Shell material and preparation method thereof and shell button

A shell and button technology, applied in the field of dyeing, can solve the problems of poor color fastness, deterioration of natural dazzling color of shells, etc., and achieve the effects of high color fastness, simple preparation method and good dazzling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

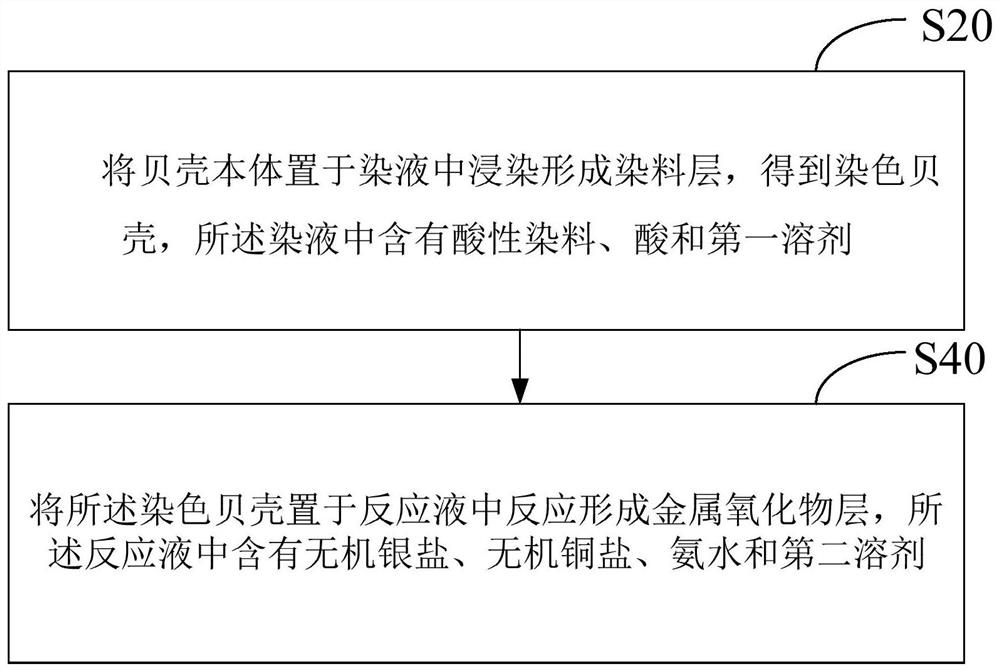

[0035] see figure 1 , the embodiment of the present invention also provides a preparation method of shell material, comprising:

[0036] S20, placing the shell body in a dye solution for dip-dyeing to form a dye layer to obtain a dyed shell, the dye solution containing acid dye, acid and a first solvent; and

[0037] S40, placing the dyed shell in a reaction solution to react to form a metal oxide layer, and the reaction solution contains inorganic silver salt, inorganic copper salt, ammonia water and a second solvent.

[0038] The preparation method of the shell material in the embodiment of the present invention is simple. First, the shell body is dyed with dye to form a dye layer, and then the chemical reaction of inorganic silver salt or inorganic copper salt and ammonia water is used to form silver oxide and copper oxide precipitation, so that the dye layer A metal oxide layer is formed on it. The preparation method of the shell material can be applied to industrialized...

Embodiment 1

[0052] S20, mixing acid dyes BLACK B, Navy R and acetic acid in water to obtain a dye solution. The concentration of acid dye BLACK B is 5g / L, the concentration of Navy R is 3g / L, and the concentration of acetic acid is 0.5ml / L. According to the shell button body: dye solution = 1:5 (mass ratio), the shell button body is placed in the dye solution at 100°C (above 95°C), and the machine rotates slowly and dyes at a constant temperature for 30 minutes to obtain dyed shell buttons. Finally, rinse the dyed shell buttons with clean water.

[0053] S40, mixing silver nitrate, copper sulfate and ammonia water in water to obtain a reaction liquid. The concentration of silver nitrate is 8g / L, the concentration of copper sulfate is 80g / L, and the concentration of ammonia water is 200ml / L. According to dyeing shell buttons: dyeing solution = 1:2 (mass ratio), add the dyed shell buttons obtained in S20 to the reaction solution, raise the temperature of the reaction solution to 40°C and ...

Embodiment 2

[0055] Embodiment 2 is basically the same as Embodiment 1, the difference is only in:

[0056] The acid dye in step S20 is LANASET YELLOW 2R with a concentration of 2g / L. That is to replace the acid dyes BLACK B and Navy R with LANASET YELLOW 2R.

[0057] In step S40, the reaction time at constant temperature is 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com