A vacuum coating reflective product and its preparation process

A technology of vacuum coating and preparation process, applied in optics, optical components, instruments, etc., can solve the problems of uncontrollable thickness of coating layer, affecting the reflective brightness and dazzling effect of reflective products, unevenness, etc., and achieve high reflective brightness and dazzling effect. Color effect, improve market competitiveness, and effect of good coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 discloses a high brightness brilliant reflective cloth product preparation process, which comprises the following steps:

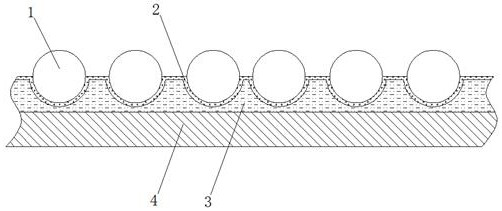

[0034] Step 1: Take the PET film as a protective film layer, and then coat the PET film with a layer of bead glue, after drying in the drying channel, sprinkle a layer of glass beads, and then wrap and set aside;

[0035]Step 2: Select pet film as the base film, send the PET film into the vacuum evaporation chamber, and vacuum coat the ET film with a layer of zinc sulfide coating with dazzling effect before use;

[0036] Step 3: Coat the zinc sulfide vacuum coating of the coating base film with solvent-based acrylic resin composite glue, after drying in the drying channel, perform the first hot pressing composite with the chemical fiber cloth substrate, and then peel off the PET base film before entering the second composite position, so that the zinc sulfide vacuum coating is transferred to the composite rubber surface of the chemical fiber ...

Embodiment 2

[0041] Example 2 discloses a process for preparing a purple reflective cloth product, which comprises the following steps:

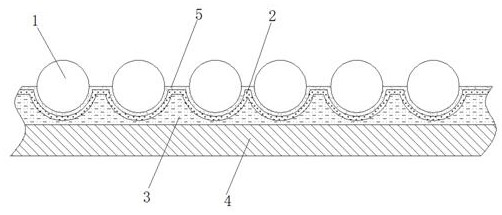

[0042] Step 1: Take the PE / PET composite film as the protective film layer, plant a layer of glass beads after the hot roller at 170 °C, and then coat a layer of acrylic resin transparent glue layer, dry it through the drying channel, and wrap it up and set aside;

[0043] Step 2: Take the PE / PET composite film as the base film, send the PE / PET composite film into the vacuum evaporation room, and vacuum evaporate a layer of copper plating on the PE film surface of its PE / PET composite film and set aside;

[0044] Step 3: Coat the copper coating of the coated base film with solvent-based polyurethane resin composite glue, dry it through the drying channel and then perform the first hot pressing composite with the TC cloth substrate, and then peel off the PE / PET base film before entering the second composite position, so that the copper coating is transferred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com