Reinforced essence for baking aromatic tobacco and preparation method for reinforced essence

A technology of adding essence and oriental tobacco, which is applied in the preparation of tobacco, essential oil/spices, tobacco, etc., can solve the problems of obvious characteristics of oriental tobacco and the inability to use flue-cured tobacco cigarettes, etc., and achieve rich aroma, small residue, soft and delicate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

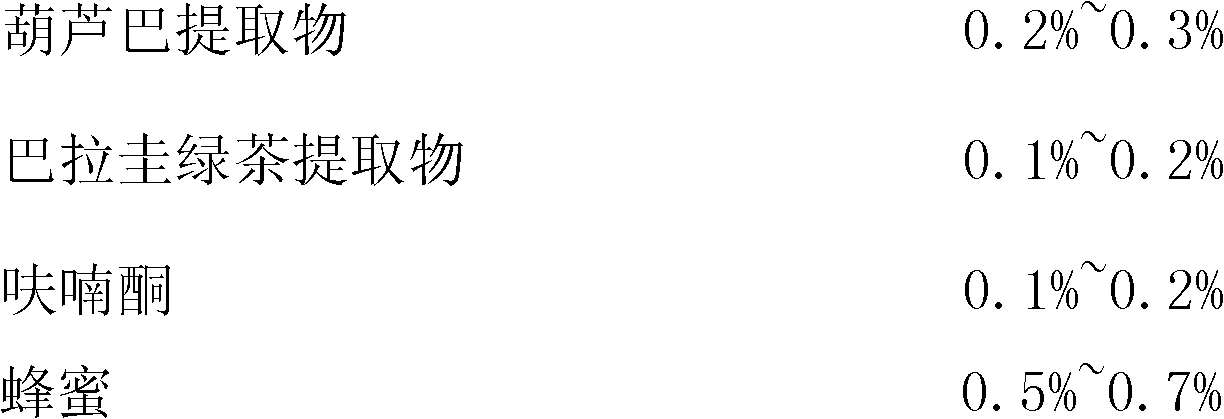

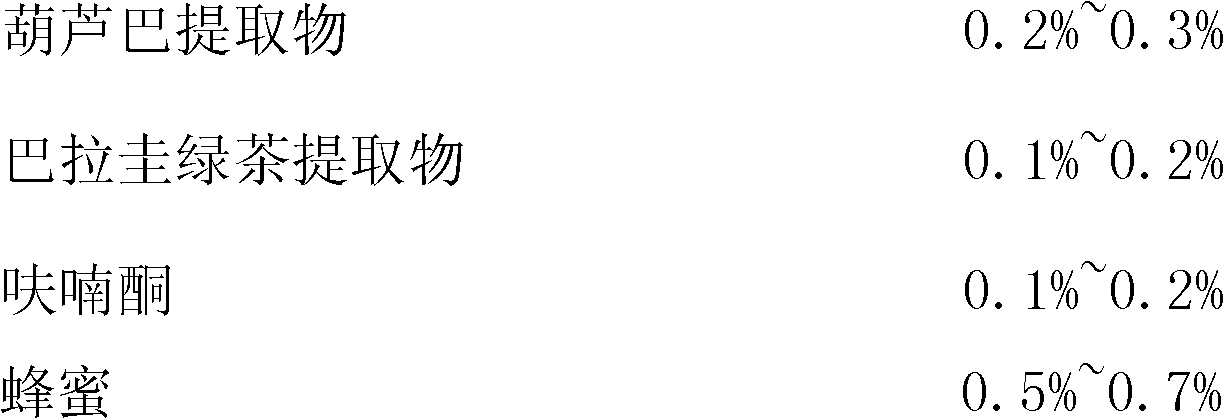

[0023] According to the percentage by weight of shredded tobacco, prepare the flavor of the lining: 0.5% propylene glycol, 0.3% of sorbitol; prepare the essence of the surface material according to the percentage by weight of shredded tobacco: 0.2% of fenugreek extract, 0.1% of Paraguay green tea extract, 0.2% of furanone, 0.5% of honey, Stir well separately. The lining essence is applied to the tobacco leaves in an amount of 15% by weight in the oriental tobacco leaf segment, and the surface material essence is applied to the shredded leaf in an amount of 5% by weight in the oriental tobacco cut leaf segment.

[0024] Fragments of oriental tobacco leaves:

[0025] (1) The tobacco sheet regains moisture and sends the flavored tobacco sheet to a loose moisture regain machine for increasing temperature and humidification;

[0026] (2) Lining: Screen the remoisturized oriental tobacco sheets, add flavoring essence to the tobacco sheets, the application amount is 15% of the weigh...

specific Embodiment approach 2

[0032] According to the percentage by weight of shredded tobacco, prepare the flavor of lining: 0.5% propylene glycol, 0.3% of sorbitol; prepare the flavor of the surface according to the percentage by weight of shredded tobacco: 0.25% of fenugreek extract, 0.1% of Paraguayan green tea extract, 0.15% of furanone, 0.5% of honey, Stir well separately. The lining essence is applied to the tobacco leaves in an amount of 15% by weight in the oriental tobacco leaf segment, and the surface material essence is applied to the shredded leaf in an amount of 5% by weight in the oriental tobacco cut leaf segment.

[0033] The specific method of applying the flavoring essence is:

[0034] Fragments of oriental tobacco leaves:

[0035] (1) The tobacco sheet regains moisture and sends the flavored tobacco sheet to a loose moisture regain machine for increasing temperature and humidification;

[0036] (2) Lining: Screen the remoisturized oriental tobacco sheets, add flavoring essence to the ...

specific Embodiment approach 3

[0042] According to the weight percentage of shredded tobacco, prepare the flavor of the lining: 0.5% propylene glycol, 0.3% sorbitol; prepare the flavoring essence according to the weight percentage of shredded tobacco: 0.2% of fenugreek extract, 0.1% of Paraguay green tea extract, 0.2% of furanone, 0.6% of honey, Stir well separately. The lining essence is applied to the tobacco leaves in an amount of 15% by weight in the oriental tobacco leaf segment, and the surface material essence is applied to the shredded leaf in an amount of 5% by weight in the oriental tobacco cut leaf segment.

[0043] The concrete application method of this flavoring essence is with the embodiment:

[0044] Fragments of oriental tobacco leaves:

[0045] (1) The tobacco sheet regains moisture and sends the flavored tobacco sheet to a loose moisture regain machine for increasing temperature and humidification;

[0046] (2) Lining: Screen the remoisturized oriental tobacco sheets, add flavoring esse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com