Method for preparing microlite silicon

A technology of microcrystalline silicon and amorphous silicon thin film, which is applied in the field of silicon materials to convert amorphous silicon into microcrystalline silicon, can solve the problems of low mobility, low photoelectric conversion efficiency, and low growth rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments.

[0020] A 50nm-thick hydrogenated amorphous silicon film (a-Si:H) was deposited on glass by plasma-enhanced chemical vapor deposition (PECVD), the substrate temperature was 220°C, and the RF power density was 0.03W / cm 2 , the gas flow rate is 15 sccm, and the reaction chamber pressure is 80Pa.

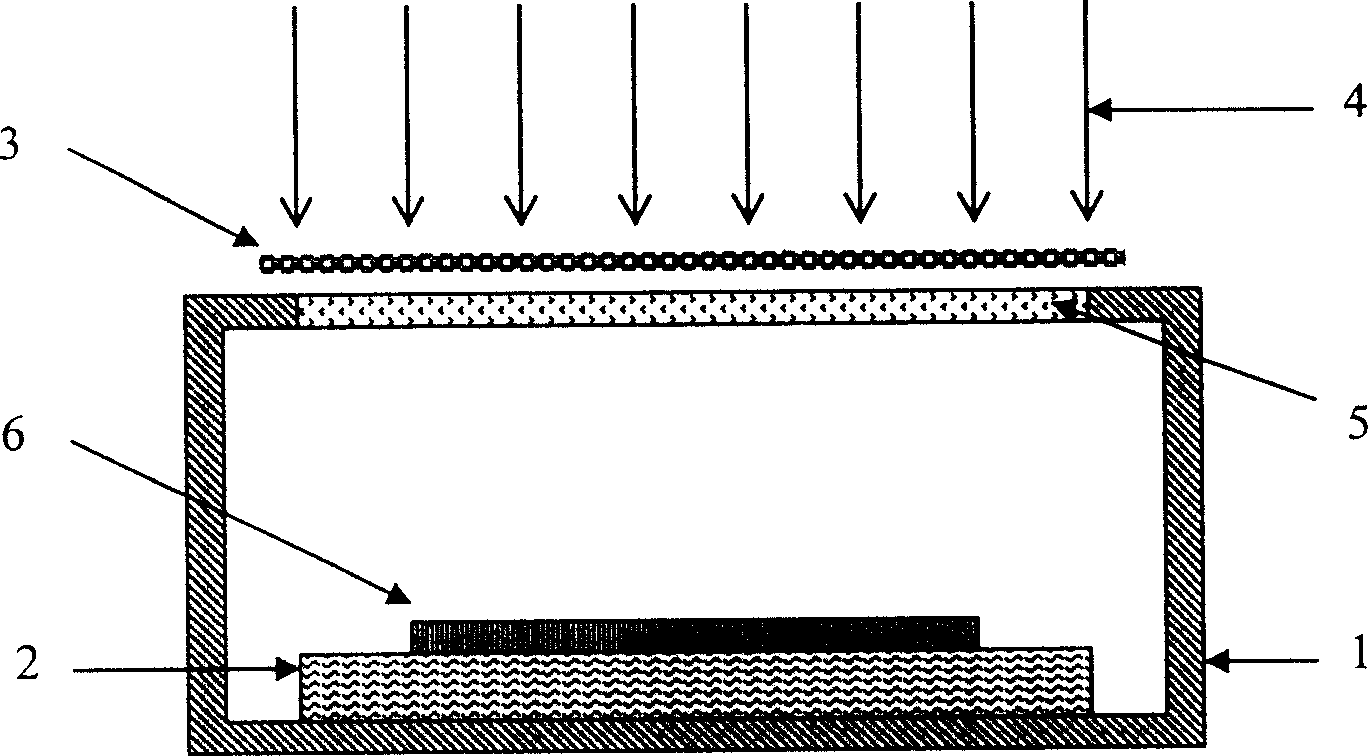

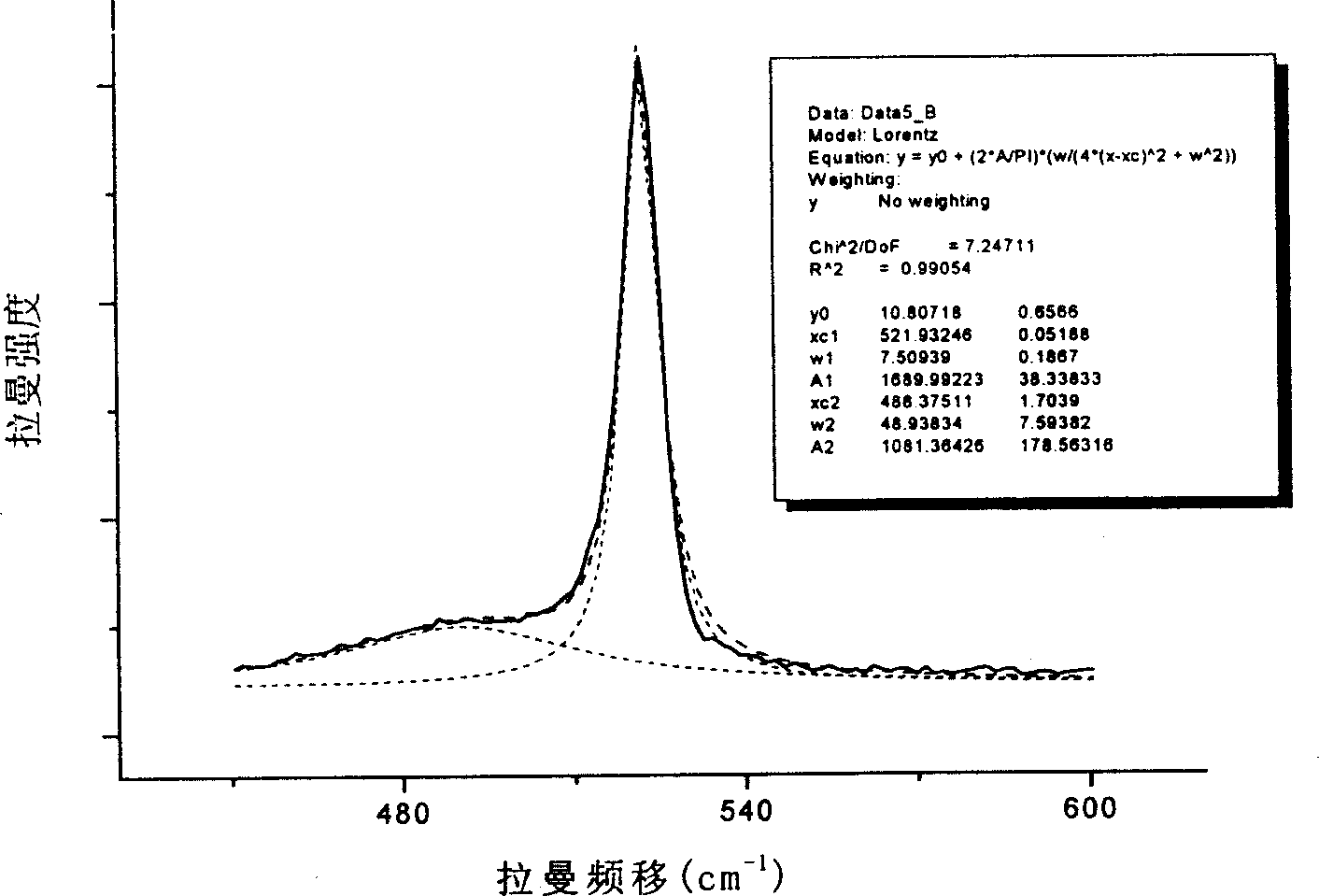

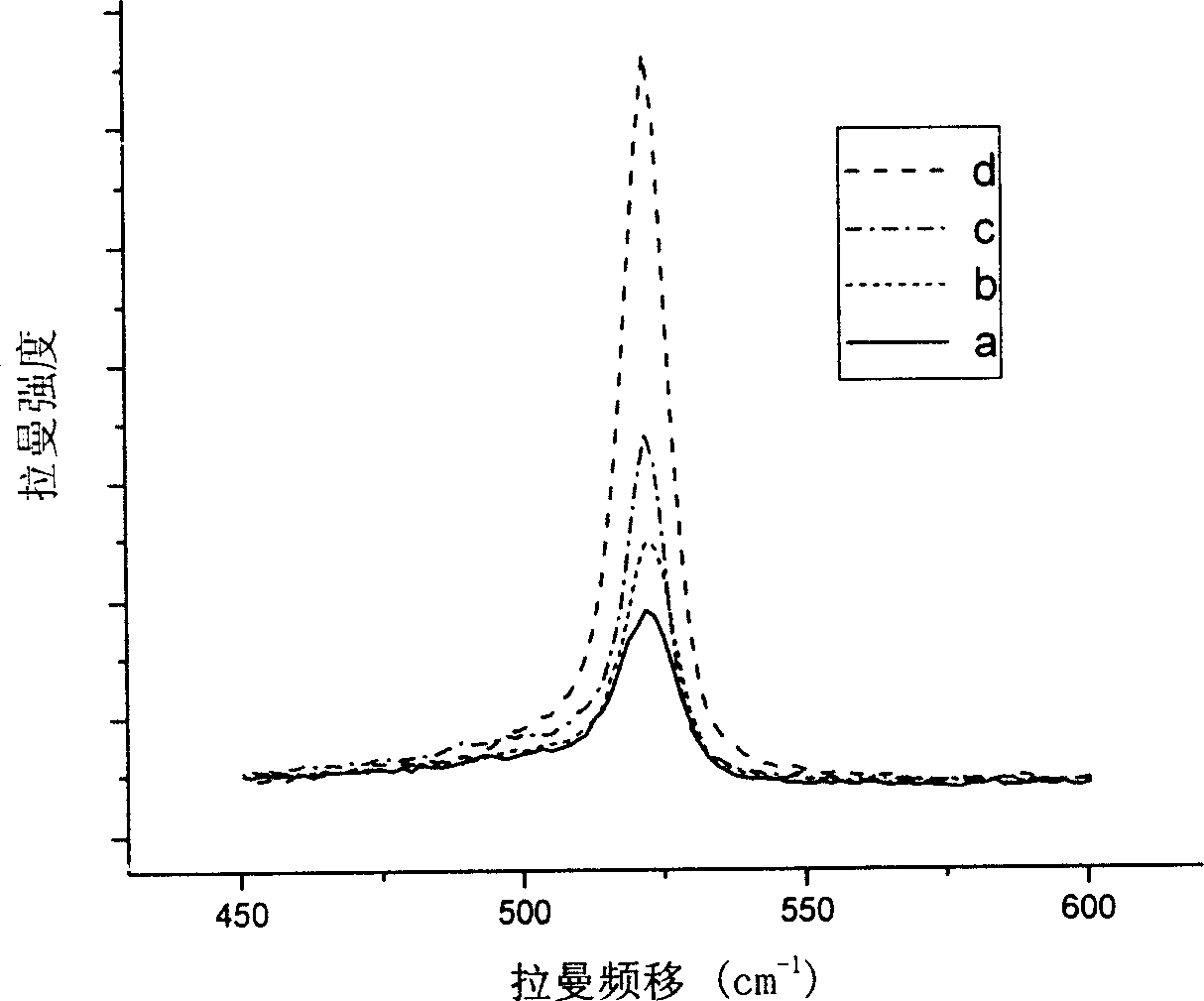

[0021] The above-mentioned hydrogenated amorphous silicon thin film sample 6 is placed on the figure 1 On the heating plate 2 at the bottom of the vacuum annealing furnace 1 shown, after the window 5 is covered, the annealing furnace is evacuated; when the vacuum degree reaches 2Pa, the power supply of the heating plate 2 is turned on for heating, and the ultraviolet light source 4 is turned on at the same time; the sample 6 When the set temperature reaches 400°C, the UV illuminance of the UV light source 4 is stable at 1mW / cm 2 , remove the cover on the window 5, let the ultraviol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com