Method for preparing carbonized brick from wet-milling carbide slag

A technology of carbide slag and carbonized bricks, which is applied in the field of comprehensive utilization of resources, can solve the problems of difficult industrial utilization of carbonized products, low utilization rate of industrial solid waste carbide slag, and high preparation cost, and achieves good volume stability and high compressive strength. , the effect of low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

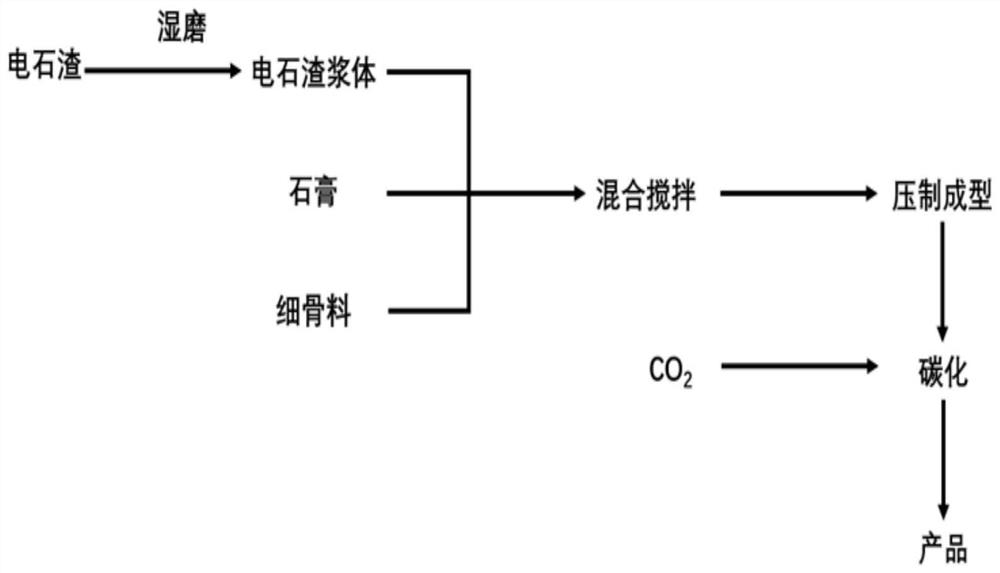

Method used

Image

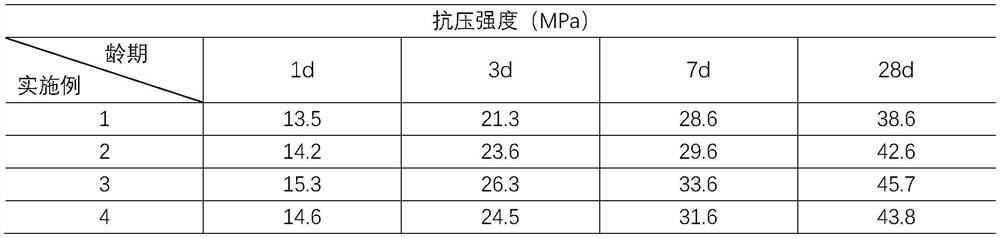

Examples

Embodiment 1

[0044] Step 1. Add 150 parts of carbide slag, 75 parts of water, 0.5 to 3 parts of grinding aid, and add them to the wet mixing mill for wet grinding. The wet grinding time is 0.5, the speed is 400r / min, and the ratio of grinding media ceramic balls is 1.2mm :0.8mm:0.6mm=2:4:4, obtain the wet ground carbide slag slurry of median particle size D(50)=3 μ m;

[0045] Step 2. Take 120 parts of wet-milled calcium carbide slag slurry, 5 parts of desulfurized gypsum, 50 parts of slag, 420 parts of river sand, and iron tailings mixed fine aggregate in step 1, and mix and stir for 90 seconds to obtain a mixed mortar;

[0046] Step 3. Weigh the mixed mortar obtained in step 2 and put it into a molding mold for compression molding. The molding pressure of compression molding is 2MPa, the pressure holding time is 30s, and the mold is demoulded immediately after molding;

[0047] Step 4. Put the demoulded test block in step 3 into a constant temperature and humidity carbonization chamber f...

Embodiment 2

[0049] Step 1. Add 175 parts of carbide slag, 87.5 parts of water, 2 parts of polycarboxylate superplasticizer and aliphatic high-efficiency superplasticizer mixed solution, and add it to the wet mixing mill for wet grinding. The wet grinding time is 0.8h and the speed is 400r / min. , the grinding medium ceramic ball proportioning is 1.2mm:0.8mm:0.6mm=2:4:4, obtains the wet grinding carbide slag slurry of median diameter D (50)=2.3 μ m;

[0050] Step 2. Take 150 parts of wet-milled calcium carbide slag slurry in step 1, 15 parts of phosphogypsum, 85 parts of slag, 600 parts of river sand, mixed fine aggregate of sedimentary sand, and 10 parts of water, and mix and stir for 90 to 180 seconds to obtain a mixed mortar;

[0051] Step 3. Weigh the mixed mortar obtained in step 2 and put it into a molding mold for compression molding. The molding pressure of compression molding is 2-35MPa, the holding time is 30-60s, and the mold is demoulded immediately after molding;

[0052] Step...

Embodiment 3

[0054] Step 1. Add 225 parts of calcium carbide slag, 112.5 parts of water, 2 parts of polycarboxylate superplasticizer, calcium lignosulfonate superplasticizer mixed solution, and add it to the wet mixing mill for wet grinding. The wet grinding time is 1h and the speed is 400r / min, the grinding medium ceramic ball proportioning is 1.2mm:0.8mm:0.6mm=2:4:4, obtains the wet grinding carbide slag slurry of median particle diameter D (50)=0.9 μ m;

[0055] Step 2. Take 175 parts of wet-milled calcium carbide slag slurry in step 1, 27 parts of a mixture of desulfurized gypsum and phosphogypsum, 100 parts of slag, 731 parts of river sand, mixed fine aggregate of tailings sand, 14 parts of water, and mix and stir for 120 seconds , to get mixed mortar;

[0056] Step 3. Weigh the mixed mortar obtained in step 2 and put it into a molding mold for compression molding. The molding pressure of compression molding is 30MPa, the pressure holding time is 45s, and the mold is demoulded immedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com