieve short equipment occupation time, improve production efficiency, High deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

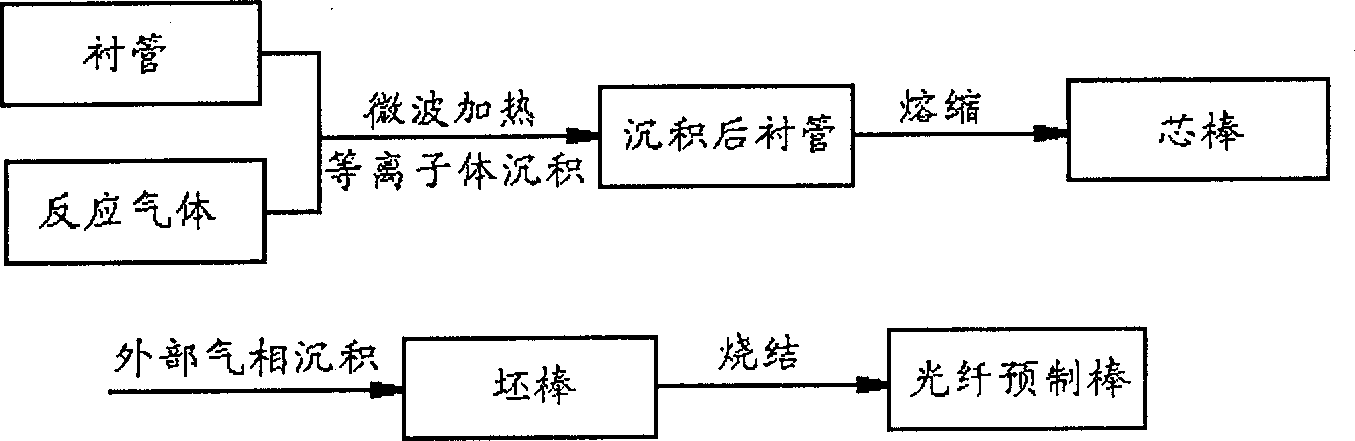

[0018] The manufacturing method of the present invention will be further described below in conjunction with the accompanying drawings.

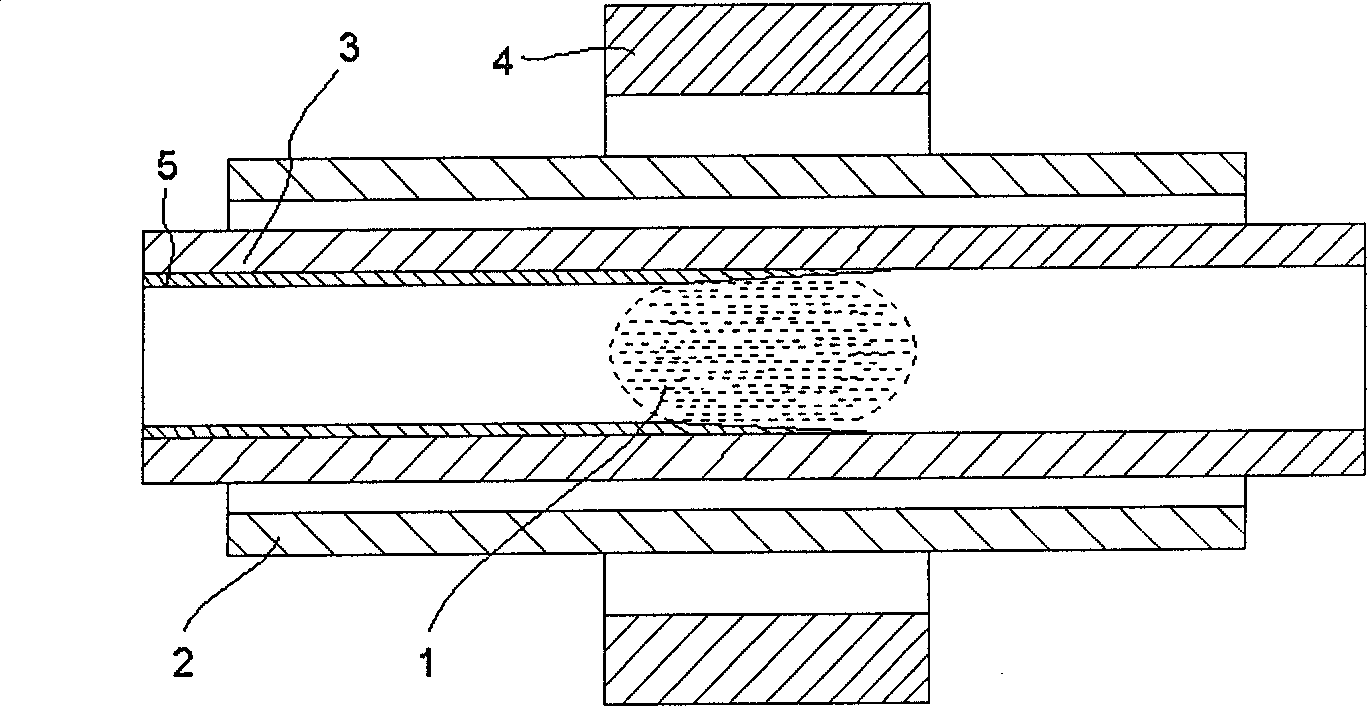

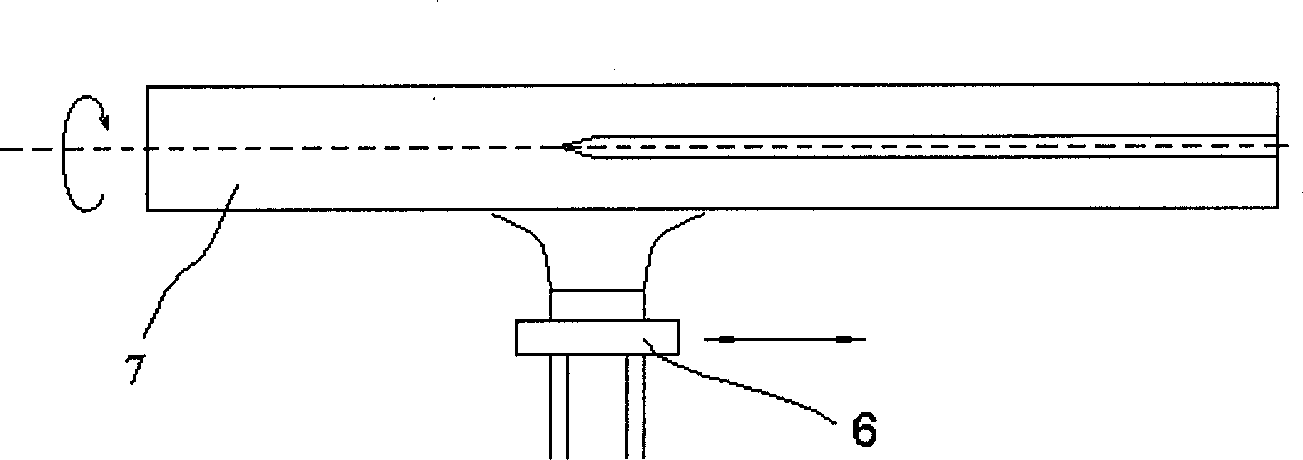

[0019] Such as Figure 1 to Figure 6 As shown, the present invention firstly passes the parent material into a rotating quartz glass liner 3, and the resonant cavity 4 couples microwaves to the reaction gas in the liner 3 to excite it into plasma 1, which is deposited in the liner 3 A glassy deposition layer 5 is formed on the surface. When sufficient layers of glass-breaking film are deposited in the liner 3, the liner is heated in a heat source 6 to melt and shrink it into a solid preform, which is the mandrel 7. Then, the reaction raw material is sent to the burner 8 through the conveying system by the vapor phase deposition method outside the tube, and the flame hydrolysis is carried out with the oxyhydrogen flame 9 containing the reaction raw material, and SiO2 dust 11 is deposited on the mandrel. Hang the billet vertically on the grab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com