Method for efficiently preparing low-cost carbonized brick by utilizing steel slags

A low-cost, carbonized brick technology, applied in the field of comprehensive utilization of resources, can solve the problems of difficult utilization of steel slag carbonized products, low efficiency and high preparation cost, and achieve the effects of accelerating carbonization rate, flexible operation and high carbonization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

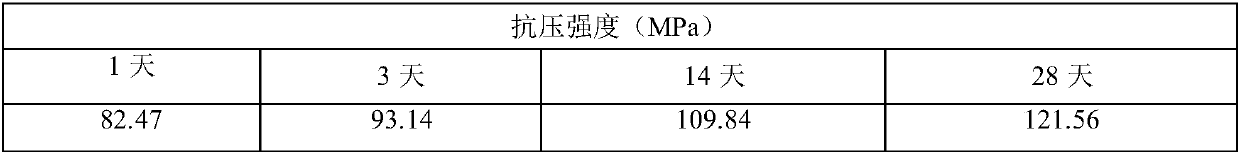

Embodiment 1

[0035] Step 1. Dry the steel slag to a moisture content of 0-1%, and grind the dried steel slag to a specific surface area of 400kg / m 2 and 600kg / m 2 Two parts; and mix uniformly according to the mass ratio of 1:1 to prepare the steel slag mixture; dry the desulfurized gypsum to a moisture content of 0-1%, and grind the dried desulfurized gypsum to a specific surface area of 650kg / m 2 ;Dry the iron tailings to a moisture content of 0-1%, and grind the dried iron tailings to a specific surface area of 450kg / m 2 ;

[0036] Step 2. The raw materials prepared in step 1 are prepared according to the dry basis weight percentage according to 84.6% of steel slag, 5.4% of desulfurized gypsum, and 10% of iron tailings to obtain a mixed dry material, and add 20% of the total mass of the mixed dry material to the mixed dry material. Water was stirred for 180 seconds to obtain mixed wet powder;

[0037] Step 3. Weigh a certain amount of the mixed wet powder obtained in Step 2 and ...

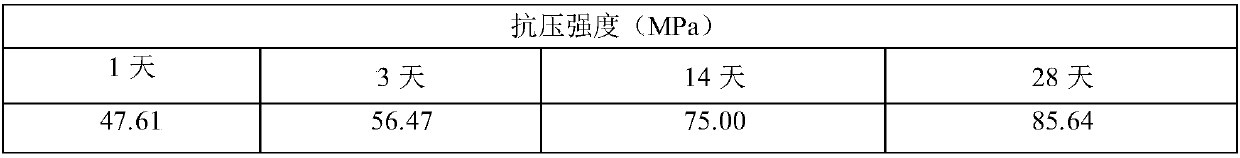

Embodiment 2

[0042] Step 1. Dry the steel slag to a moisture content of 0-1%, and grind the dried steel slag to a specific surface area of 400kg / m 2 and 600kg / m 2 Two parts; and mix uniformly according to the mass ratio of 1:1 to prepare the steel slag mixture; dry the desulfurized gypsum to a moisture content of 0-1%, and grind the dried desulfurized gypsum to a specific surface area of 650kg / m 2 ;Dry the ultrabasic rock iron tailings to a moisture content of 0-1%, and grind the dried iron tailings to a specific surface area of 450kg / m 2 ;

[0043] Step 2. The raw materials prepared in step 1 are prepared according to the dry basis weight percentage according to 47% of steel slag, 3% of desulfurized gypsum, and 50% of iron tailings to obtain a mixed dry material, and add 20% of the total mass of the mixed dry material to the mixed dry material. Water was stirred for 180 seconds to obtain mixed wet powder;

[0044] Step 3. Weigh a certain amount of the mixed wet powder obtained in...

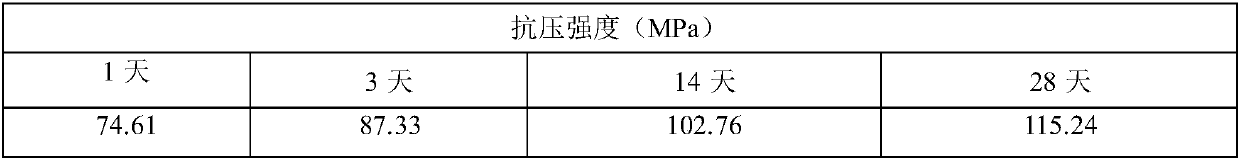

Embodiment 3

[0049] Step 1. Dry the steel slag to a moisture content of 0-1%, and grind the dried steel slag to a specific surface area of 400kg / m 2 and 600kg / m 2 Two parts; mix uniformly according to the mass ratio of 1:1.5 to prepare steel slag mixture; dry the desulfurized gypsum to a moisture content of 0-1%, and grind the dried desulfurized gypsum to a specific surface area of 650kg / m 2 ;Dry the river sand to a moisture content of 0-1%;

[0050] Step 2: Mix the raw materials prepared in step 1 with 84.6% of steel slag, 5.4% of desulfurized gypsum, and 10% of river sand to obtain a mixed dry material by weight percentage on a dry basis, and add water accounting for 15% of the total mass of the mixed dry material to the mixed dry material. Stir for 180 seconds to obtain mixed wet powder;

[0051] Step 3. Weigh a certain amount of the mixed wet powder obtained in Step 2 and put it into a molding mold for compression molding, hold the pressure for 1 minute under a molding pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com