Blue-green series pigment with pearlescent effect and preparation method of pigment

A technology of pearlescent pigments and blue pigments, which is applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc. It can solve the problems that the preparation method has not been reported in the literature, it is not suitable for coloring of pearlescent pigments, and the luster of pearlescent pigments is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

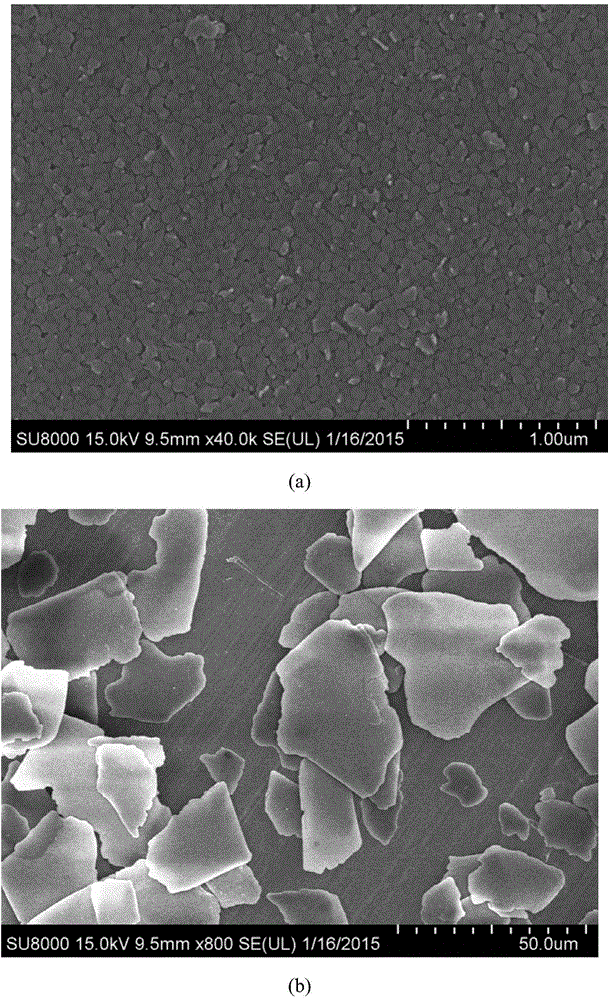

Image

Examples

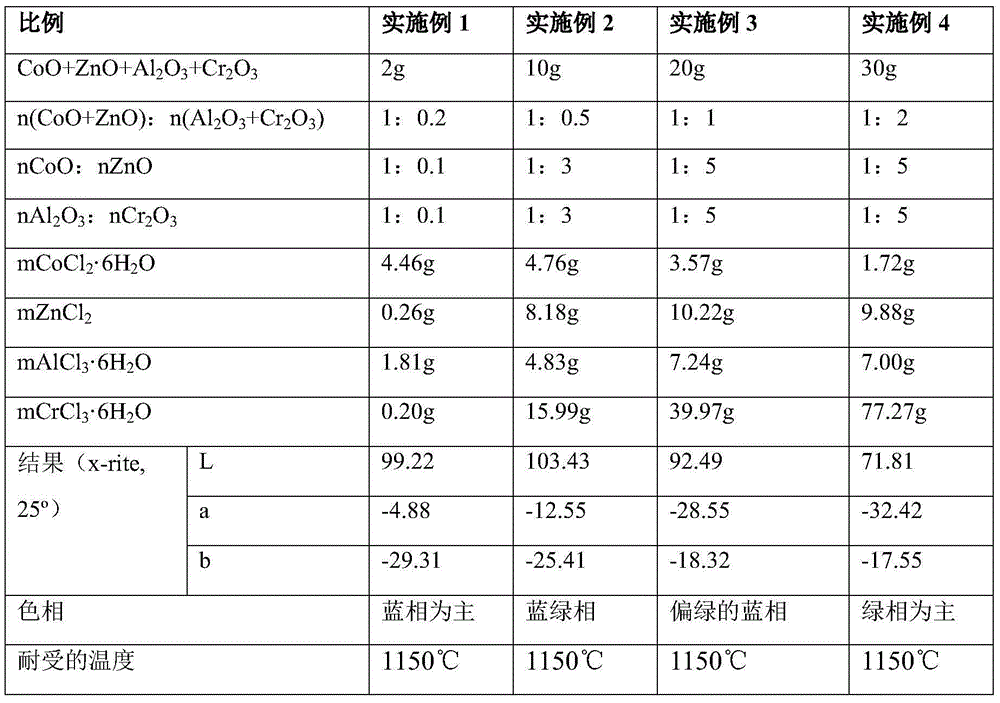

Embodiment 1

[0059] (1) Take 100 g of natural mica with a particle size of 10-60 microns, put it into a reaction kettle with a volume of 2 L, add 1000 milliliters of deionized water, and stir to make it evenly dispersed into a suspension;

[0060] (2) Heating the suspension in a constant temperature water bath and stabilizing it at 60°C, adjusting the pH of the suspension to 1.4 with 16% dilute hydrochloric acid;

[0061] (3) Add 100g of 2% SnCl 4 ·5H 2 O solution, Sn was added dropwise at an unsteady pH, and stirred at constant temperature for 15 minutes after the addition was complete.

[0062] (4) Adjust the temperature to 70°C, and slowly adjust the pH to 1.6 with liquid caustic soda (30% NaOH aqueous solution). Add 0.5M TiCl dropwise 4 Solution, keep the pH value constant with 30% liquid caustic soda NaOH solution. Reaction to blue interference color, stirring at constant temperature for 30 min.

[0063] (5) Adjust the temperature of the suspension to 65° C. and the pH to 7.5. 4...

Embodiment 2

[0069] (1) Take 100 g of natural mica with a particle size of 10-30 microns, put it into a reactor with a volume of 2 L, add 1000 milliliters of deionized water, and stir to make it uniformly dispersed into a suspension;

[0070] (2) Heating the suspension in a constant temperature water bath and stabilizing it at 65° C., adjusting the pH of the suspension to 1.7 with 16% dilute hydrochloric acid;

[0071] (3) Add 100g of 5% SnCl 4 ·5H 2 O solution, stirred at constant temperature for 15 min after the addition was completed.

[0072] (4) Adjust the temperature to 75°C, slowly adjust the pH to 1.9 with 20% aqueous sodium carbonate solution, and add 1M TiCl dropwise 4 solution, the pH was kept constant with 20% sodium carbonate solution. Reaction to blue interference color, stirring at constant temperature for 30 min.

[0073] (5) Adjust the temperature of the suspension to 70° C. and the pH to 8.2. 4.76g CoCl 2 ·6H 2 O, 8.18g ZnCl 2 , 15.99gCrCl 3 ·6H 2 O and 4.83g Al...

Embodiment 3

[0079] (1) Take 100g of natural mica with a particle size of 10-100 microns, put it into a reactor with a volume of 2L, add 1000 milliliters of deionized water, and stir to make it evenly dispersed into a suspension;

[0080] (2) Heating the suspension in a constant temperature water bath and stabilizing it at 75° C., adjusting the pH of the suspension to 2.0 with 16% dilute hydrochloric acid;

[0081] (3) Add 200g of 4% SnCl 4 ·5H 2 O solution, Sn was added dropwise at an unsteady pH, and stirred at constant temperature for 15 minutes after the addition was complete.

[0082] (4) Adjust the temperature to 80° C., and slowly adjust the pH to 2.2 with 16% sodium sulfite solution. Add 2M TiCl dropwise 4 Solution, keep the pH constant with 16% sodium sulfite solution. Reaction to blue interference color, stirring at constant temperature for 30 min.

[0083] (5) Adjust the temperature of the suspension to 75° C. and the pH to 8.8. 3.57g CoCl 2 ·6H 2 O, 10.22g ZnCl 2 , 39....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com