Carbon nano tube-doped poly-schiff base/ carbonyl iron powder composite stealth material

A technology of carbon nanotubes and carbonyl iron powder, which is applied in the field of carbon nanotube doped poly-Schiff base/carbonyl iron powder composite stealth materials, can solve the problems of general wave-absorbing effect, narrow wave-absorbing frequency band, narrow frequency band, etc., and achieve Good microwave absorption effect, wide absorption frequency band, and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

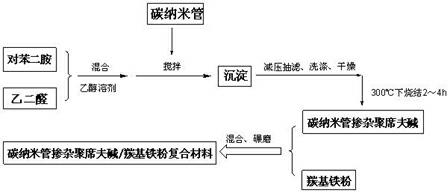

Method used

Image

Examples

Embodiment 1

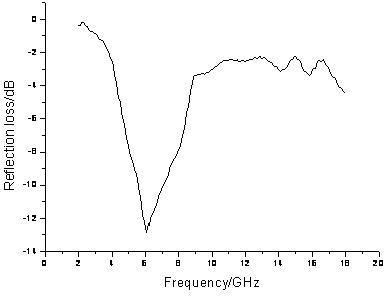

[0020] Dissolve 0.2 mol p-phenylenediamine and 0.2 mol glyoxal in 300 ml ethanol solution, then add 10.6 g carbon nanotubes, and react with electromagnetic stirring at 50° C. for 8 h. The resulting product was filtered under reduced pressure, rinsed with ethanol for 2 to 3 times, dried and sintered at 300°C for 2 to 4 hours to obtain carbon nanotube-doped poly-Schiff base; Carbonyl iron powder mixed with 16.7g of carbonyl iron powder evenly to obtain carbon nanotube doped poly-Schiff base / carbonyl iron powder composite stealth material, wherein the carbonyl iron powder preferably has an average particle size of less than 3.5um. The composite stealth material is composed of carbon nanotubes: 11%, poly-Schiff base: 27%, and the rest is carbonyl iron powder. The composite cloaking material powder is blended with paraffin wax to prepare a compound, the composite cloaking material accounts for 50% by weight of the whole compound, and the rest is paraffin wax. The composite is coat...

Embodiment 2

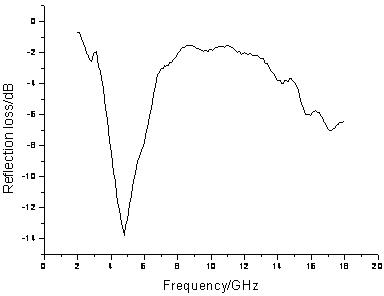

[0022] 0.2 mol p-phenylenediamine and 0.2 mol glyoxal were dissolved in 300 ml ethanol solution, then 7.5 g carbon nanotubes were added, and reacted with electromagnetic stirring at 50° C. for 10 h. The resulting product was filtered under reduced pressure, rinsed with ethanol for 2 to 3 times, dried and sintered at 300°C for 2 to 4 hours to obtain carbon nanotube-doped poly-Schiff base; The carbon nanotube doped poly-Schiff base / carbonyl iron powder composite stealth material was obtained by uniformly mixing the Schiff base with 16.7 g carbonyl iron powder. Among them, the carbonyl iron powder preferably has an average particle size of less than 3.5um. The composite stealth material is composed of carbon nanotubes: 8%, poly-Schiff base: 29%, and the rest is carbonyl iron powder. The composite cloaking material powder is blended with paraffin wax to prepare a compound, the composite cloaking material accounts for 50% by weight of the whole compound, and the rest is paraffin w...

Embodiment 3

[0024] 0.2 mol p-phenylenediamine and 0.2 mol glyoxal were dissolved in 300 ml ethanol solution, then 5.28 g carbon nanotubes were added, and reacted with electromagnetic stirring at 50° C. for 10 h. The resulting product was filtered under reduced pressure, rinsed with ethanol for 2 to 3 times, dried and sintered at 300°C for 2 to 4 hours to obtain carbon nanotube-doped poly-Schiff base; The carbon nanotube doped poly-Schiff base / carbonyl iron powder composite stealth material was obtained by uniformly mixing the Schiff base with 16.7 g carbonyl iron powder. Among them, the carbonyl iron powder preferably has an average particle size of less than 3.5um. The composite stealth material is composed of carbon nanotubes: 6%, poly-Schiff base: 31%, and the rest is carbonyl iron powder. The composite cloaking material powder is blended with paraffin wax to prepare a compound, the composite cloaking material powder accounts for 50% by weight of the whole compound, and the rest is pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com