Preparation method for iron-doped tungsten trioxide photoelectrode

A tungsten trioxide and iron doping technology, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of difficult to control the morphology of materials, complex equipment experimental procedures, hindering general application, etc., to achieve large-scale industrial production, The effect of simple experimental equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

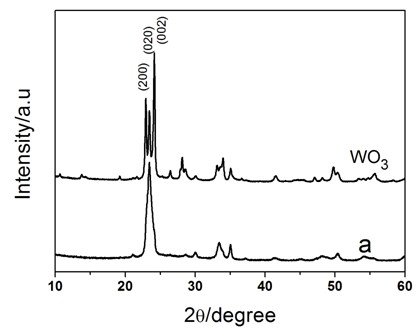

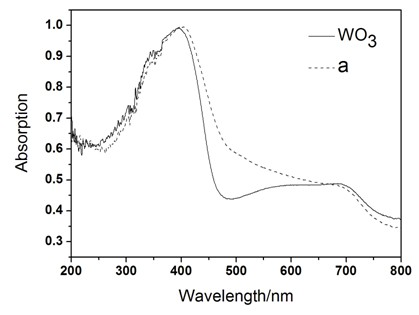

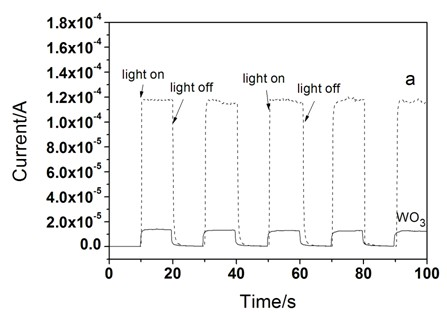

[0016] The preparation method of iron-doped tungsten trioxide photoelectrode comprises the following steps:

[0017] 1) Preparation of amorphous tungsten oxide film: 0.0025~0.0100mol of Na 2 WO 4 Dissolve in 50mL of distilled water, add 0.25~1.00mL of 30% H 2 o 2 Solution, then add 30mL of isopropanol, stir for 1 minute to get 2 o 7 2- After the solution, use 2mol / L perchloric acid or nitric acid to adjust the content of W 2 o 7 2- The pH value of the solution is 1.10~1.40, add distilled water to contain W 2 o 7 2- solution to a volume of 100mL, to obtain a clear electrolyte; with ITO conductive glass as the working electrode, the platinum electrode as the counter electrode, and the saturated calomel electrode as the reference electrode, placed in the electrolyte for electrodeposition, relative to the calomel electrode The cathode potential is -0.4~-0.6V, and the deposition time is 60 minutes to obtain an amorphous tungsten oxide film, which is dried for later use; ...

Embodiment 1

[0021] 1) Preparation of amorphous tungsten oxide film: 0.0025mol of Na 2 WO 4 Dissolve in 50mL of distilled water, add 0.25mL of 30% H 2 o 2 Solution, then add 30mL of isopropanol, stir for 1 minute to get 2 o 7 2- After the solution, use 2mol / L perchloric acid to adjust the content of W 2 o 7 2- The pH value of the solution is 1.10, add distilled water to contain W 2 o 7 2- solution to a volume of 100mL, to obtain a clear electrolyte; with ITO conductive glass as the working electrode, the platinum electrode as the counter electrode, and the saturated calomel electrode as the reference electrode, placed in the electrolyte for electrodeposition, relative to the calomel electrode The cathode potential is -0.4V, and the deposition time is 60 minutes to obtain an amorphous tungsten oxide film, which is dried for later use;

[0022] 2) Iron doping by impregnation method: place the amorphous tungsten oxide film obtained in step 1) in 0.005mol / L Fe(NO 3 ) 3 Immerse in ...

Embodiment 2

[0025] 1) Preparation of amorphous tungsten oxide film: 0.0100mol of Na 2 WO 4 Dissolve in 50mL of distilled water, add 1.00mL of 30% H 2 o 2 Solution, then add 30mL of isopropanol, stir for 1 minute to get 2 o7 2- After the solution, use 2mol / L nitric acid to adjust the content of W 2 o 7 2- The pH value of the solution is 1.40, add distilled water to contain W 2 o 7 2- solution to a volume of 100mL, to obtain a clear electrolyte; with ITO conductive glass as the working electrode, the platinum electrode as the counter electrode, and the saturated calomel electrode as the reference electrode, placed in the electrolyte for electrodeposition, relative to the calomel electrode The cathode potential is -0.6V, and the deposition time is 60 minutes to obtain an amorphous tungsten oxide film, which is dried for later use;

[0026] 2) Iron doping by impregnation method: place the amorphous tungsten oxide film obtained in step 1) in 0.005mol / L Fe(NO 3 ) 3 Immerse in the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com