Spinneret plate, profiled nylon 6 fiber and making method thereof

A spinneret and special-shaped technology, applied in fiber treatment, filament/thread forming, single-component polyamide artificial filament, etc., can solve the problems of poor gloss, water absorption and moisture permeability of special-shaped nylon 6 fibers, etc. , to achieve the effect of luster, moisture absorption and perspiration, enhanced capillary effect, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing special-shaped nylon 6 fibers, which comprises melting polyamide 6 dry slices with a relative viscosity of 2.40-2.70 to obtain a polyamide 6 melt, the melting temperature being 250-270°C; melting the polyamide 6 The body is extruded through the spinneret microholes 2 on the above-mentioned spinneret to obtain polyamide 6 fiber tow, and the polyamide 6 fiber tow is sequentially subjected to monomer suction, side blowing cooling, cluster oiling, drawing Stretching and network interlacing, and then winding to obtain the special-shaped nylon 6 fiber.

[0028] As can be seen from the foregoing description, the beneficial effects of the present invention are:

[0029] (1) By the above-mentioned special-shaped cross-section design of the spinneret microhole of the spinneret, the cross-section presents a double-edged zigzag as a whole, so that the cross-section of the special-shaped nylon 6 fiber prepared by the spinneret of the present invention is a dou...

Embodiment 1

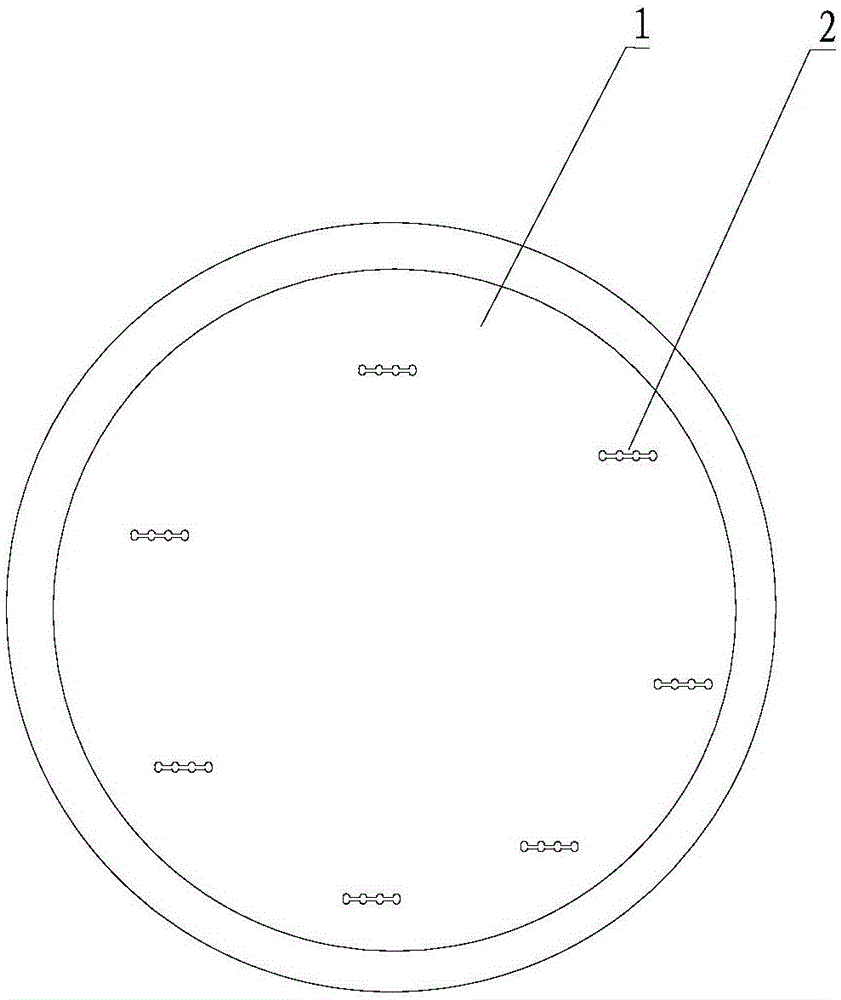

[0052] Please refer to Figure 1-3 , Embodiment 1 of the present invention is:

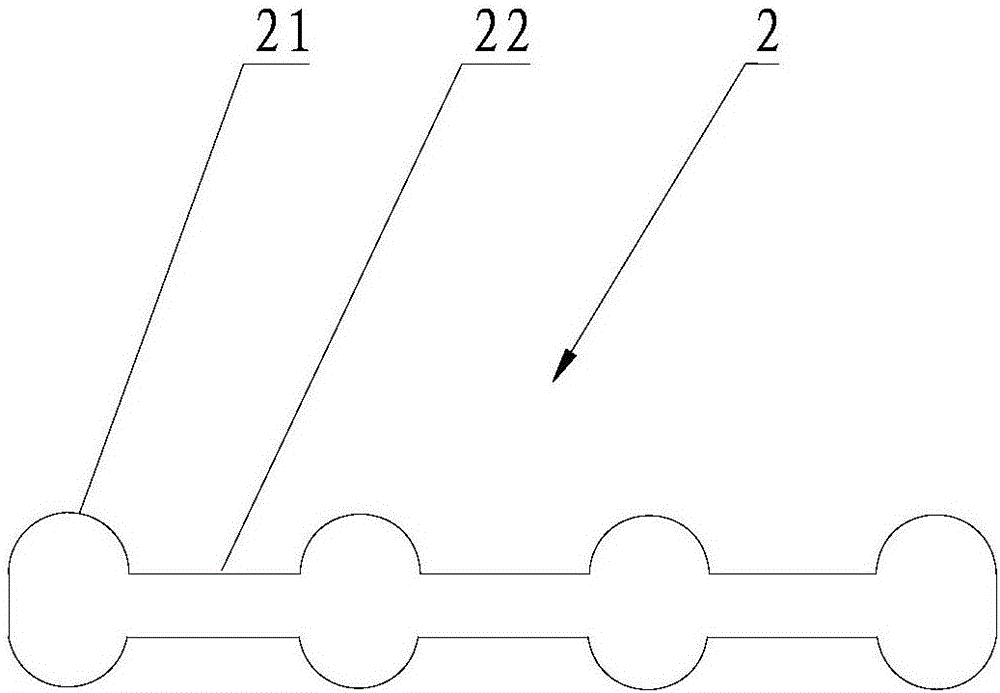

[0053] A spinneret, comprising a substrate 1 and seven spinneret holes 2, the spinneret holes 2 are arranged on the substrate 1, the cross section of the spinneret holes 2 is a sawtooth structure, and the sawtooth The structure includes two sawtooth parts, the sawtooth part includes four semicircle arcs 21 with the same radius, the four semicircle arcs 21 are arranged in sequence, and a straight line 22 passes between two adjacent semicircle arcs 21 The two serrated parts are connected to each other to form a symmetrical closed structure, and the four semicircular arcs 21 on one serrated part correspond to the four semicircular arcs 21 on the other serrated part. The distance between the centers of two adjacent semicircular arcs 21 in the serrated portion is 4 times the radius, and the distance between the centers of two semicircular arcs 21 correspondingly arranged in the two serrated portions i...

Embodiment 2

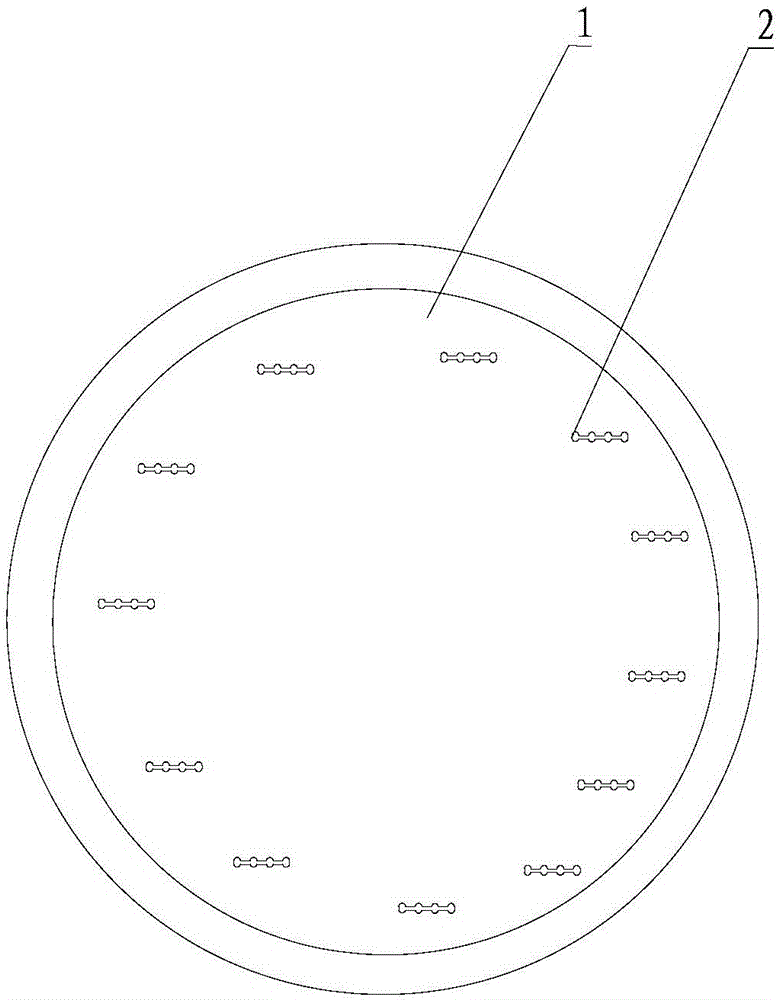

[0057] Please refer to Figure 1-3 , the second embodiment of the present invention is:

[0058] A spinneret, only "the number of spinneret microholes 2 is 12, and the distance between the centers of two adjacent semicircular arcs 21 in the serrations is 4.2 times the radius, The distance between the centers of the two semicircular arcs 21 that are set correspondingly is 1.2 times the radius" is different from the first embodiment, and the others are the same as the first embodiment.

[0059] A special-shaped nylon 6 fiber is obtained by extruding polyamide 6 slices through the spinneret micro-holes 2 on the above spinneret to obtain the special-shaped nylon 6 fiber.

[0060] A method for preparing special-shaped polyamide 6 fibers. The polyamide 6 dry chips with a relative viscosity of 2.70 are sent to a screw extruder through a pipeline for melting, mixing, compression and extrusion to obtain a polyamide 6 melt. The melting, kneading, compression and extrusion temperatures...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com